SiO2@PEI composite aerogel as well as preparation method and application thereof

A composite aerogel and gel technology, applied in the field of aromatic hydrocarbon processing, can solve problems such as low energy consumption and achieve the effect of improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: SiO with a feed ratio of PEI and tetraethyl orthosilicate of 1:100 2 @PEI Composite aerogels. Its preparation method is as follows:

[0028] 1) Polyethyleneimine is configured as 5% PEI aqueous solution;

[0029] 2) Put 10ml of ethanol, 8ml of tetraethyl orthosilicate and 2ml of water in a beaker, adjust its pH to about 2, stir at room temperature for 1.5h, and hydrolyze it to obtain an alcohol sol;

[0030] 3) Take 0.308 g of the PEI solution in step 1) and slowly add it to the alcohol sol obtained in step 2), and continue to stir for 10 minutes to mix it evenly to obtain a composite alcohol sol;

[0031] 4) Add 10% ammonia water to the composite alcohol sol obtained in step 3), adjust the pH to about 6, let it stand at room temperature, and wait for it to gel to obtain SiO 2 @PEI composite airgel;

[0032]5) Add 40ml of a mixed solution of tetraethyl orthosilicate and ethanol with a volume ratio of 15:25 to the composite airgel obtained in step 4), and ...

Embodiment 2-5

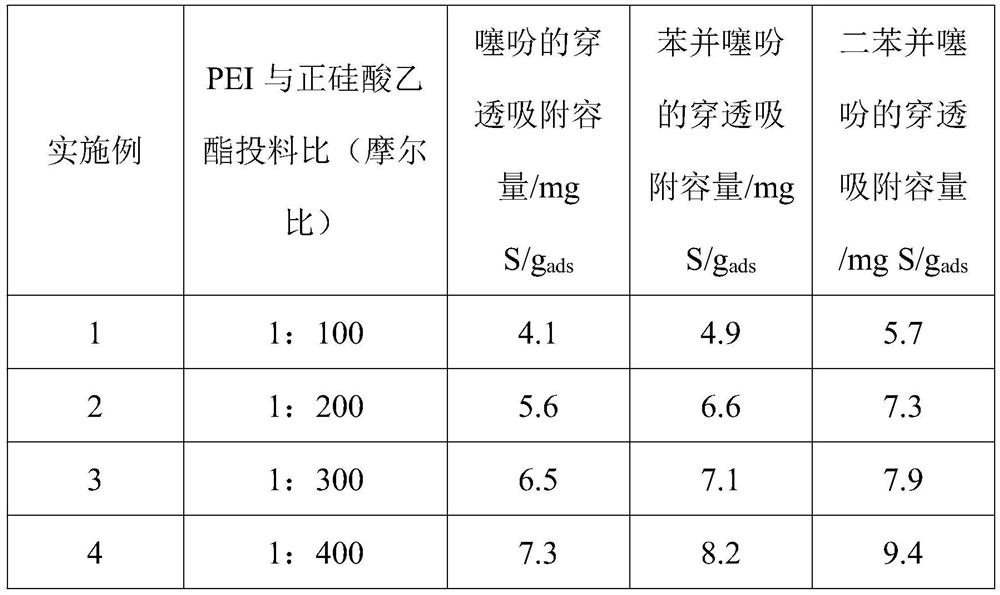

[0037] Example 2-5 SiO with PEI and tetraethyl orthosilicate ratios of 1:200, 1:300, 1:400, 1:500 respectively 2 @PEI Composite Airgel

[0038] The preparation steps and penetration adsorption experiment are the same as in Example 1, except that the quality of the PEI solution in Example 2 is 0.154g, the quality of the PEI solution in Example 3 is 0.103g, and the quality of the PEI solution in Example 4 is 0.077g. The mass of medium PEI is 0.0616g.

Embodiment 6-10

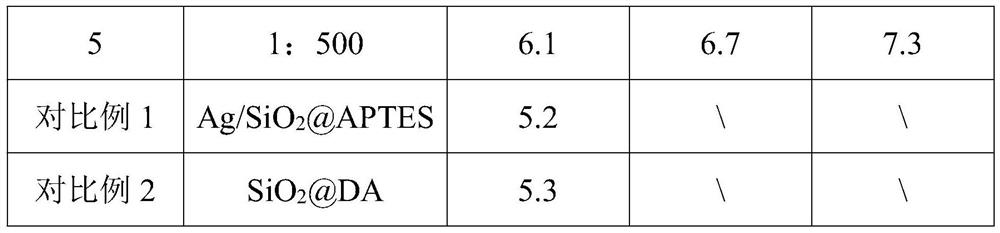

[0059] Embodiment 6-10: different space velocity to SiO 2 The effect of @PEI composite airgel on the sulfur adsorption performance of thiophenes in benzene solution. Select the SiO prepared by embodiment 4 2 @PEI Composite Airgel, the operation of the penetration adsorption experiment is the same as in Example 1-5, the difference is that the space velocity of the benzene solution is 1h respectively -1 ,2 -1 、4 -1 ,8 -1 、10 -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com