A kind of magnetic wave-absorbing fabric and its preparation method and application

A magnetic wave-absorbing and fabric technology, which is applied in textiles and papermaking, can solve the problems of easy agglomeration of wave-absorbing agents, and achieve the effects of reducing microwave absorption loopholes, good impedance matching, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

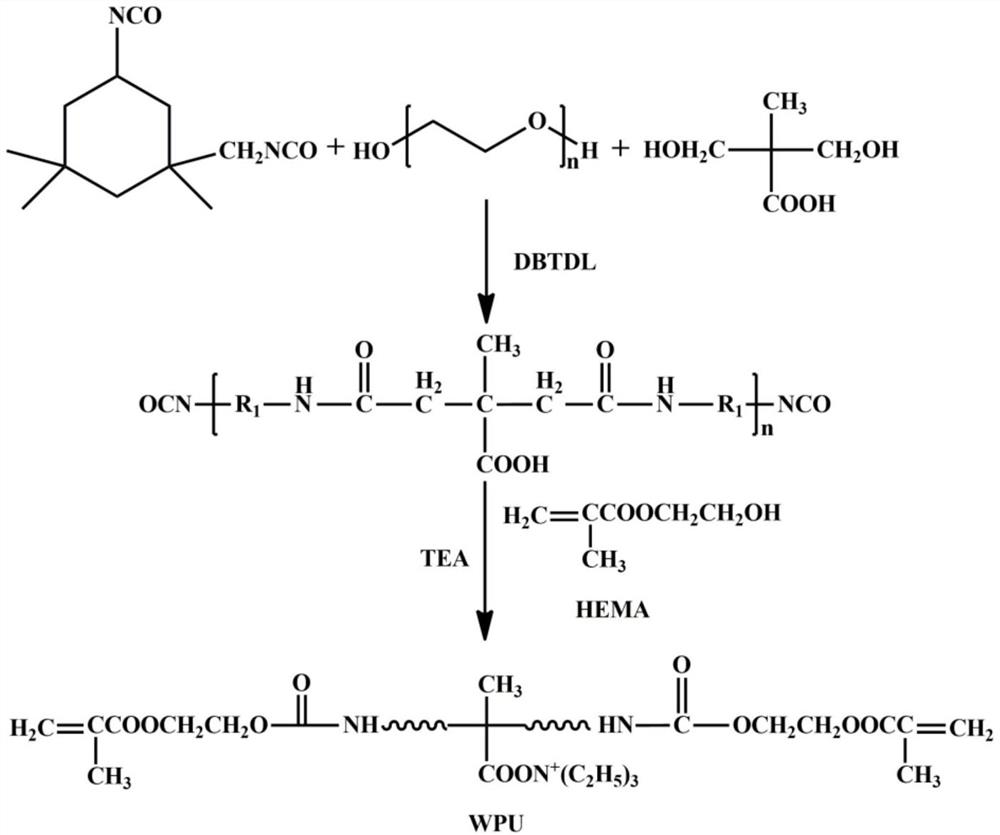

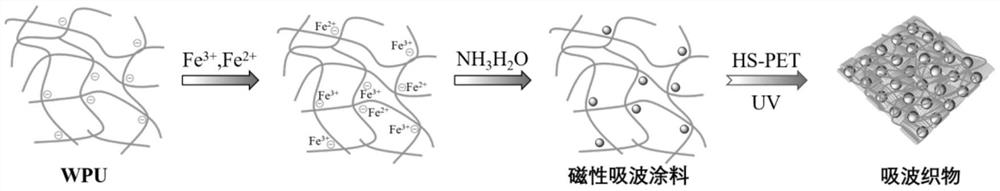

[0031] Preparation of Magnetic Fe Using Polyester Fabric as Substrate 3 o 4 / WPU / PET wave-absorbing fabric, the specific steps are as follows:

[0032] (1) Preparation of magnetic WPU absorbing coating

[0033] a. Take 14.63g of IPDI, 12g of PEG400, 50mg of DBTDL and 2.45g of DMPA in a 500mL four-neck flask, and react for 4 hours in an 80°C oil bath, nitrogen atmosphere, condensing reflux, and mechanical stirring;

[0034] b. Cool down to 70°C, add 3.66g end-capping agent HEMA, and continue to react for 3h;

[0035] c. Cool down to room temperature, add 1.64g neutralizing agent TEA to react for 45min, take it out, freeze-dry;

[0036] d. Take 1.21g NH 4 Fe(SO 4 ) 2 12H 2 O and 0.49g (NH 4 ) 2 FeSO 4 ·6H 2 O was dissolved in 100mL of distilled water, and an equal mass of it was added to the WPU prepared above, and emulsified under high-speed shear at 3000r / min for 20min;

[0037] e. Use 25wt% ammonia water to adjust the pH value of the emulsion to 10, and react for ...

Embodiment 2

[0043] Preparation of Magnetic Fe Using Polyester Fabric as Substrate 3 o 4 / WPU / PET wave-absorbing fabric, the specific steps are as follows:

[0044] (1) Preparation of magnetic WPU absorbing coating

[0045] a. Take 14.63g of IPDI, 12g of PEG400, 50mg of DBTDL and 2.45g of DMPA in a 500mL four-neck flask, and react for 4 hours in an 80°C oil bath, nitrogen atmosphere, condensing reflux, and mechanical stirring;

[0046] b. Cool down to 70°C, add 3.66g end-capping agent HEMA, and continue to react for 3h;

[0047] c. Cool down to room temperature, add 1.64g neutralizing agent TEA to react for 45min, take it out, freeze-dry;

[0048] d. Take 2.41g NH 4 Fe(SO 4 ) 2 12H 2 O and 0.98g (NH 4 ) 2 FeSO 4 ·6H 2 O was dissolved in 100mL of distilled water, and an equal mass of it was added to the WPU prepared above, and emulsified under high-speed shear at 3000r / min for 20min;

[0049] e. Use 25wt% ammonia water to adjust the pH value of the emulsion to 10, and react for ...

Embodiment 3

[0055] Preparation of Magnetic Fe Using Polyester Fabric as Substrate 3 o 4 / WPU / PET wave-absorbing fabric, the specific steps are as follows:

[0056] (1) Preparation of magnetic WPU absorbing coating

[0057] a. Take 14.63g of IPDI, 12g of PEG400, 50mg of DBTDL and 2.45g of DMPA in a 500mL four-neck flask, and react for 4 hours in an 80°C oil bath, nitrogen atmosphere, condensing reflux, and mechanical stirring;

[0058] b. Cool down to 70°C, add 3.66g end-capping agent HEMA, and continue to react for 3h;

[0059] c. Cool down to room temperature, add 1.64g neutralizing agent TEA to react for 45min, take it out, freeze-dry;

[0060] d. Take 4.82g NH 4 Fe(SO 4 ) 2 12H 2 O and 1.96g (NH 4 ) 2 FeSO 4 ·6H 2 O was dissolved in 100mL of distilled water, and an equal mass of it was added to the WPU prepared above, and emulsified under high-speed shear at 3000r / min for 20min;

[0061] e. Use 25wt% ammonia water to adjust the pH value of the emulsion to 10, and react for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com