An oil removal ship and method for recovering and cleaning oil slicks on the water surface by using magnetic powder

A technology of magnetic powder and oil slick on the water surface, which is applied in the field of oil removal ship and oil slick treatment, can solve the problems of unsatisfactory efficiency of oily wastewater, secondary pollution cost, long treatment time, etc., and achieve strong magnetic response and fast adsorption High reliability, high reliability and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

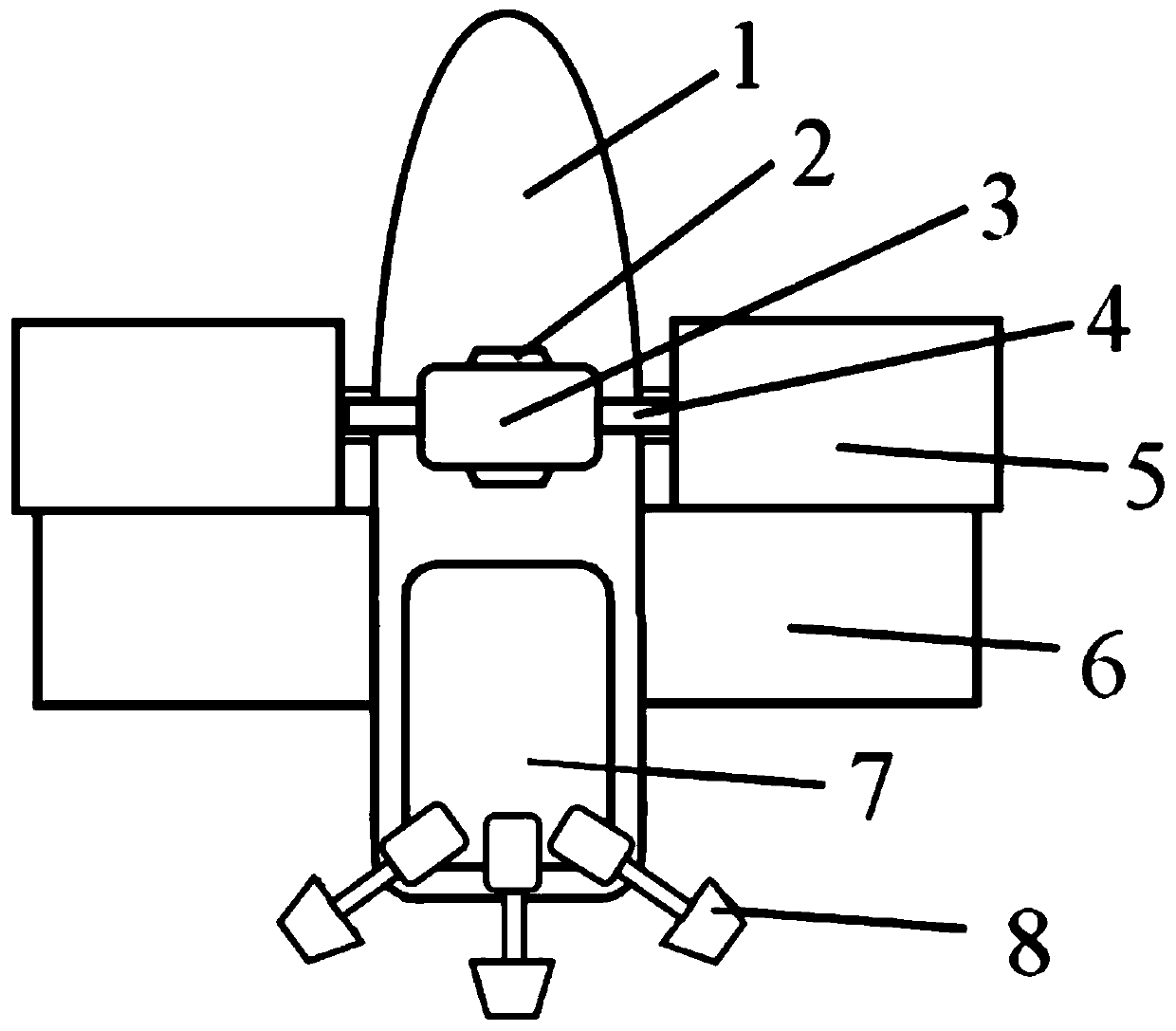

[0046] Use a deoiler with a total length of 8m, a molded width of 2.5m, a draft of 0.4m, a displacement of 3.5t, equipped with two 75hp Honda BF7 propellers, and a speed of 10~30km / h, and handle 1×10 4 m 2 The oil slick contaminates the water surface.

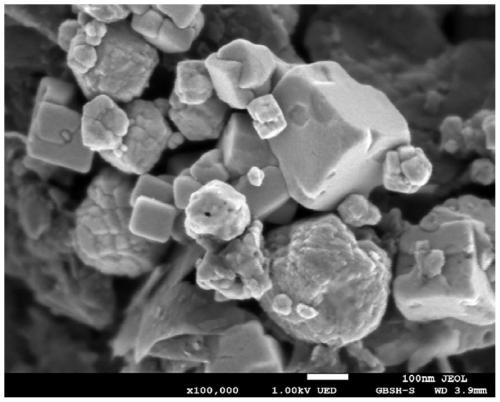

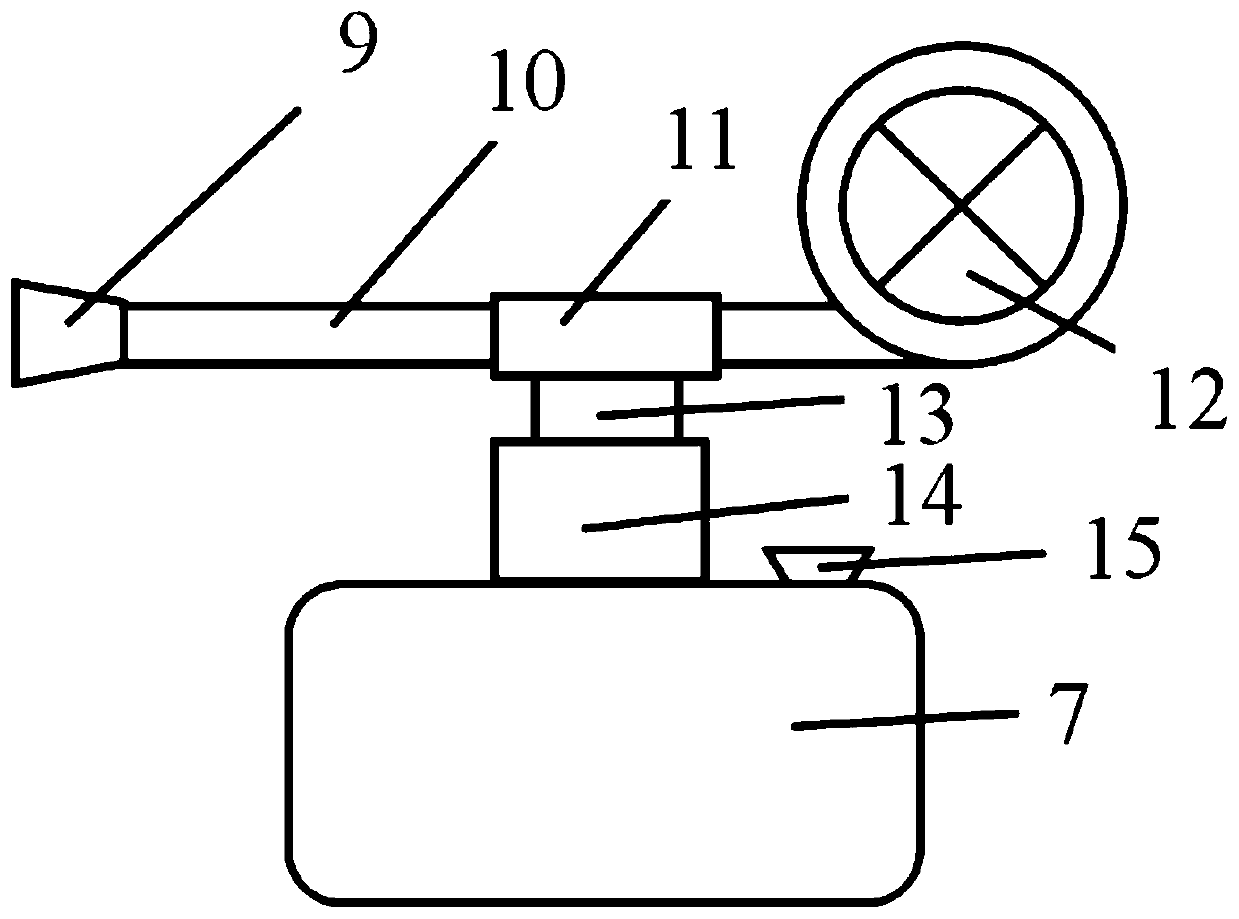

[0047] Preparation of 300 kg of Fe by hydrothermal method and high temperature carbonization 3 o 4 @C / Cu special magnetic powder, put the special magnetic powder into the powder storage box 7 of the oil removal ship; drive the oil removal ship to the edge of the oil slick polluted area, start the powder sprayer 8 on the three oil removal ships at the stern , adjust the powder spray rate of each powder sprayer 8 to be 30kg / h, the powder spray distance to be 5m, and the travel speed of the deoiler to be 10km / h. The area covered by the hourly oil spill is 9.63×10 4 m 2 ; When the deoiling ship travels to the end of the polluted area covered by the special magnetic powder sprayed by the powder sprayer 8, close the powder spray...

Embodiment 2

[0049] Use a deoiler with a total length of 8m, a molded width of 2.5m, a draft of 0.4m, a displacement of 3.5t, equipped with two 75hp Honda BF7 propellers, and a speed of 10~30km / h, and handle 1×10 4 m 2 The oil slick contaminates the water surface.

[0050] First, 300 kg of Fe was prepared by hydrothermal method and high-temperature carbonization method 3 o 4 @C / Cu special magnetic powder, put the special magnetic powder into the powder storage box 7 of the oil removal ship;

[0051] Drive the oil removal ship to the edge of the oil slick pollution area, start the duster 8 on the 3 oil removal ships at the stern, adjust the dusting rate of each duster 8 to be 100kg / h, and the dusting distance is 10m. The driving speed is 30km / h. When the oil removal ship starts, the special magnetic powder sprayed by the powder sprayer 8 covers an area of 35.87×10 4 m 2 ; When the deoiling ship travels to the end of the polluted area covered by the special magnetic powder sprayed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com