A multi-reinforcement integrated layout device suitable for 3D printed concrete structures

A concrete structure and 3D printing technology, applied in truss structure, building structure, building material processing, etc., can solve the problems of limited reinforcing effect of a single steel wire rope, large size of printing head, etc., to achieve construction automation and low cost , the effect of increasing the degree of liberalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

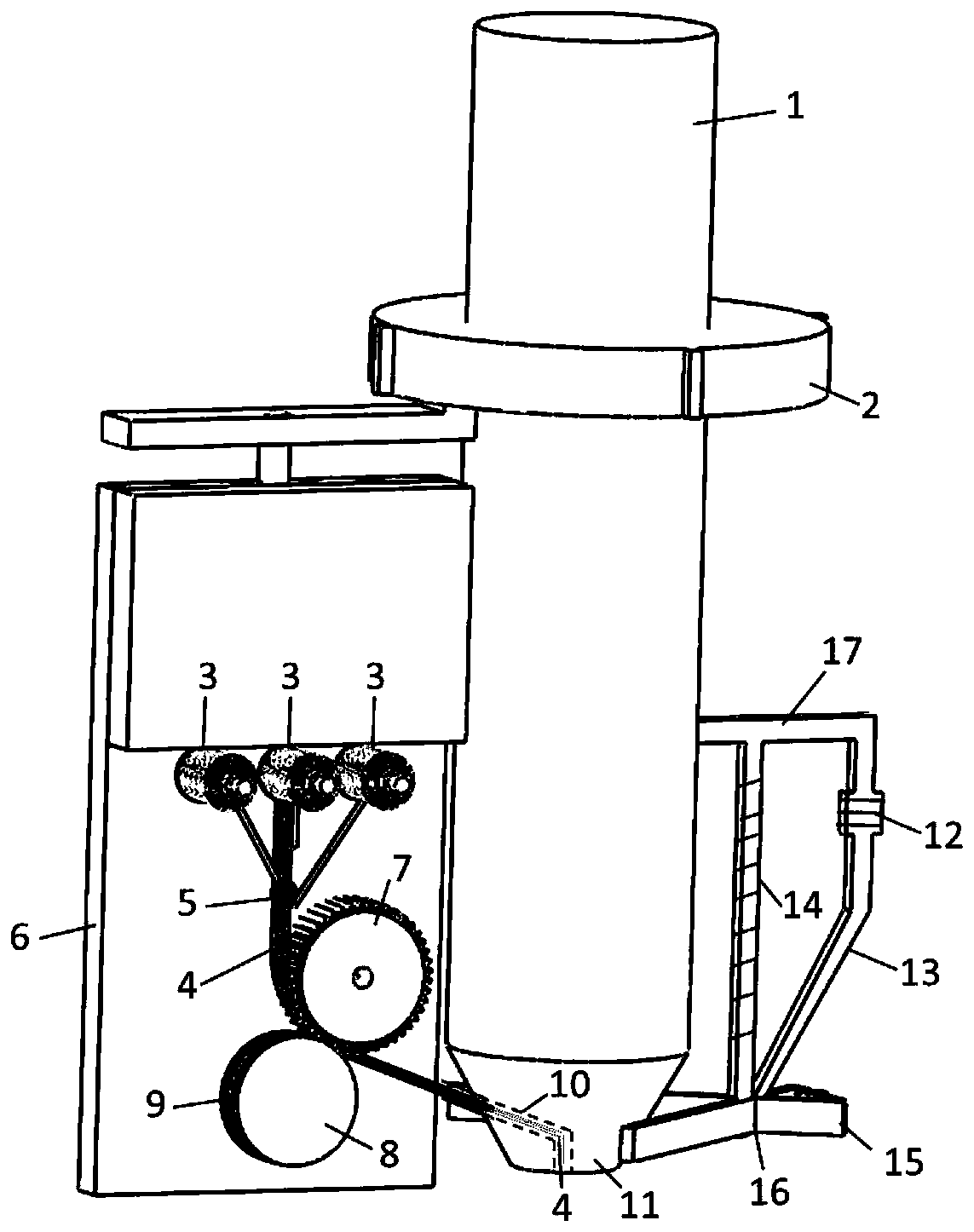

Embodiment 1

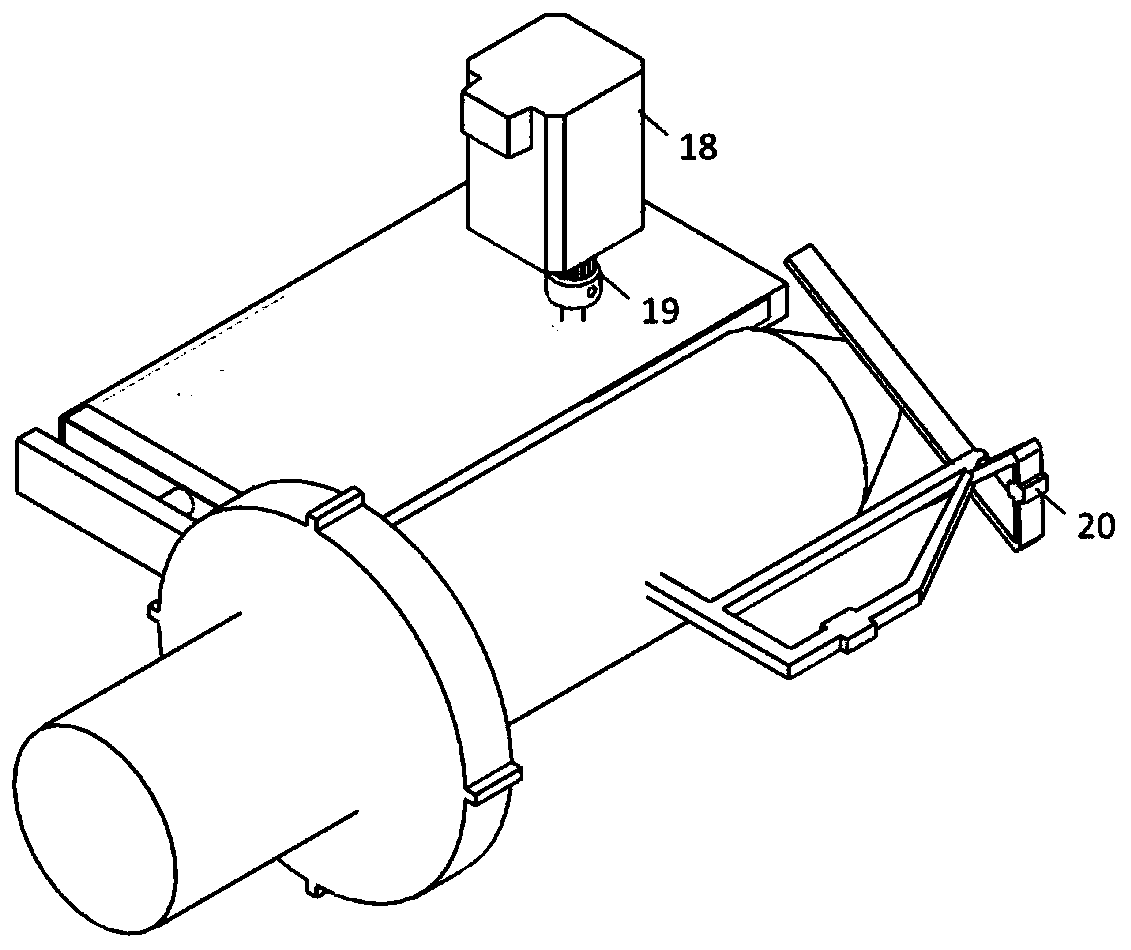

[0030] In this embodiment, three wire rope spools 3 are selected, and the structure of the wire rope wound on each wire rope spool is 7*19, with a diameter of 1.2mm. The wire rope with this structure is flexible, which is beneficial to the free layout in the 3D printing process. Wire rope 4 enters the tendon feeding unit through wire rope spool 3 and guide wheel 5, and stepper motor 18 drives driving gear 7 to rotate through shaft coupling 19, and the rotation of stepper motor 18 is controlled by the control system. The driving gear 7 is in close contact with the driven pulley 8, and the driving gear 7 drives the driven pulley 8 to rotate to provide the power to send the tendons downward. The peripheral side of the driven pulley 8 is evenly provided with multi-circumferential grooves 9, which are used as conveying channels for steel wire ropes during the tendon feeding process. Under the action of the driving gear 7 and the driven pulley 8, it is sent into the concrete printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com