Series of rocket thrust chambers with direct-current heads and cooling discharge partition plates

A technology of rocket thrust and thrust chamber, which is applied in the direction of rocket engine devices, jet propulsion devices, machines/engines, etc., and can solve problems such as propellants not containing liquid oxygen methane, partitions with different partition areas, and partitions with end parts, etc. problem, to achieve the effect of suppressing high-frequency unstable combustion, good internal cooling effect, and reliable cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

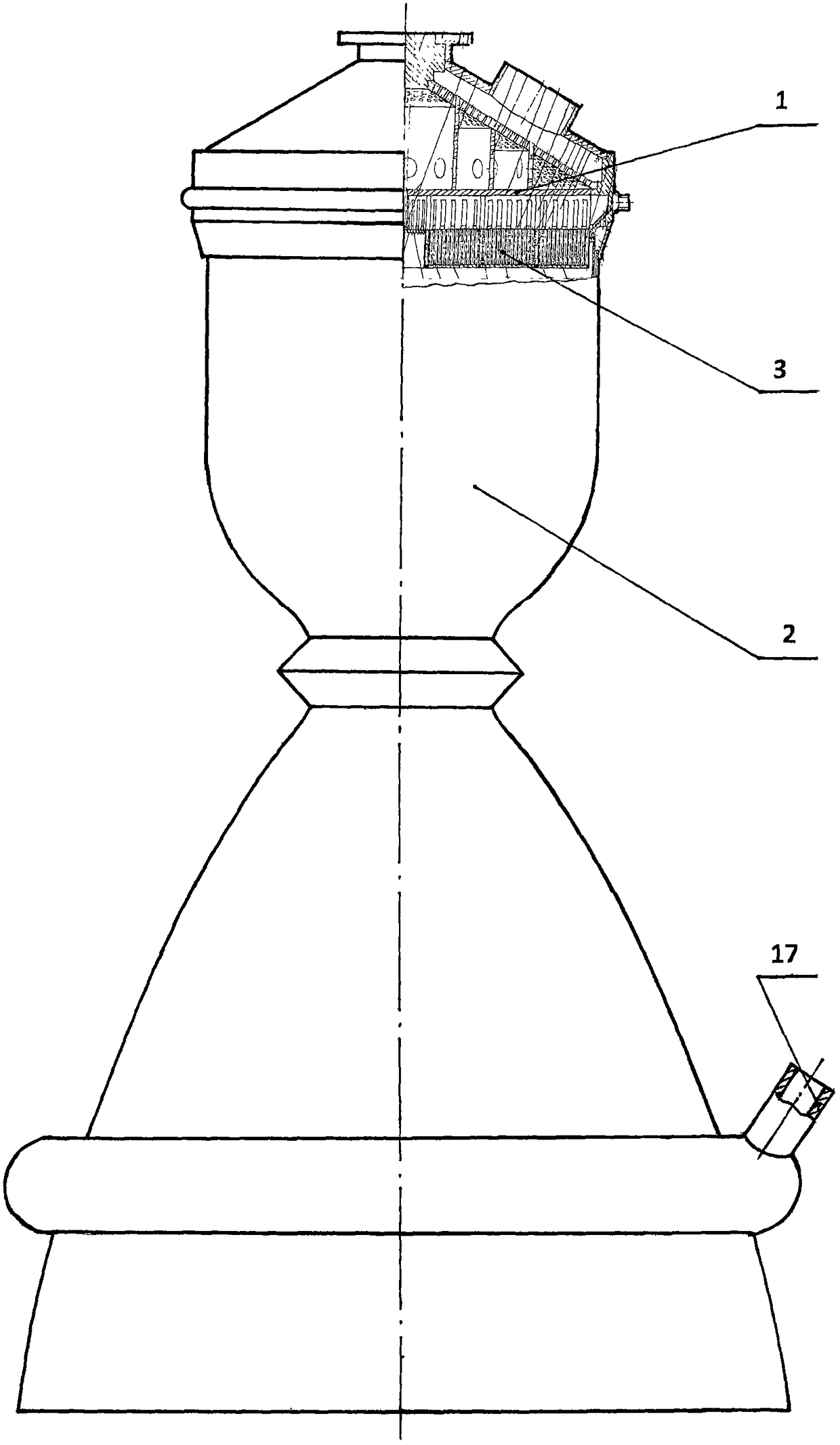

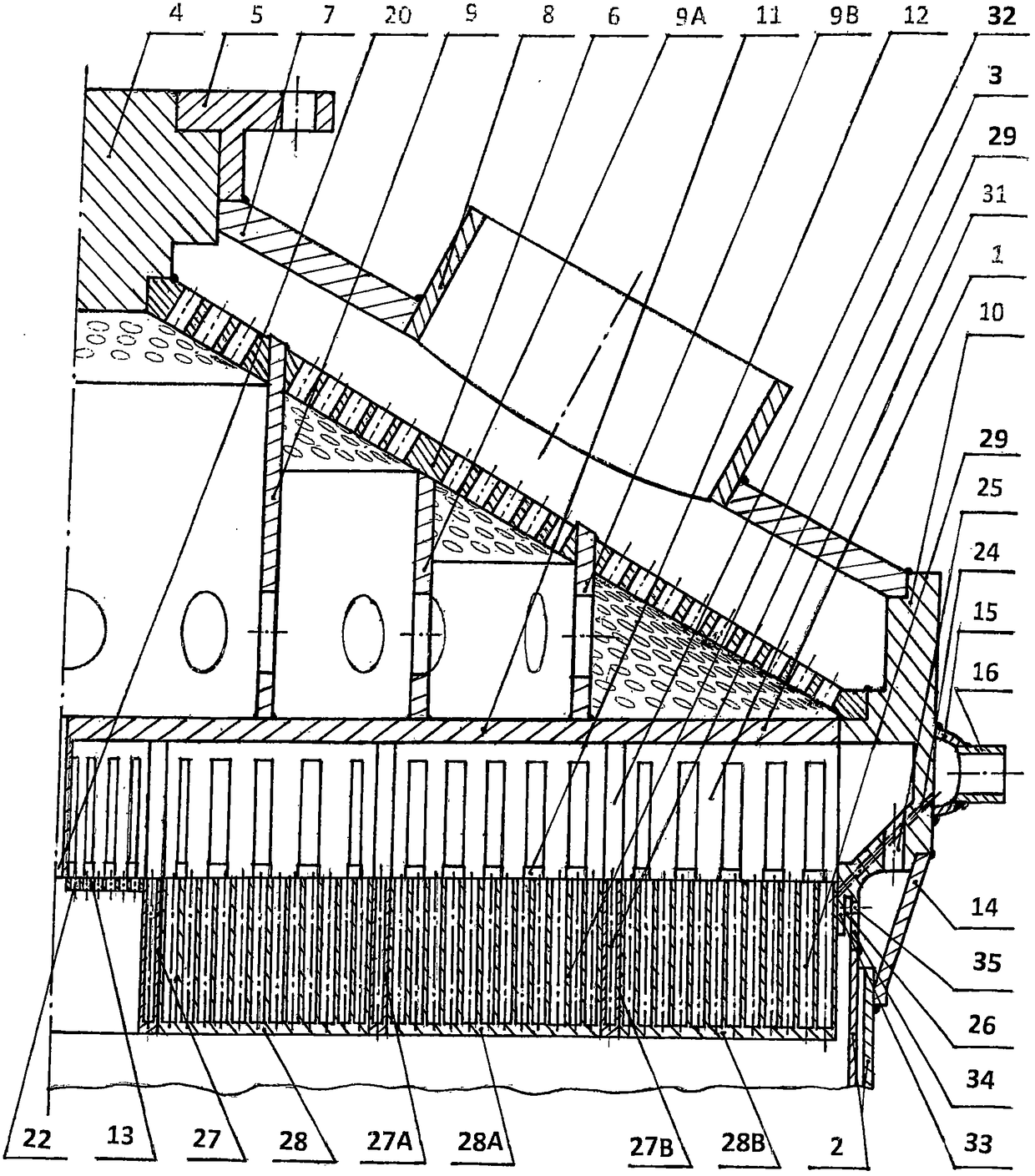

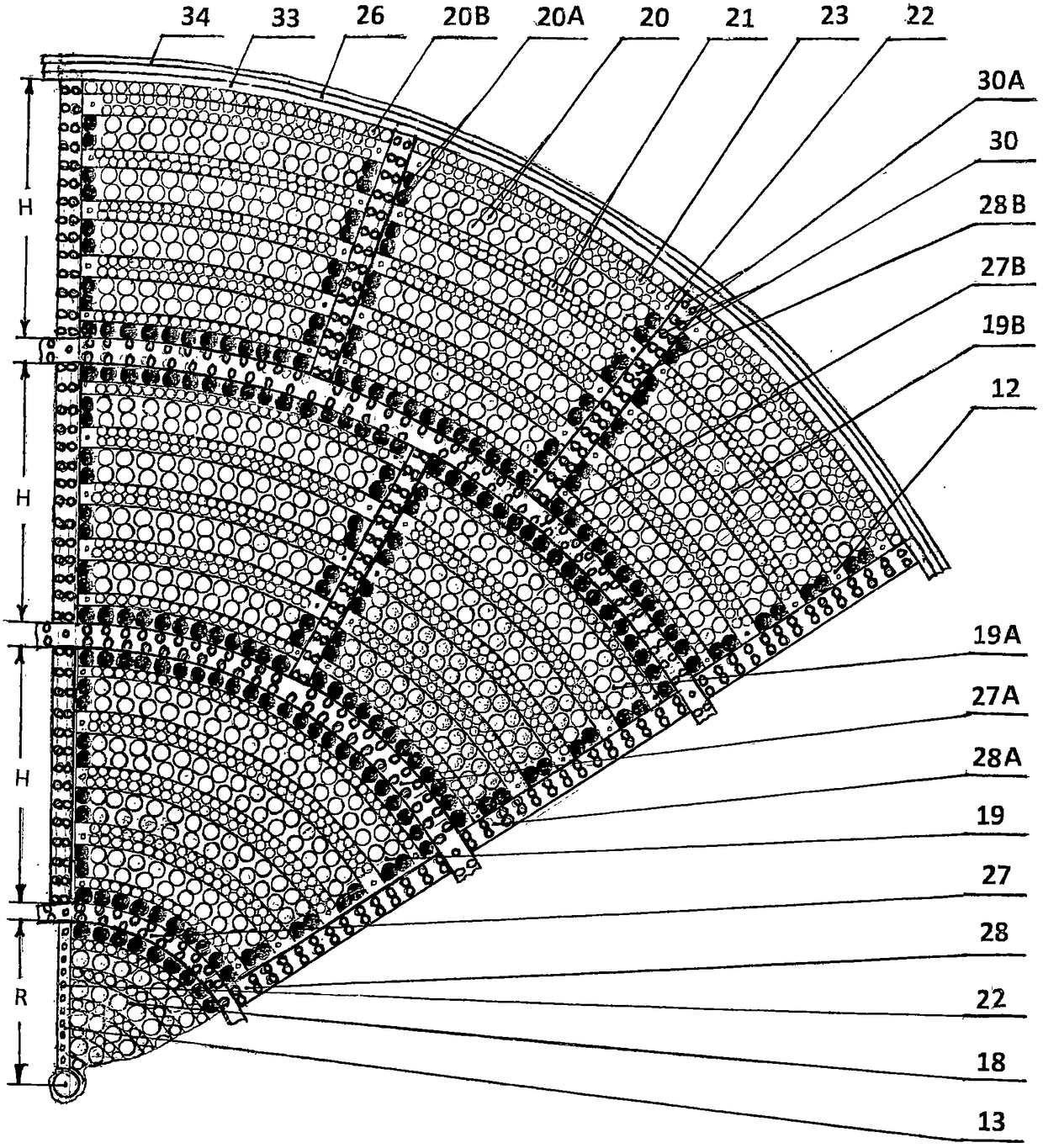

[0035] Figure 1 to Figure 9 It is a preferred embodiment of the series rocket thrust chambers of the present invention with straight-through heads and cooling discharge partitions.

[0036] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a basic rocket thrust chamber is composed of a head 1, a body 2 and a partition 3 and welded as a whole. The connecting parts of the head 1 and these three parts include a bearing seat 4, a flange 5, a porous inner cone shell 6, an outer cone shell 7, a turbine exhaust introduction pipe 8, a first bearing connector 9, a second bearing Force connector 9A, third load-bearing connector 9B, connection collection ring 10, injector plate 11, injection arc section plate group 12, injection radial plate 13, head-body connecting plate 14, ignition fuel collector 15 and ignition fuel enters tube 16. The head 1 is a high-strength head 1A1 that connects the thick injector disk 11 with the porous inner cone shell 6 through various l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com