LED aircraft observation lamp with automatic target correcting function

A technology of LED modules and functions, applied in the field of LED lighting, can solve problems such as waste of onboard energy, poor anti-vibration performance, and visual fatigue, and achieve the effects of simple structure, reduced maintenance costs, and easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

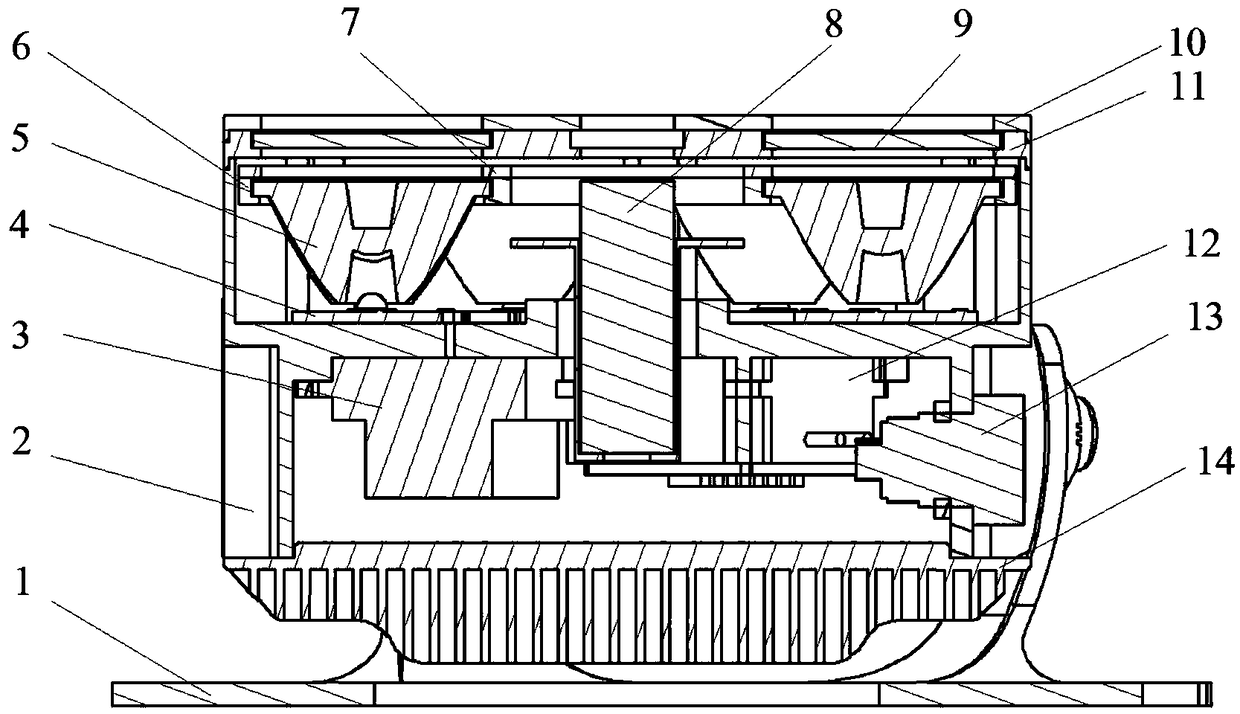

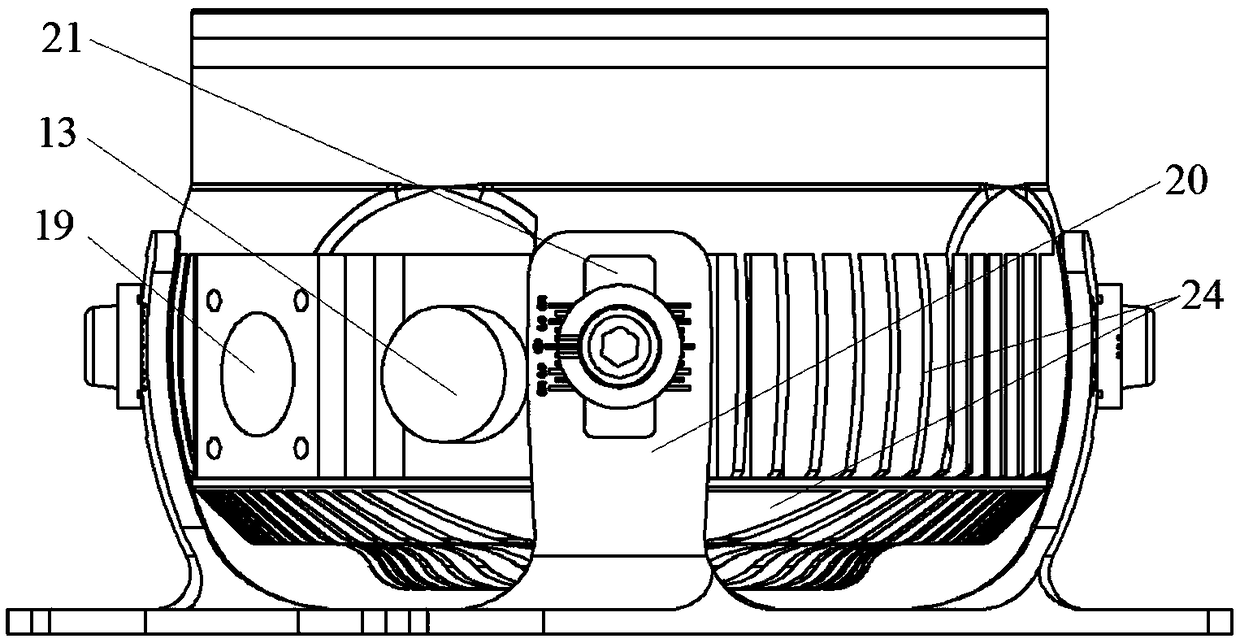

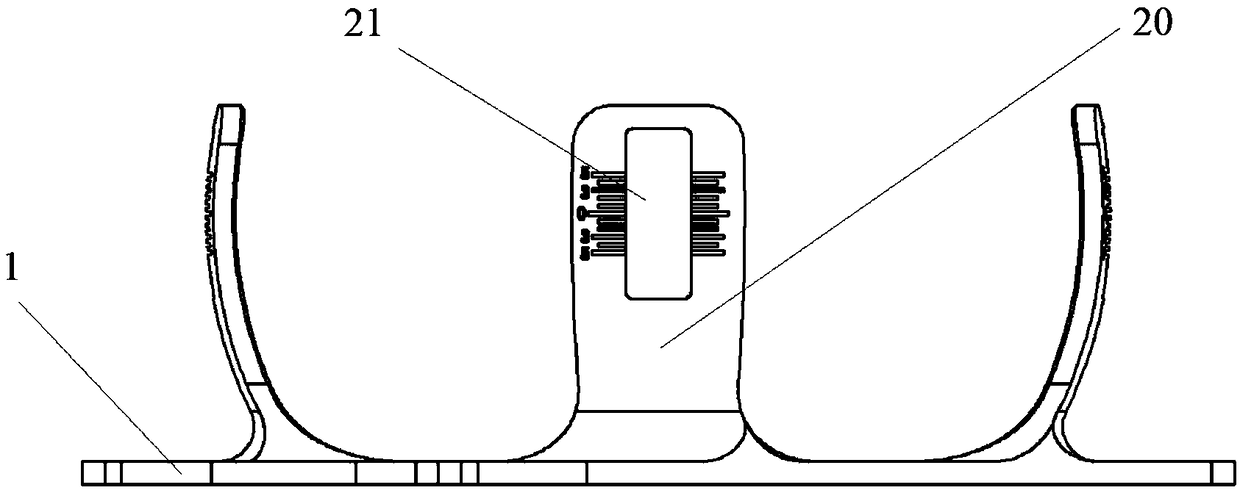

[0032] like Figure 1 to Figure 6 As shown, a LED aircraft observation light with self-calibration target function includes a fixed bracket 1 and a main body shell 2 with a bowl-shaped structure. The main body shell 2 is rotatably connected to the fixed bracket 1. There is a laser mounting table 15, a drive mounting table 17 and a filter mounting table 18, an LED mounting table 16 is arranged around the laser mounting table 15, a laser 8 is installed on the laser mounting table 15, and a fixed connection is made on the driving mounting table 17. The drive module 3, the filter module 12 is installed on the filter installation platform 18, the LED module 4 is installed on the LED installation platform 16, the lower end of the LED module 4 is electrically connected to the driver module 3 and a TIR lens 5 is arranged above it, so The top of the TIR lens 5 is provided with a slide 9, and the slide 9 is fixed between the front cover pressing plate 10 and the front cover 11, the filt...

Embodiment 2

[0035] like Figure 1 to Figure 6As shown, a LED aircraft observation light with self-calibration target function includes a fixed bracket 1 and a main body shell 2 with a bowl-shaped structure. The main body shell 2 is rotatably connected to the fixed bracket 1. There is a laser mounting table 15, a drive mounting table 17 and a filter mounting table 18, an LED mounting table 16 is arranged around the laser mounting table 15, a laser 8 is installed on the laser mounting table 15, and a fixed connection is made on the driving mounting table 17. The drive module 3, the filter module 12 is installed on the filter installation platform 18, the LED module 4 is installed on the LED installation platform 16, the lower end of the LED module 4 is electrically connected to the driver module 3 and a TIR lens 5 is arranged above it, so The top of the TIR lens 5 is provided with a slide 9, and the slide 9 is fixed between the front cover pressing plate 10 and the front cover 11, the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com