Jet self-cleaning type membrane assembly

A membrane module and self-cleaning technology, which is applied in membrane technology, semi-permeable membrane separation, water treatment parameter control, etc., can solve problems such as inability to grow microorganisms, membrane material pollution and blockage, sewage isolation, etc., and achieve strong emergency treatment capabilities, The effect of wide range and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

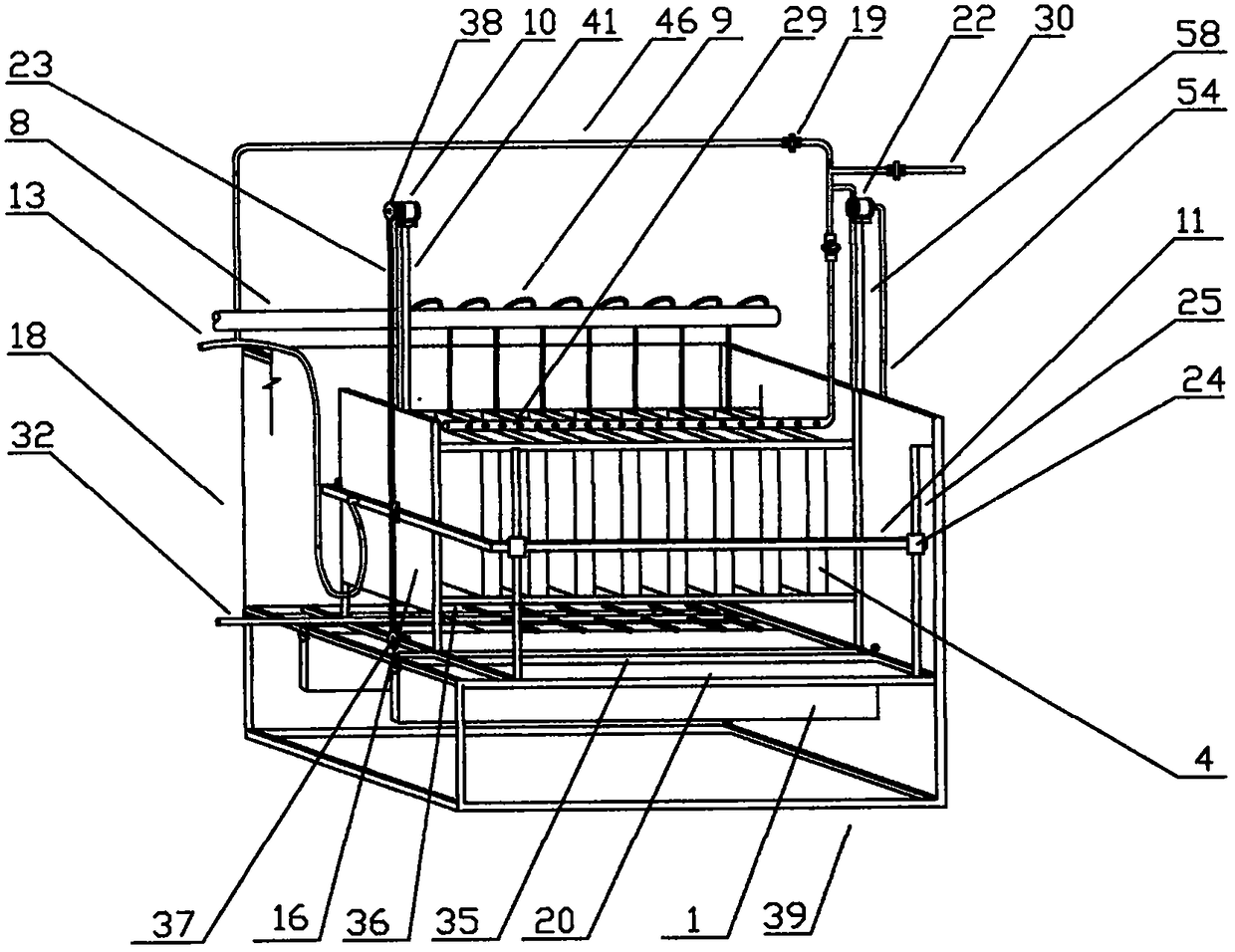

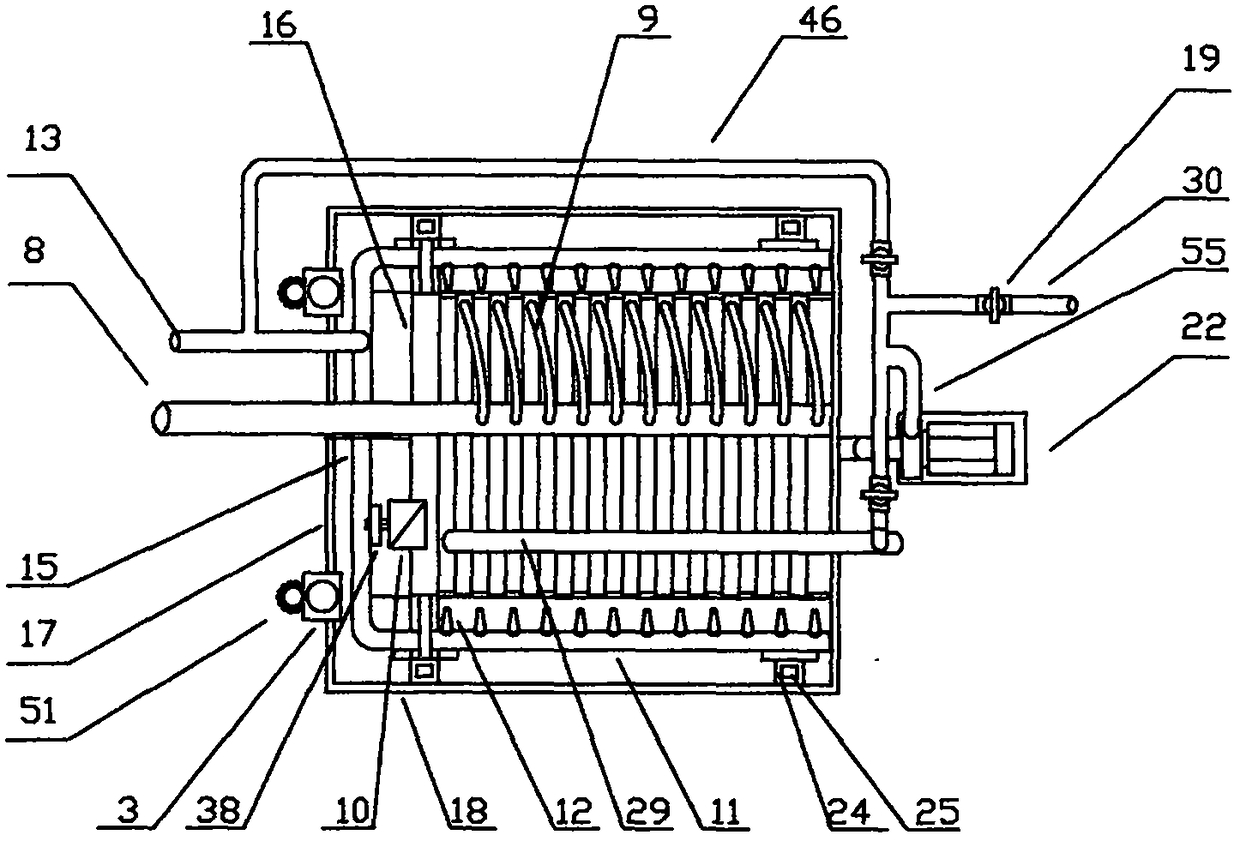

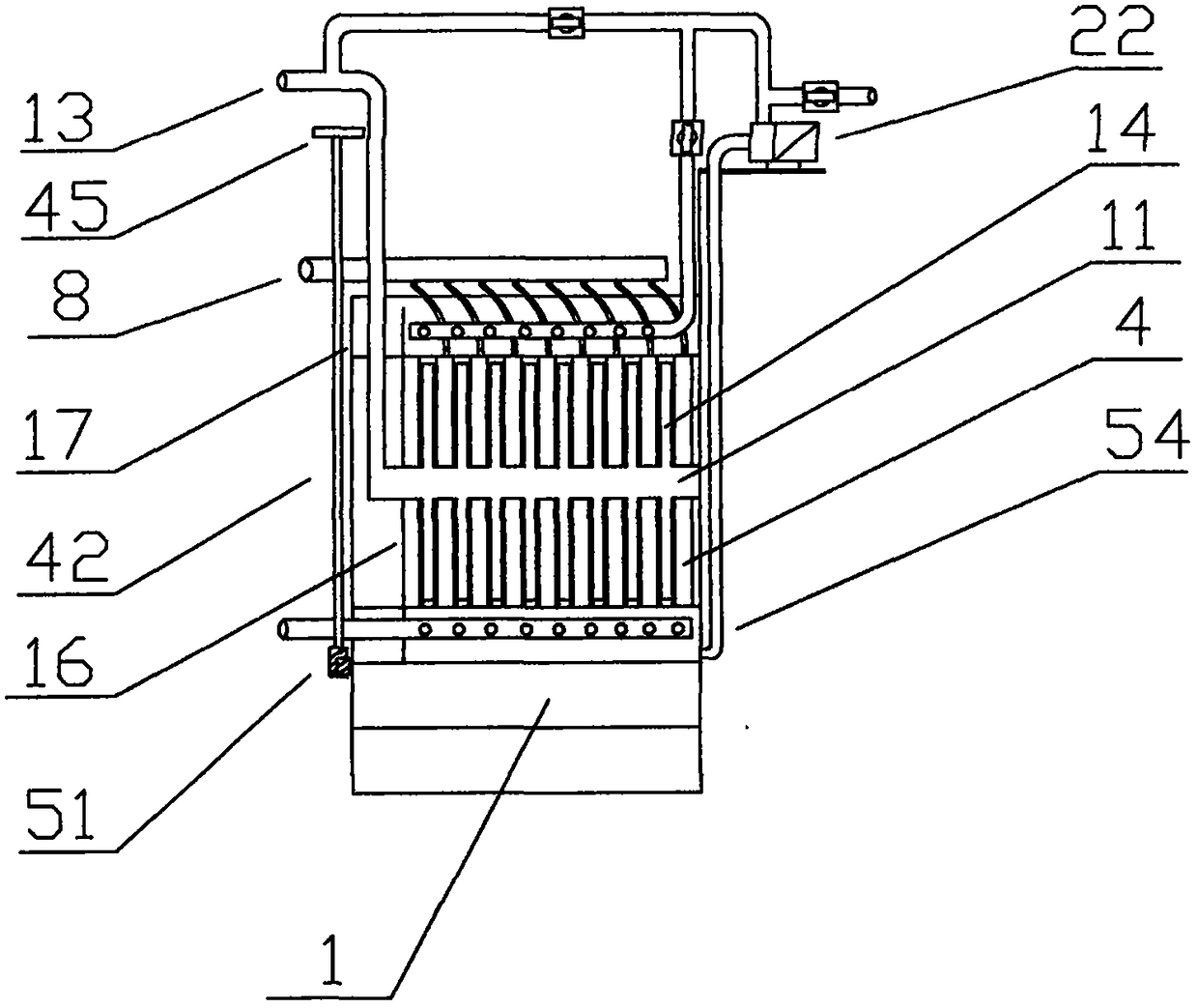

[0041] The structure and characteristics of the jet self-cleaning membrane module of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0042] Jet self-cleaning membrane components, such as figure 1 , figure 2 , image 3 Shown: including frame structure, fixed cleaning system or mobile cleaning system, lower gate 1, vertical gate 2, aeration pipe 32, circulation system, membrane material and water production pipe 8; wherein the frame structure is composed of an inner frame and an outer frame, and the outer The frame includes a bottom plate 39, an outer top plate 17, a side vertical plate 18, and a vertical gate 2; the bottom plate 39 is rectangular and arranged at the bottom, one side of the bottom plate is fixedly connected with the bottom of the outer top plate 17 of the head, and the opposite side is connected with the outer top plate 17 of the tail portion. The lower part of the roof is fixedly connected; the edges ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com