Method for Anti-hydrogen Fluoride Corrosion of Glass in Aluminum Electrolysis Industry

A technology of aluminum electrolysis and hydrogen fluoride, which is applied to devices and coatings for coating liquid on the surface, which can solve the problem of damage to glass parts of aluminum electrolysis multifunctional cranes, reduction of working reliability of aluminum electrolysis cranes, and failure of equipment to work normally, etc. problems, to achieve the effect of increasing the coating accuracy, easy control, and reducing the adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

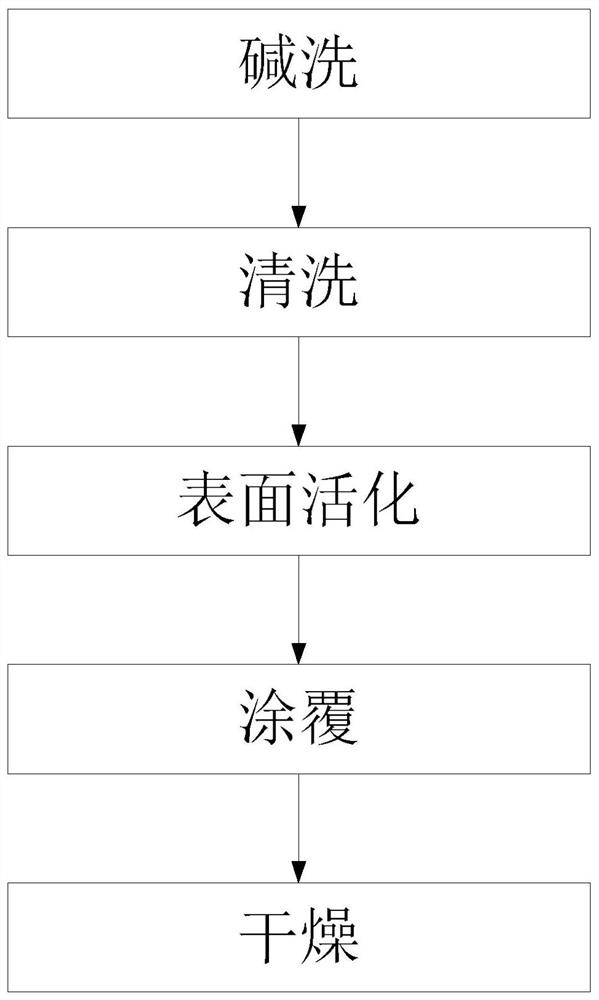

[0024] Such as figure 1 As shown, a method for preventing hydrogen fluoride corrosion of glass applied in the aluminum electrolysis industry includes the steps of alkali washing, cleaning, surface activation, coating and drying of the glass in sequence; alkali washing, cleaning, surface activation and drying are conventional techniques, I won't repeat them here. Wherein said coating is carried out according to the following steps:

[0025] Step 1. Establish a glass thickness database; the glass thickness database includes temperature value, spray gun end pressure value, spraying time and thickness value of the glass after coating; the temperature value, spraying time, spray gun end pressure value and coated glass The detection of the thickness value is an existing mature technology, and will not be repeated here.

[0026] Step 2: Install n heating elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com