Electric welding rod for high-manganese austenite low-temperature steel

A low-temperature steel and electrode technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of poor microstructure stability and insufficient low-temperature toughness of high-manganese electrodes, and avoid changes in structure and performance. Good toughness matching, good composition matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the enumerated examples are not intended as limitations of the present invention.

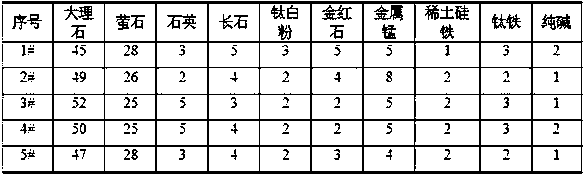

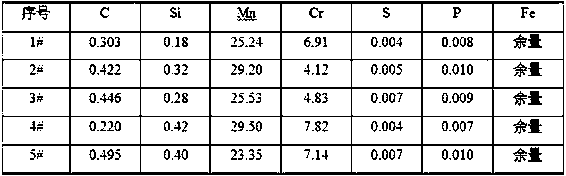

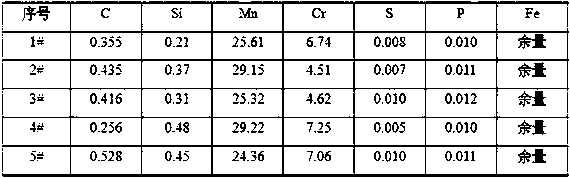

[0010] The electrode of the invention is composed of a high manganese welding core and a coating coated on the surface of the high manganese welding core, and mainly adopts transitional alloy elements of the welding core. Based on the total weight of the welding core, the chemical composition of the welding core is (weight ratio): C: 0.20-0.50%, Si: 0.15-0.50%, Mn: 23.0-30.0%, Cr: 4.0-8.0%, S≤ 0.008, P≤0.010%, the rest is Fe and unavoidable impurities. There are no special requirements for the production of welding cores, but due to the strong work hardening of high manganese steel, attention should be paid to increasing the number of annealing during the drawing and reducing process. Refer to the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com