An arc material additive device and method with adjustable feeding direction

An arc and feeding technology, applied in the field of additive manufacturing, can solve problems such as increasing the complexity of forming, control system, and restricting promotion, so as to improve forming stability and organizational uniformity, improve stability and consistency, and improve mechanics. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

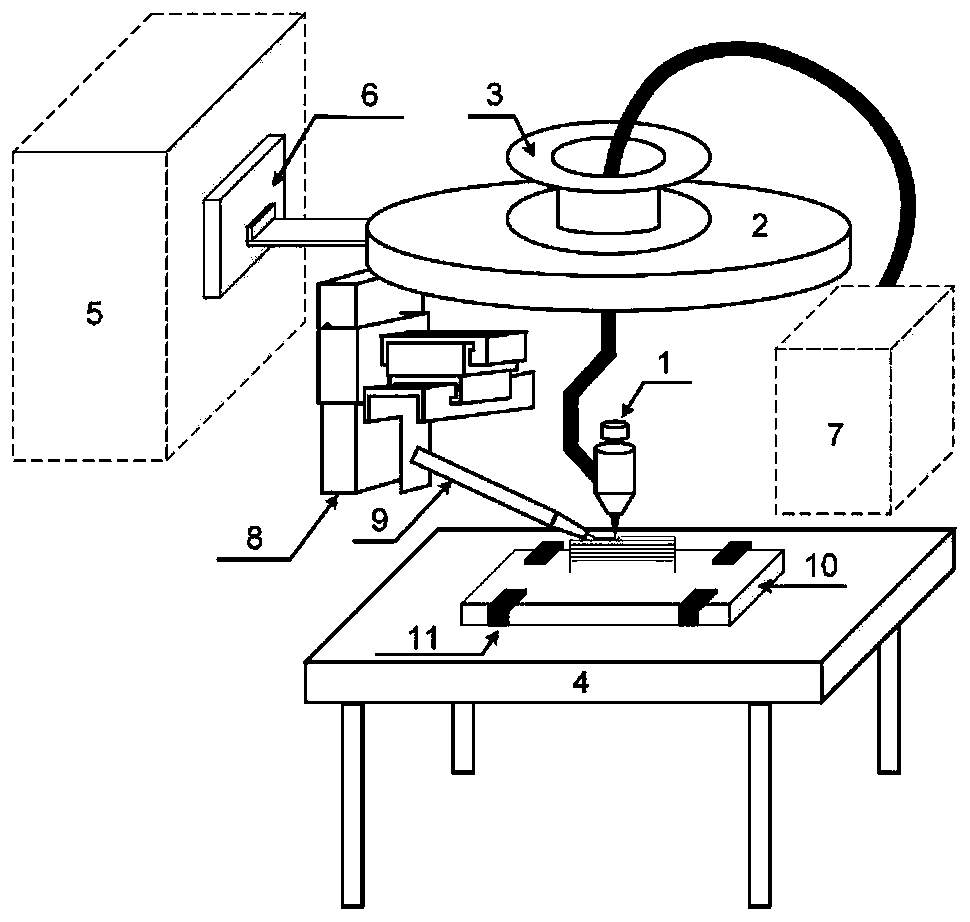

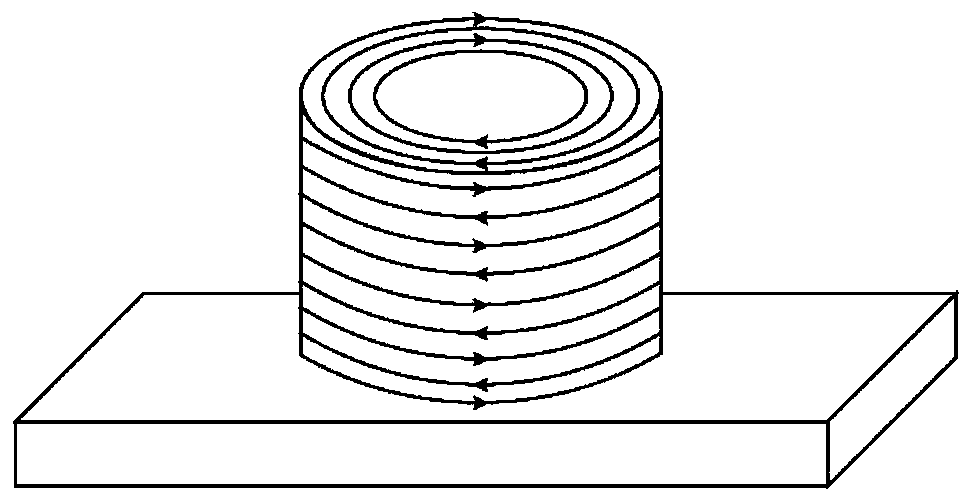

[0048] In this embodiment, the present invention is described by taking a stainless steel cylinder as an example, as image 3 As shown, the stainless steel cylinder is 120mm high, 60mm wall thickness, and 50mm inner diameter. It is composed of 40 deposited layers, each layer is 3mm in height, and each layer is composed of 10 filler metals. Additive process parameters: The welding wire adopts ER316L austenitic stainless steel welding wire with a diameter of 1.6mm, adopts DC positive connection, arc current is 147A, arc voltage is 14.2V, wire feeding speed is 6m / min, deposition speed is 0.6m / min; traveling mechanism 5 Drive the circular guide rail 2 and the welding torch 1 below the circular guide rail 2 to make a circular motion to realize the deposition of the circular trajectory, the rotation speed is 6r / min; the distance between the tungsten electrode and the substrate is 8mm, and the distance between the tungsten electrode and the filling material is 5mm; The three-dimensio...

Embodiment 2

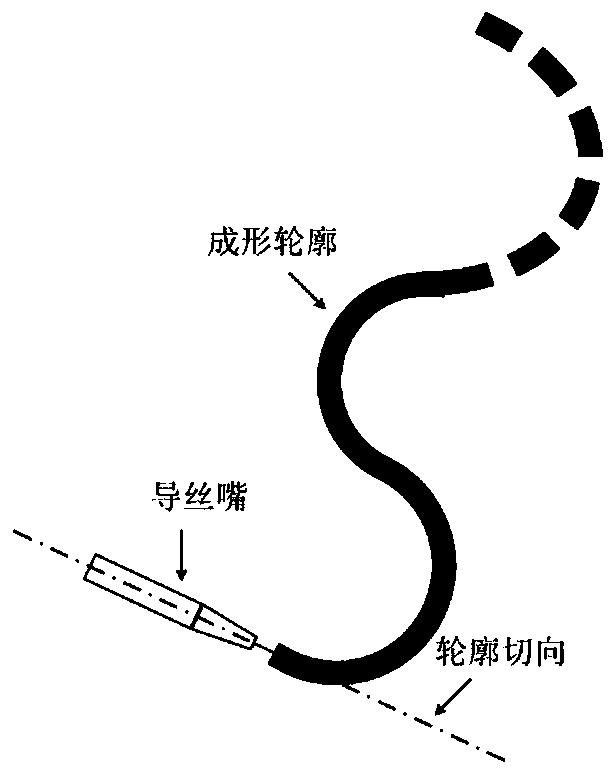

[0058] This embodiment takes the titanium alloy curved wall as an example to illustrate the present invention, as Figure 5 As shown, the titanium alloy curved wall is 65mm high, composed of two semicircles with a radius of 50mm, and a wall thickness of 10mm. It is composed of 50 deposited layers, each layer is 1.3mm in height, and each layer is composed of a filler metal. Additive process parameters: the welding wire adopts TC with a diameter of 1.2mm 4 Titanium alloy welding wire adopts direct current connection, arc current is 160A, arc voltage is 21V, wire feeding speed is 4m / min, deposition speed is 0.3m / min; the distance between tungsten electrode and substrate is 5mm, and the distance between tungsten electrode and filling material The three-dimensional adjustment mechanism rotates at a small angle under the control of the computer to keep the welding wire alternately reciprocating scanning along the tangential direction of the deposition path. Argon is used as the arc ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com