Warm mixing agent suitable for high-viscosity asphalt and preparation method thereof

A technology of warm mixing agent and asphalt, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems that it is difficult to learn from research results, and achieve the effect of improving the high temperature softening point and using simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A warm mixing agent suitable for high-viscosity asphalt, comprising the following substances in parts by mass:

[0045] Propylene glycol monostearate 5 parts

[0046] 25 parts octadecane

[0047] Polyethylene wax 1 part

[0048] Castor oil 40 parts,

[0049] The warm mixing agent is mainly prepared by the following steps:

[0050] Step 1, the castor oil of proportioning amount is dehydrated at 100 DEG C;

[0051] Step 2, mixing the propylene glycol monostearate, crystal wax, polyethylene oligomer and dehydrated compatibilizer in a proportioning amount at 140°C in a stirrer with a heating function according to the preparation ratio;

[0052] Step 3: Blend, extrude, granulate and cool the homogeneously mixed substance in Step 2 in a screw extruder at a temperature of 110°C.

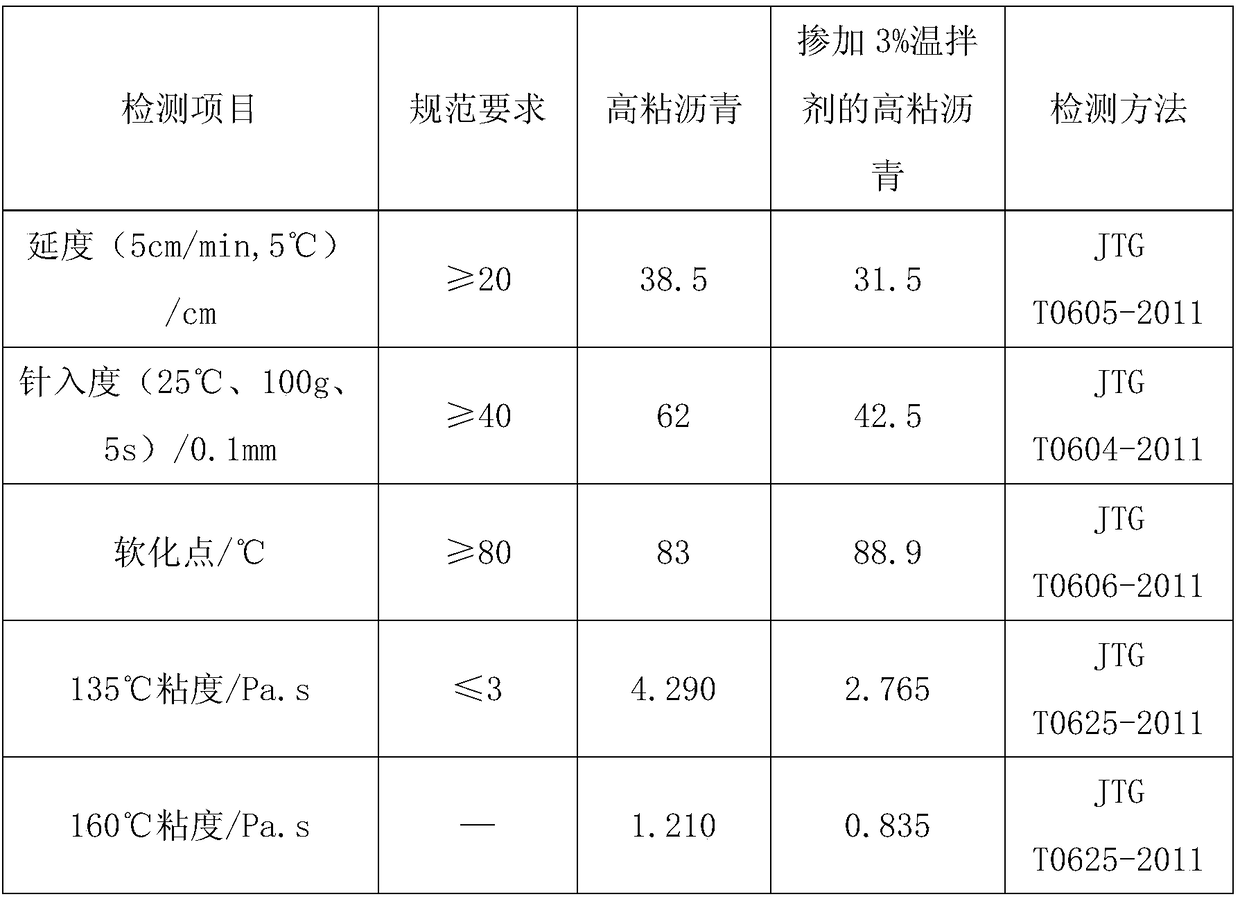

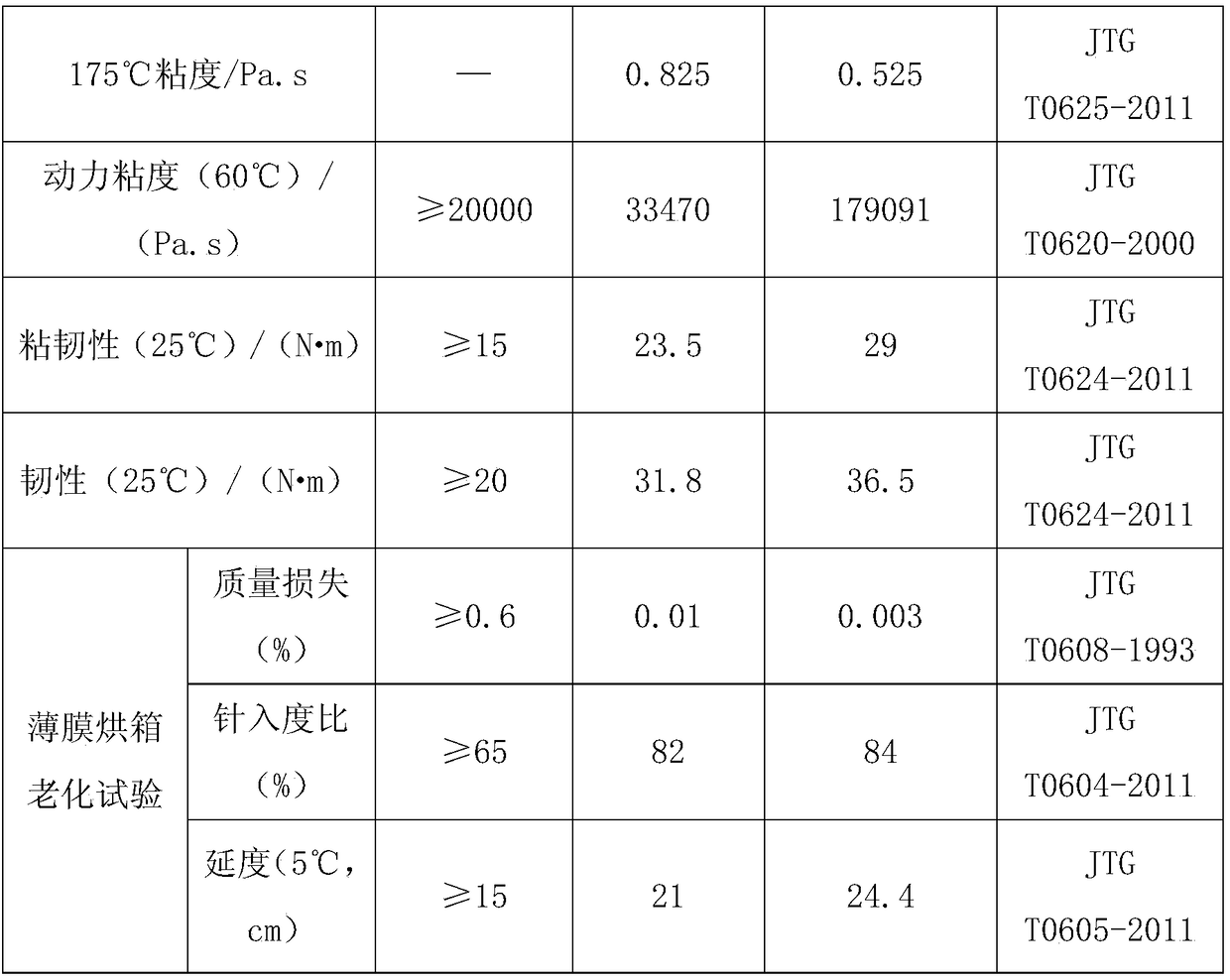

[0053] The warm mix agent that table 1 embodiment 1 makes is to the performance influence of high-viscosity asphalt

[0054]

[0055]

[0056] The warm mixing agent that table 2 embodimen...

Embodiment 2

[0059] A warm mixing agent suitable for high-viscosity asphalt, comprising the following substances in parts by mass:

[0060] 1 part propylene glycol laurate

[0061] 29 parts of glyceryl methacrylate

[0062] 1-heptene 1 part

[0063] Amide modified polyethylene wax 25 parts

[0064] 0.5 parts of furfural oil

[0065] 0.5 part of phthalic acid diester,

[0066] The warm mixing agent is mainly prepared by the following steps:

[0067] Step 1, dehydrating the compatibilizer in a proportioned amount at 125°C;

[0068] Step 2. Prepare propylene glycol laurate, crystalline wax, polyethylene oligomer and dehydrated compatibilizer (furfural oil and phthalate diester) in a stirrer with heating function at 140° C. The proportion is mixed evenly;

[0069] Step 3: Blend, extrude, granulate and cool the homogeneously mixed substance in Step 2 in a screw extruder at a temperature of 80°C.

[0070] The warm mix agent that table 3 embodiment 2 makes is to the performance influence of...

Embodiment 3

[0076] A warm mixing agent suitable for high-viscosity asphalt, comprising the following substances in parts by mass:

[0077] Propylene glycol monostearate 2 parts

[0078] Propylene glycol laurate 7 parts

[0079] 1 part glyceryl methacrylate

[0080] 7.5 parts of octadecane

[0081] 1-heptene 7.5 parts

[0082] 5 parts of polytetrafluoroethylene modified polyethylene wax

[0083] High density oxidation modified polyethylene wax 10 parts

[0084] 3 parts castor oil

[0085] 6 parts furfural oil

[0086] 1 part phthalate diester,

[0087] The warm mixing agent is mainly prepared by the following steps:

[0088] Step 1, dehydrating the compatibilizers in proportion at 115°C;

[0089] Step 2, mix the proportioned amount of surfactant, crystal wax, polyethylene oligomer and dehydrated compatibilizer in a stirrer with heating function at 140°C according to the preparation ratio;

[0090] Step 3: Blending, extruding, granulating and cooling the homogeneously mixed substa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com