Continuous electrochemical dissolving method for rhodium powder

An electrochemical and rhodium powder technology, applied in the field of dissolving rhodium powder, can solve the problems of reduced purity of rhodium trichloride, complex process, low yield of rhodium, etc., and achieve the effect of simplified operation, high product purity, and continuous feeding and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

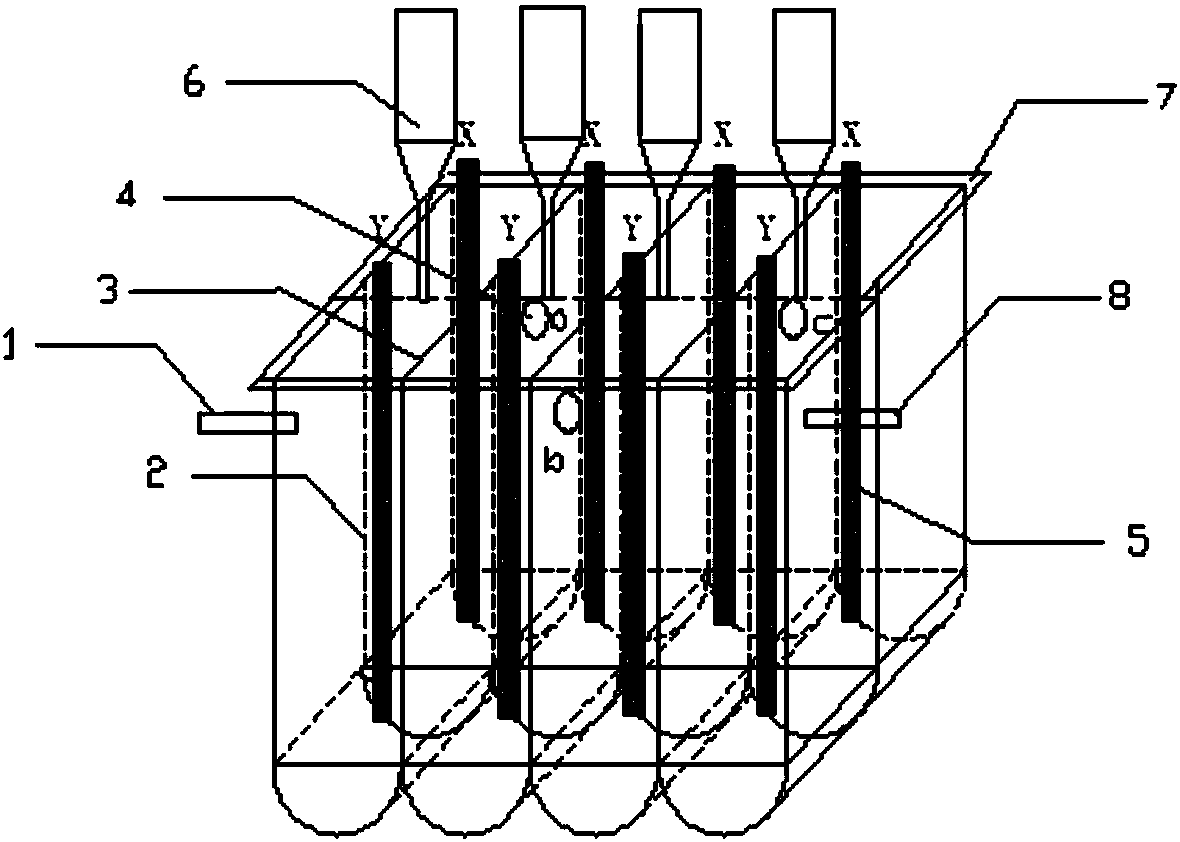

[0057] (1) Set up the electrolytic cell. The electrolytic cell has three groups of cells and six electrode chambers. The upper cross section of the cell body is rectangular in size 150mm×50mm and 300mm in height; the bottom of the two electrode chambers of the same cell body is a semicircle In the same way, there is a gap of 20mm from the top of the second partition; the overflow hole is opened at a position 50mm from the top, with a diameter of 10mm; a cylindrical graphite electrode with a spectral grade of Φ12mm and a length of 300mm is selected, a total of 12, fixed on the top cover, X, The distance between the Y electrodes is 100mm.

[0058] (2) 1200 grams of rhodium powder with a purity of 99.95% are evenly added to the bottom of the electrolytic cell, and the superior grade pure hydrochloric acid of 8mol / l is added from the feeding port until all tank bodies are filled; The end is loaded with 60 volts of civilian AC, and the AC current is between 10 and 30 amperes; pay a...

Embodiment 2

[0060] (1) Set up the electrolytic cell. The electrolytic cell has three groups of cells and six electrode chambers. The upper cross-section of the cell body is rectangular in size 160mm×45mm and 230mm in height; the bottom of the two electrode chambers of the same cell body is a semicircular arc In the same way, there is a gap of 20mm from the top of the second partition; the overflow hole is opened at a position of 30mm from the top, with a diameter of 10mm; a cylindrical graphite electrode with a spectral grade of Φ12mm and a length of 300mm is selected, a total of 12, fixed on the top cover, X, The distance between the Y electrodes is 100mm.

[0061] (2) 1200 grams of rhodium powder with a purity of 99.95% are evenly added to the bottom of the electrolytic cell, and the superior grade pure hydrochloric acid of 10mol / l is added from the feeding port until all tank bodies are filled; The terminal is loaded with 50 volts of civilian alternating current, and the alternating cu...

Embodiment 3

[0063] (1) Set up the electrolytic cell. The electrolytic cell has three groups of cells and six electrode chambers. The upper cross-section of the cell body is rectangular in size 140mm×50mm and 320mm in height; the bottom of the two electrode chambers of the same cell body is a semicircular arc In the same way, there is a gap of 20mm from the top of the second partition; the overflow hole is opened at a position of 70mm from the top, with a diameter of 10mm; a cylindrical graphite electrode with a spectral grade of Φ10mm and a length of 300mm is selected, a total of 12, fixed on the top cover, X, The distance between the Y electrodes is 100mm.

[0064] (2) 1200 grams of rhodium powder with a purity of 99.95% are evenly added to the bottom of the electrolytic cell, and the superior grade pure hydrochloric acid of 8mol / l is added from the feeding port until all tank bodies are filled; The terminal is loaded with 70 volts of civilian alternating current, and the alternating cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com