Miniature air-compression generator

A generator and air compressor technology, applied in engines, wind power generation, wind engines, etc., can solve the problems of not conforming to localization, difficulty in large-scale application, high price, etc., and achieve the effect of convenient space allocation on the bomb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

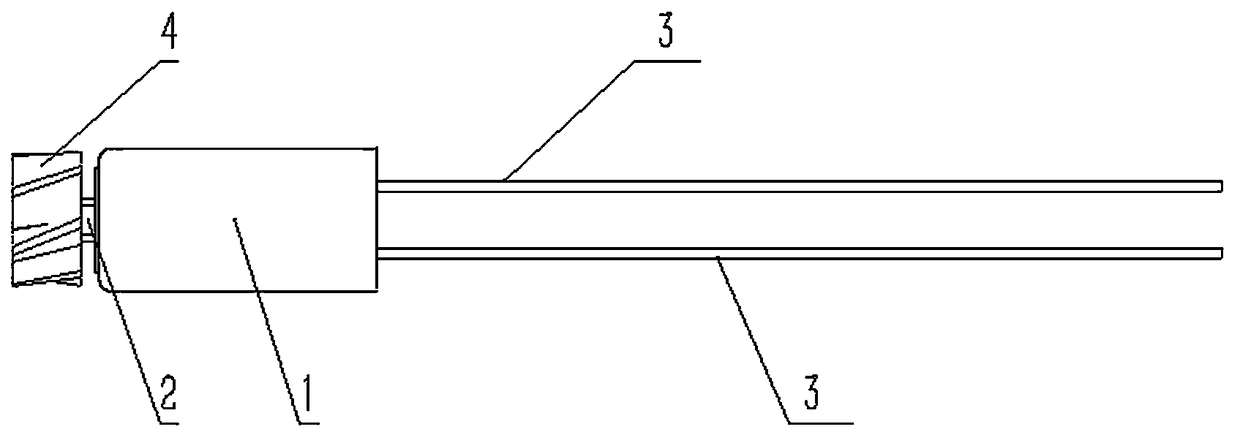

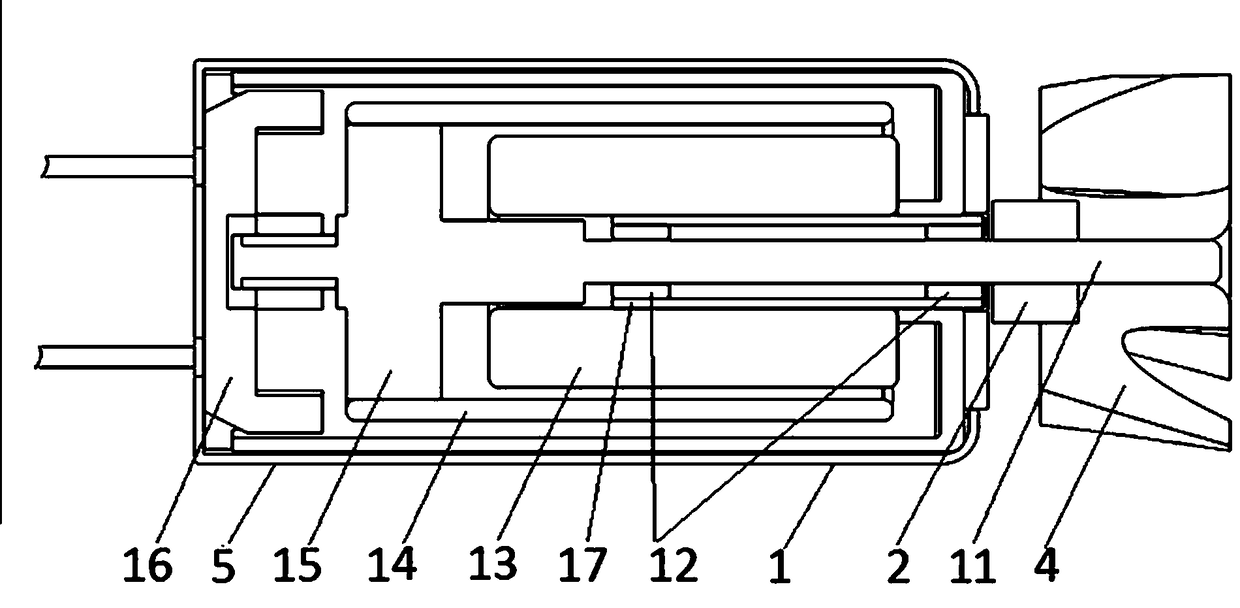

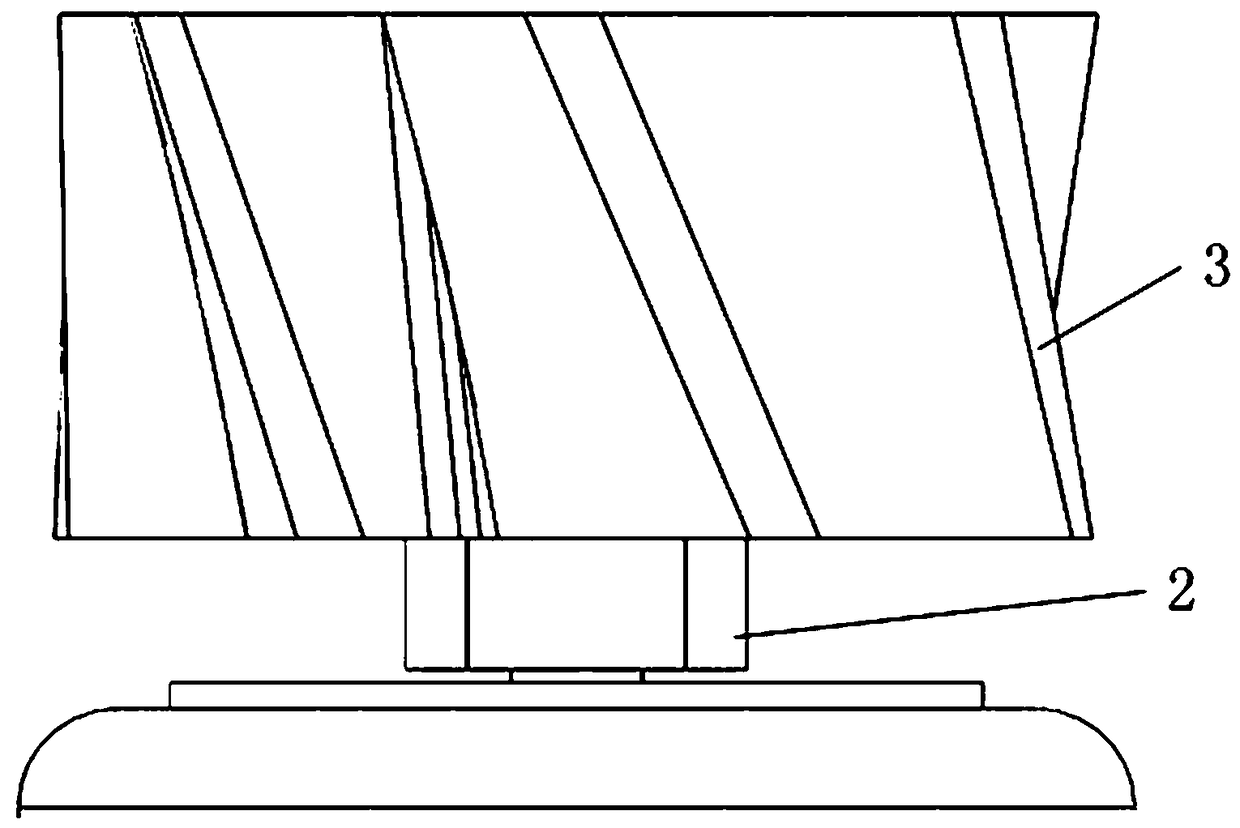

[0017] see Figure 1-6 , the miniature air compressor generator in the present embodiment is made up of motor body 1, axle sleeve 2, output line 3 and blade 4, and output line 3 is connected with motor body 1, and motor body 1 includes motor case 5, is installed in electric motor The motor shaft 11, support 15, coil 14, magnetic cover 13 and rear cover 16 in the casing 5, the blade 4 passes through one end of the motor shaft 11 and is installed on the shaft sleeve 2, the other end of the motor shaft 11 is connected with the support 15, and the coil 14 is installed on the bracket 15, the magnetic sleeve 13 is connected with the motor body 1 through the nested shaft 17, two bearing bushes 12 are embedded in the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com