Double-source heat pump suitable for bathing pool waste heat stepwise recycling

A dual-source heat pump, cascade recovery technology, applied in heat pump, heat transfer modification, heat exchange equipment and other directions, can solve problems such as waste heat energy waste, improve heat exchange capacity, facilitate assembly and fixation, and improve the effect of turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

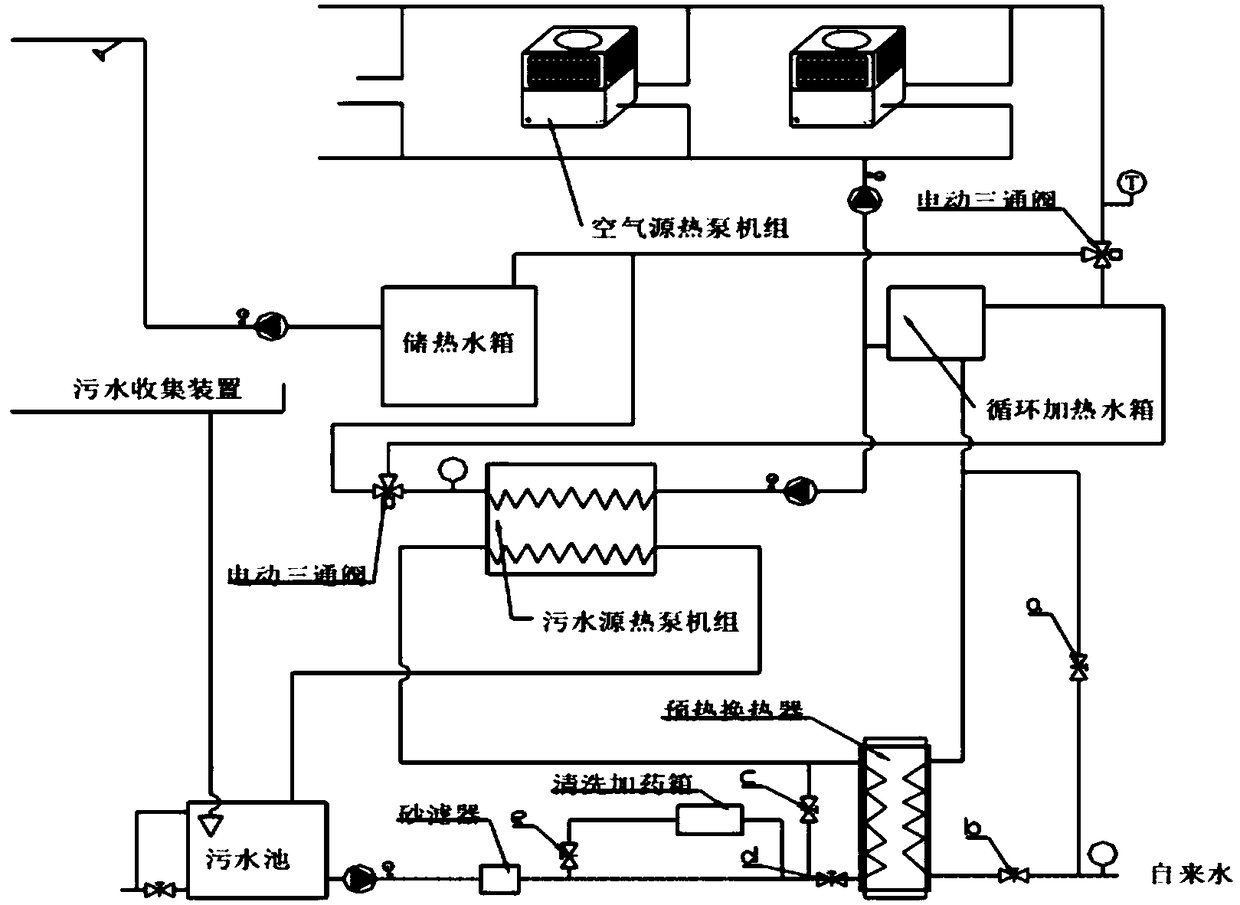

[0035] Such as Figure 1-8 As shown, a dual-source heat pump suitable for cascade recovery and utilization of waste heat in baths includes an air source heat pump unit and a sewage source heat pump unit. The object of waste heat recovery in the bath is the waste heat of sewage. The upper heat exchange tube with high sewage temperature is connected to the sewage source heat pump unit, and the lower heat exchange tube with low sewage temperature is connected to the air source heat pump unit. The air source heat pump unit is a "Z"-shaped double-fold exhaust gas evaporator.

[0036] There are two operating modes of the system, as follows:

[0037] (1) Turn on the air source heat pump unit and the sewage source heat pump unit at the same time to prepare hot water in the bath area during the peak bathing period. The air source heat pump unit supplements the excess heat to the lower part of the sewage tank through the refrigerant. (2) Turn on the sewage source heat pump unit during...

Embodiment 2

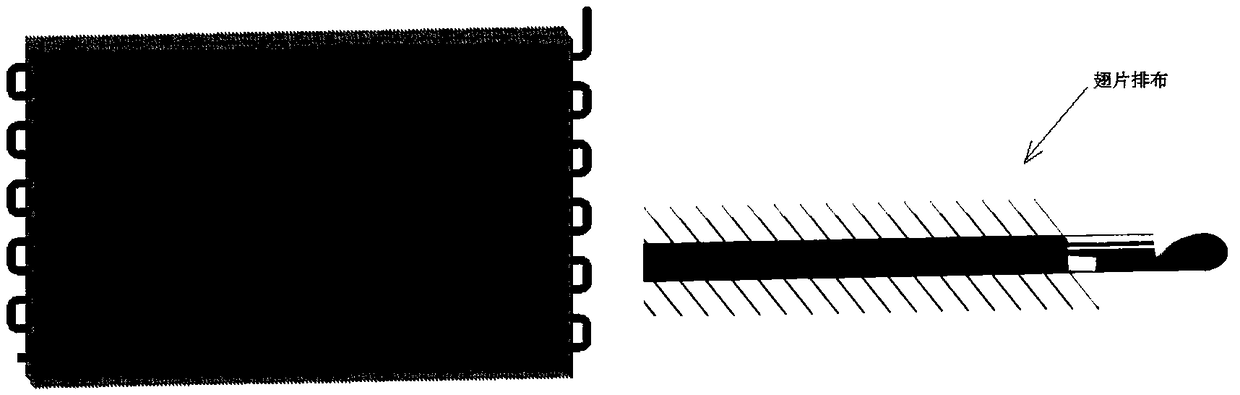

[0045] The difference from Example 1 is that the height h of the fins is 12.7 mm, the length of the twisted band is 40% of the length of the round tube, and the sewage heat exchanger is made of a ceramic heat exchange plate added with a rare earth heat-conducting material and a sub-section made of a PPR pipe. It is assembled from water joints, water distribution pipes and water collection pipes; the heat exchange plate is a strip plate with 3 circular tubular flow channels and 2 partition ribs, and multiple heat exchange plates are connected in series through the water distribution joints at both ends to form a heat exchange plate Assemblies, according to actual needs, multiple heat exchange plate assemblies are sequentially connected in parallel through the water collection pipe and the water distribution pipe to form the whole sewage heat exchanger.

Embodiment 3

[0047] The difference from Example 1 is that the height h of the fins is 19.05mm, the length of the twisted band is 30% of the length of the round tube, and the sewage heat exchanger is made of glass heat exchange plates added with rare earth heat-conducting materials and UPVC pipes. It is assembled from water joints, water distribution pipes and water collection pipes; the heat exchange plate is a strip plate with 20 circular tubular flow channels and 19 partition ribs, and multiple heat exchange plates are connected in series through the water distribution joints at both ends to form a heat exchange plate Assemblies, according to actual needs, multiple heat exchange plate assemblies are sequentially connected in parallel through the water collection pipe and the water distribution pipe to form the whole sewage heat exchanger.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap