A design method of a screw pump production system based on optimal solution

A production system and design method technology, applied in computing, biological neural network models, special data processing applications, etc., can solve problems such as insufficient adaptability, long design cycle, low accuracy, and achieve the effect of overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

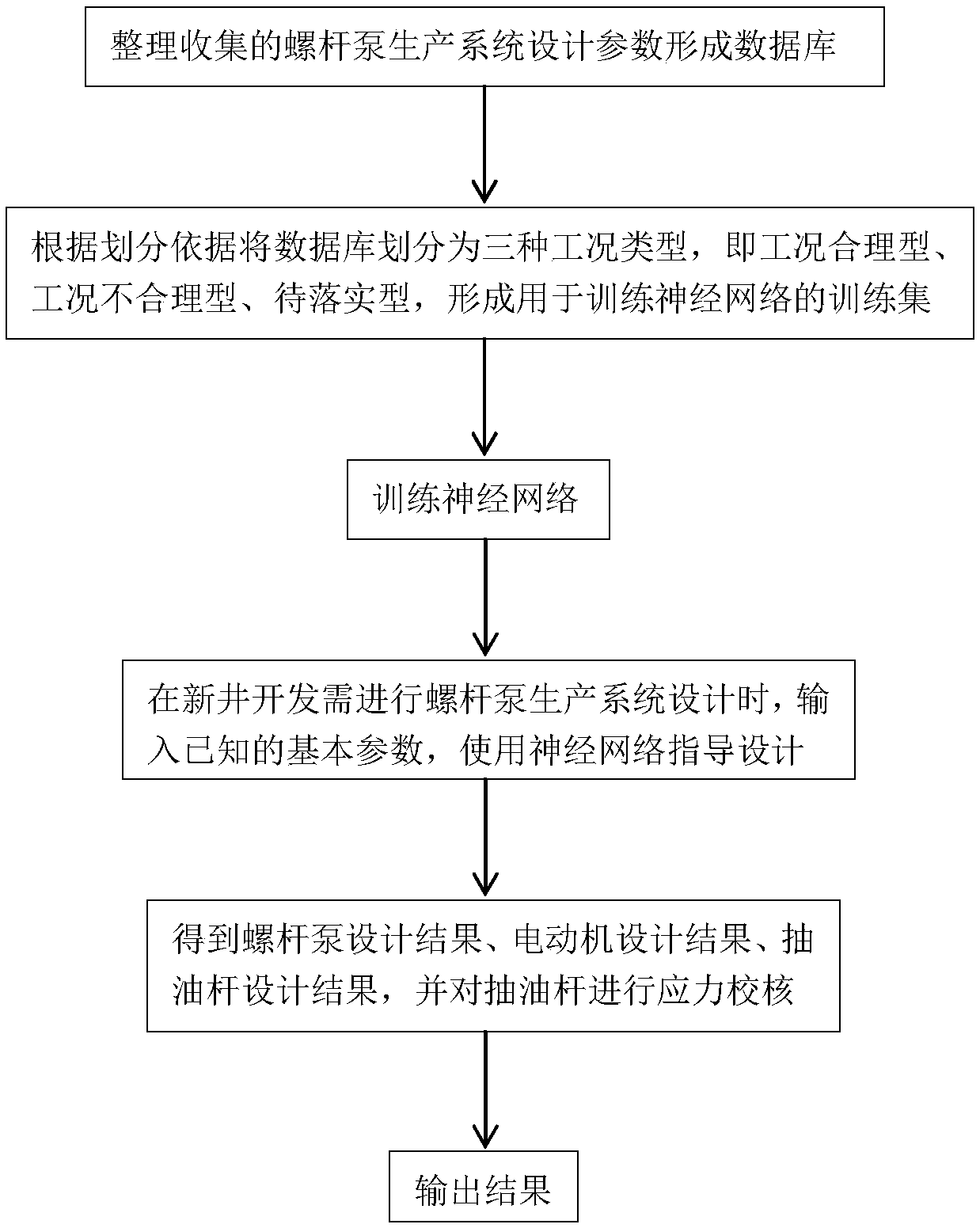

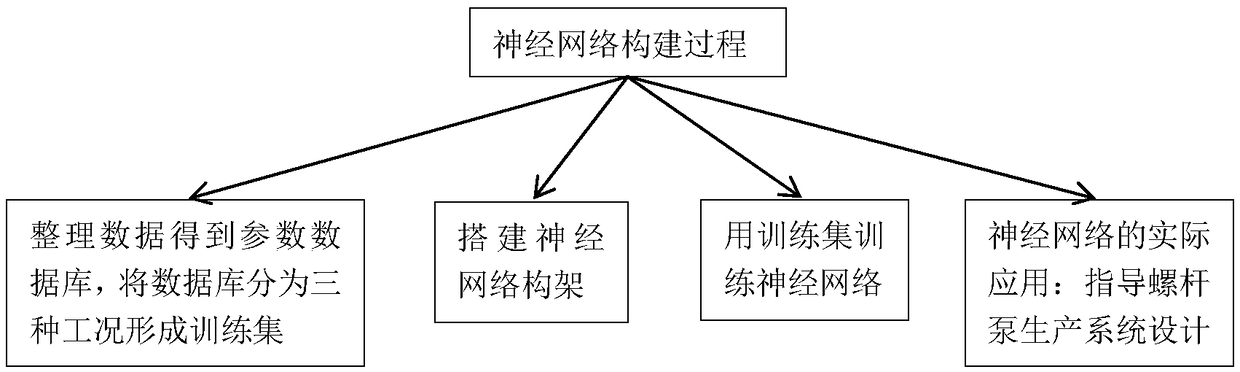

[0021] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0022] Such as figure 1 As shown, a design method of screw pump production system based on the optimal solution includes the following steps:

[0023] a. Construction of parameter database of screw pump production system:

[0024] Select the relevant parameter data of the PCP production system that has been in stable production for a period of time in different blocks and under different formation conditions for data sorting, and use the sorted data to form a parameter database.

[0025] The above parameter data mainly include oil layer depth, crude oil density, crude oil viscosity, stroke, stroke times, pump depth, pump diameter, liquid production, water co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com