Surface treatment method of silver evaporating material

A surface treatment and drying technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of high preparation cost of silver evaporation material, and achieve the effect of improving production environment, improving purity and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It can be seen from the background art that the preparation cost of silver evaporation material is relatively high. The reasons for the higher preparation cost of analyzing silver evaporated material are:

[0031] In order to remove the oxide layer on the surface of the silver evaporation material and improve the purity of the silver evaporation material, the surface treatment method of the silver evaporation material mainly includes pickling, cleaning and drying in sequence. However, the pickling solution used in the pickling operation is easy to consume silver material, thereby causing the loss of the silver evaporation material, which correspondingly increases the preparation cost of the silver evaporation material; and the use of acid is not conducive to the production environment. improve.

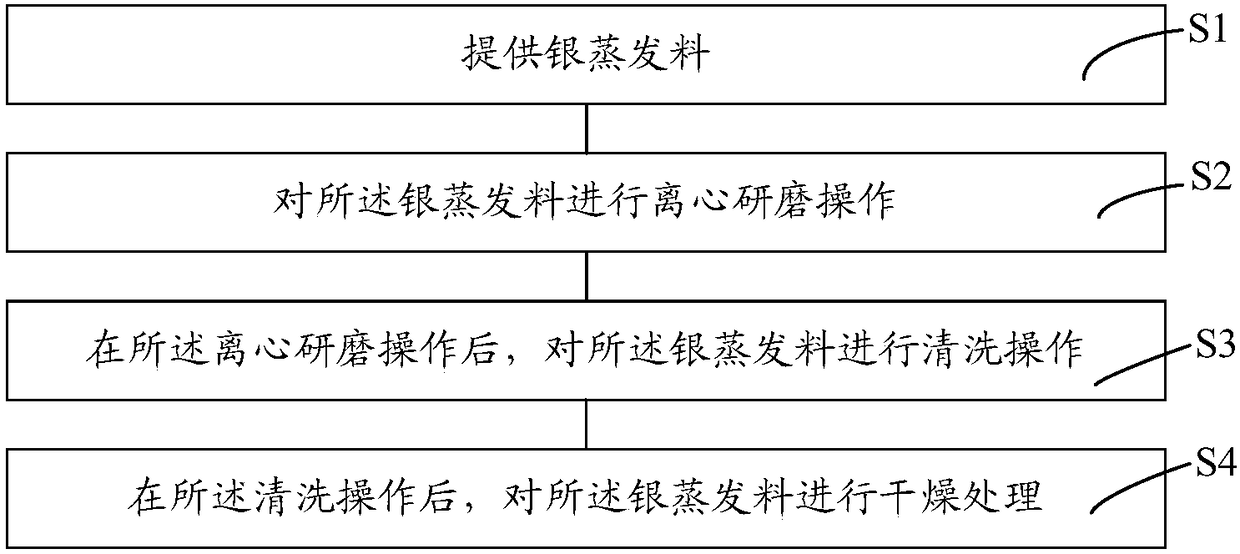

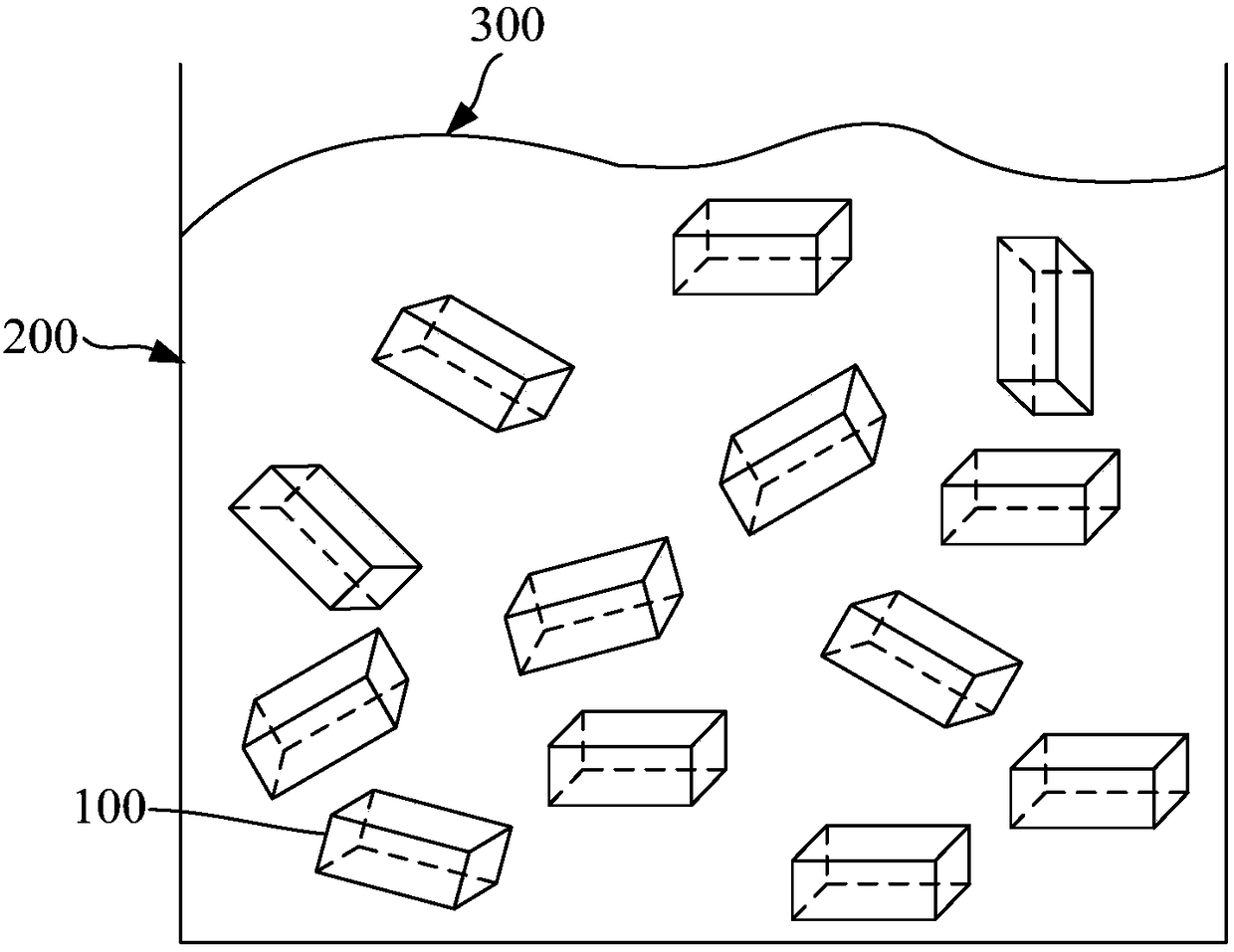

[0032] In order to solve the technical problem, the present invention carries out centrifugal grinding operation on the silver evaporation material to remove the oxide layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com