Processing method for long-life acrylic sheets

The technology of acrylic sheet and processing method is applied in the processing field of long-life acrylic sheet, which can solve the problems of reduced service life, poor toughness, and poor strength, which affect the popularization and use of acrylic products, and achieve long service life, good toughness, and other properties. Very competitive in the market and efficient in processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

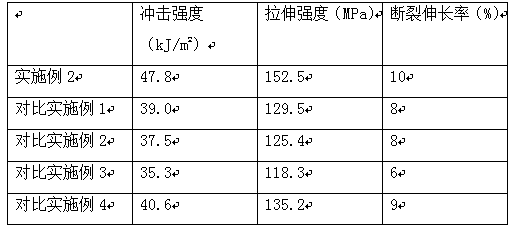

Examples

Embodiment 1

[0033] A method for processing long-life acrylic plates, comprising the steps of:

[0034] (1) Raw materials are weighed for backup:

[0035] Weigh the following raw materials in corresponding parts by weight for subsequent use: 180 parts of methyl methacrylate, 1.2 parts of dicumyl peroxide, 7 parts of ethylene glycol dimethacrylate, 6 parts of methyl chloroformate, 3 parts of dimethyl sulfate Ester, 10 parts of functional filler, 0.2 part of antioxidant, 0.1 part of ultraviolet absorber, 1 part of release agent;

[0036] (2) Mixed processing:

[0037] a. Mix the methyl methacrylate, dicumyl peroxide and ethylene glycol dimethacrylate weighed in step (1) evenly, then place them in a water bath for heating and polymerization treatment for 42 minutes, take them out and cool to Viscous plexiglass premix at room temperature for subsequent use;

[0038] b. Mix the plexiglass premix obtained in operation a with all the remaining raw material components in step (1), and then stir...

Embodiment 2

[0058] A method for processing long-life acrylic plates, comprising the steps of:

[0059] (1) Raw materials are weighed for backup:

[0060] Take the following raw materials by corresponding parts by weight for subsequent use: 190 parts of methyl methacrylate, 1.5 parts of dicumyl peroxide, 9 parts of ethylene glycol dimethacrylate, 8 parts of methyl chloroformate, 4 parts of dimethyl sulfate Esters, 12 parts of functional fillers, 0.3 parts of antioxidants, 0.2 parts of ultraviolet absorbers, 1.5 parts of mold release agents;

[0061] (2) Mixed treatment:

[0062] a. Mix the methyl methacrylate, dicumyl peroxide and ethylene glycol dimethacrylate weighed in step (1) evenly, then place them in a water bath for heating and polymerization treatment for 44 minutes, take them out and cool to Viscous plexiglass premix at room temperature for subsequent use;

[0063] b. Mix the plexiglass premix obtained in operation a with all the remaining raw material components in step (1), ...

Embodiment 3

[0083] A method for processing long-life acrylic plates, comprising the steps of:

[0084] (1) Raw materials are weighed for backup:

[0085] Take the following raw materials by corresponding parts by weight for subsequent use: 200 parts of methyl methacrylate, 1.8 parts of dicumyl peroxide, 10 parts of ethylene glycol dimethacrylate, 9 parts of methyl chloroformate, 5 parts of dimethyl sulfate Esters, 14 parts of functional fillers, 0.4 parts of antioxidants, 0.3 parts of UV absorbers, 2 parts of mold release agents;

[0086] (2) Mixed treatment:

[0087] a. Mix the methyl methacrylate, dicumyl peroxide and ethylene glycol dimethacrylate weighed in step (1) evenly, then place them in a water bath for heating and polymerization treatment for 46 minutes, take them out and cool to Viscous plexiglass premix at room temperature for subsequent use;

[0088] b. Mix the plexiglass premix obtained in operation a with all the remaining raw material components in step (1), and then s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com