A kind of refrigerator sterilizing cleaning agent

A technology for sterilizing cleaning agents and refrigerators, applied in the field of cleaning agents, can solve the problems of inability to remove and inhibit bacteria, and achieve the effects of thorough sterilization, enhanced adsorption and penetration, and non-toxic and harmless human body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

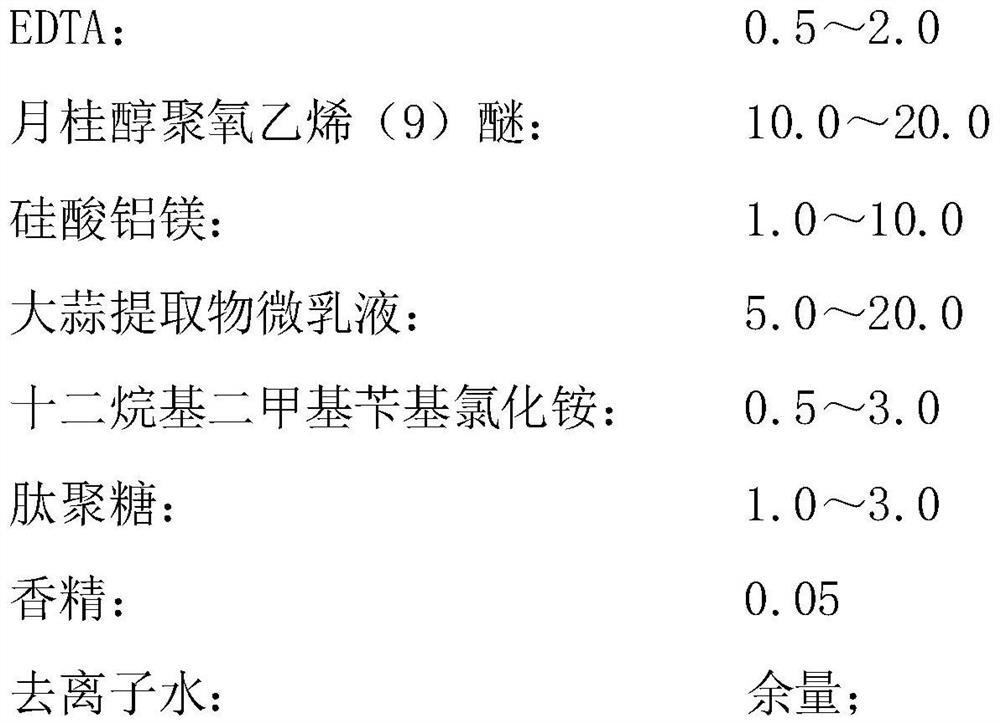

[0021] The sterilizing and cleaning agent for refrigerators described in this embodiment, in terms of 100 parts by mass, is obtained by adding the following raw materials into the reaction container and stirring them uniformly:

[0022]

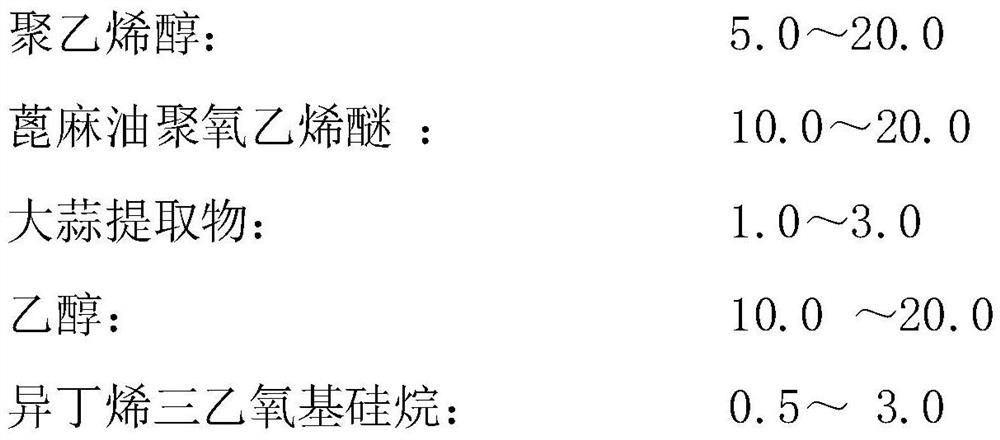

[0023] Wherein based on 100 parts by mass, the garlic extract microemulsion is composed of the following raw materials:

[0024]

[0025]

[0026] Wherein the preparation step of garlic extract microemulsion is:

[0027] First add polyvinyl alcohol and castor oil polyoxyethylene ether into deionized water and stir to mix evenly to obtain the water phase; then mix ethanol, isobutylene triethoxysilane and garlic extract to obtain the oil phase; then turn on the stirring The oil phase is slowly added dropwise to the water phase, and the stirring speed is 500 rpm to emulsify for 20 minutes to prepare the garlic extract microemulsion;

[0028] Wherein the preparation steps of garlic extract are:

[0029] (1) mash the garlic and enzymati...

Embodiment 2

[0034] The sterilizing and cleaning agent for refrigerators described in this embodiment, in terms of 100 parts by mass, is obtained by adding the following raw materials into the reaction container and stirring them uniformly:

[0035]

[0036]

[0037] Wherein based on 100 parts by mass, the garlic extract microemulsion is composed of the following raw materials:

[0038]

[0039] Wherein the preparation step of garlic extract microemulsion is:

[0040] First add polyvinyl alcohol and castor oil polyoxyethylene ether into deionized water and stir to mix evenly to obtain the water phase; then mix ethanol, isobutylene triethoxysilane and garlic extract to obtain the oil phase; then turn on the stirring The oil phase is slowly added dropwise to the water phase, and the stirring speed is 500 rpm to emulsify for 20 minutes to prepare the garlic extract microemulsion;

[0041] Wherein the preparation steps of garlic extract are:

[0042] (1) mash the garlic and enzymati...

Embodiment 3

[0047] The sterilizing and cleaning agent for refrigerators described in this embodiment, in terms of 100 parts by mass, is obtained by adding the following raw materials into the reaction container and stirring them uniformly:

[0048]

[0049] Wherein based on 100 parts by mass, the garlic extract microemulsion is composed of the following raw materials:

[0050]

[0051] Wherein the preparation step of garlic extract microemulsion is:

[0052] First add polyvinyl alcohol and castor oil polyoxyethylene ether into deionized water and stir to mix evenly to obtain the water phase; then mix ethanol, isobutylene triethoxysilane and garlic extract to obtain the oil phase; then turn on the stirring The oil phase is slowly added dropwise to the water phase, and the stirring speed is 500 rpm to emulsify for 20 minutes to prepare the garlic extract microemulsion;

[0053] Wherein the preparation steps of garlic extract are:

[0054] (1) mash the garlic and enzymatically hydrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com