Method for monitoring aging process of working state of optical module in real time

A technology of working status and aging process, which is applied in the field of optical communication network, can solve the problems of accelerating aging test time, shortening optical modules, etc., and achieves the effects of high test efficiency, simple circuit structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

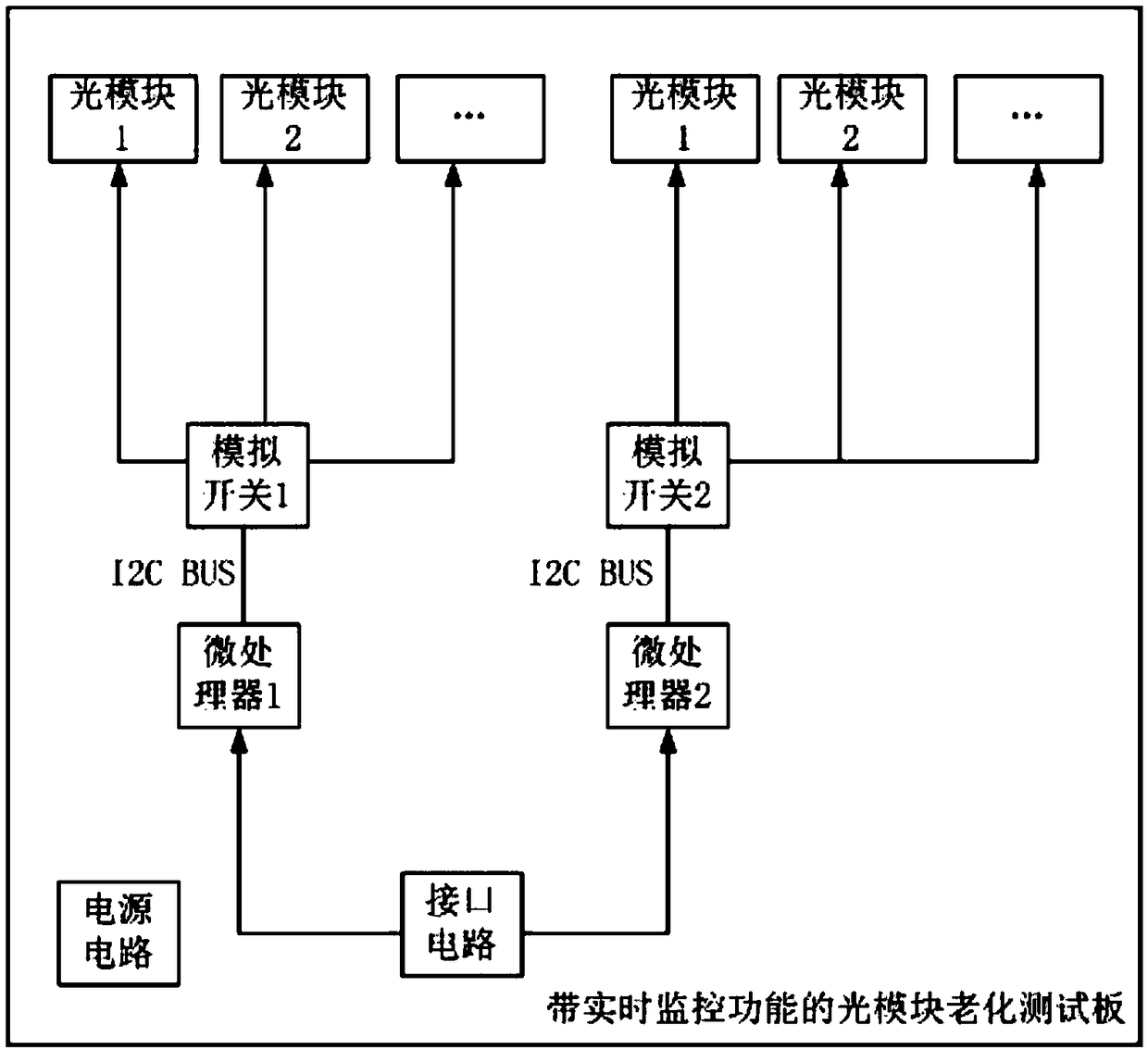

[0012] refer to figure 1 . According to the present invention, a method for real-time monitoring of the aging process of the working state of the optical module has the following technical characteristics: the interface circuit, the microprocessor, the analog switch and the power supply circuit providing the working power are arranged on the optical module aging test board, and the interface circuit At least two microprocessors are connected in parallel, and microprocessor 1 and microprocessor 2 are respectively connected in parallel to the information reading interfaces of n optical modules through analog switches 1 and 2 connected in series; the microprocessor is connected to the specified The optical module communication bus collects the data of the measured optical module, the interface circuit converts the I2C communication into the USB communication of the microprocessor, and transmits the monitored optical module aging information to the built-in automatic monitoring so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com