A quantum dot light emitting diode based on room temperature perovskite material and a preparation method thereof

A quantum dot light-emitting, perovskite material technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of complex preparation process, high color purity, size dependence, etc., to achieve simple preparation process, luminescence Improvement of efficiency and improvement of luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention also discloses a method for preparing a quantum dot light-emitting diode based on a room temperature perovskite material, comprising the following steps:

[0038] 1. Spin-coat and deposit (DEDOT:PSS) solution on the surface of ITO glass and perform heat treatment to obtain a hole injection layer; in step 1, the concentration of (DEDOT:PSS) solution is 1.3-1.7wt%, and the heat treatment temperature is 90-150°C , the processing time is 10-30 minutes;

[0039] 2. Deposit one or more mixtures of PTAA, Poly-TPD, TFB, PVK, NPB, TCTA, TAPC and CBP on the surface of the hole injection layer obtained in step 1 and heat treat to obtain the hole transport layer; step The temperature of the second heat treatment is 50-80°C, and the treatment time is 5-15 minutes;

[0040] 3. Spin-coat APbX on the surface of the hole transport layer obtained in step 2 3 Quantum dot dispersion and heat treatment to obtain perovskite quantum dot light-emitting layer, wherein, A is one ...

Embodiment 1

[0046] The preparation method of the quantum dot light-emitting diode based on the room temperature perovskite material described in this embodiment specifically includes the following steps:

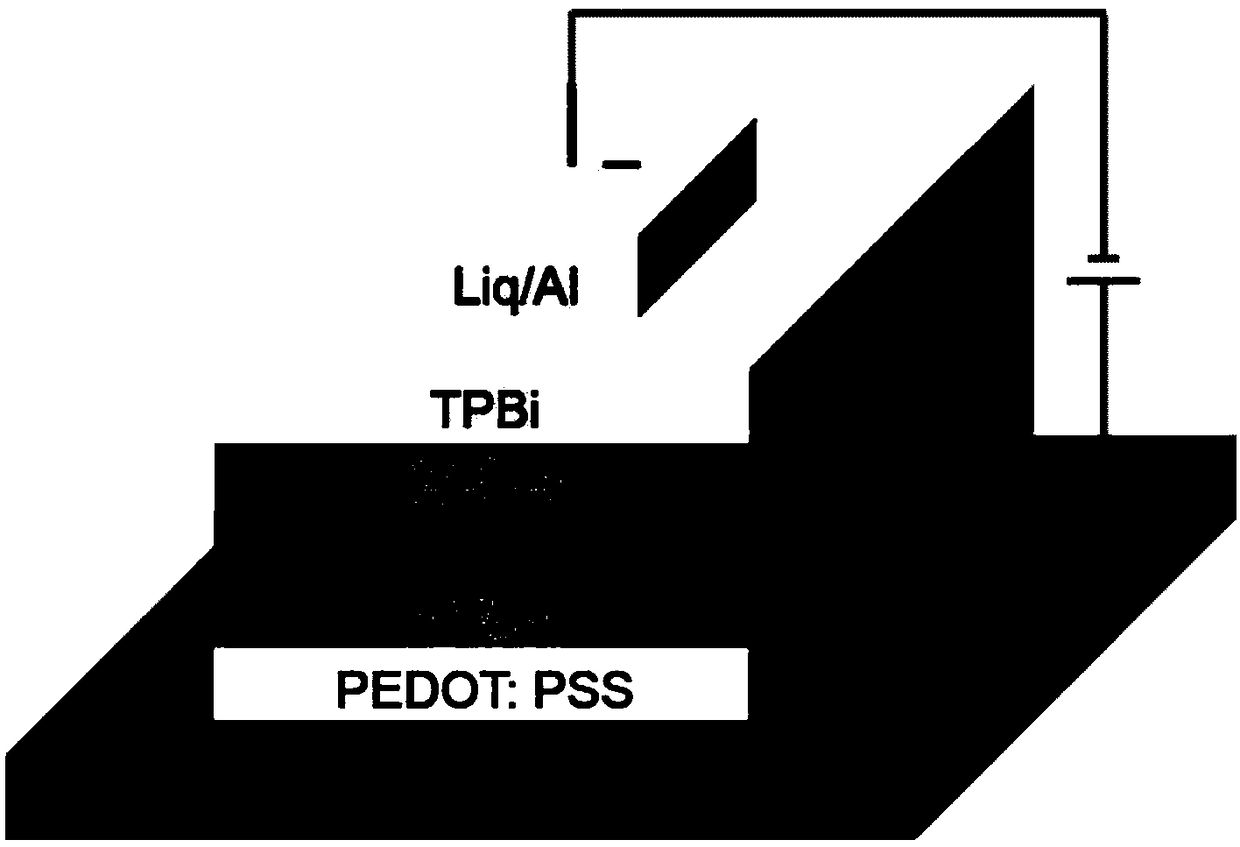

[0047] Step 1, spin-coat PEDOT:PSS solution on the cleaned ITO glass at a speed of 3000r / min, and anneal at 140°C for 15min;

[0048] Step 2, spin-coat PTAA solution at a speed of 3000r / min, and anneal at 120°C for 20min;

[0049] Step 3, Spin-coat CsPbBr prepared at room temperature 3 Quantum dot dispersion, rotating speed is 2000r / min, annealing at 60°C for 10min; CsPbBr 3 The quantum dot dispersion is prepared at room temperature;

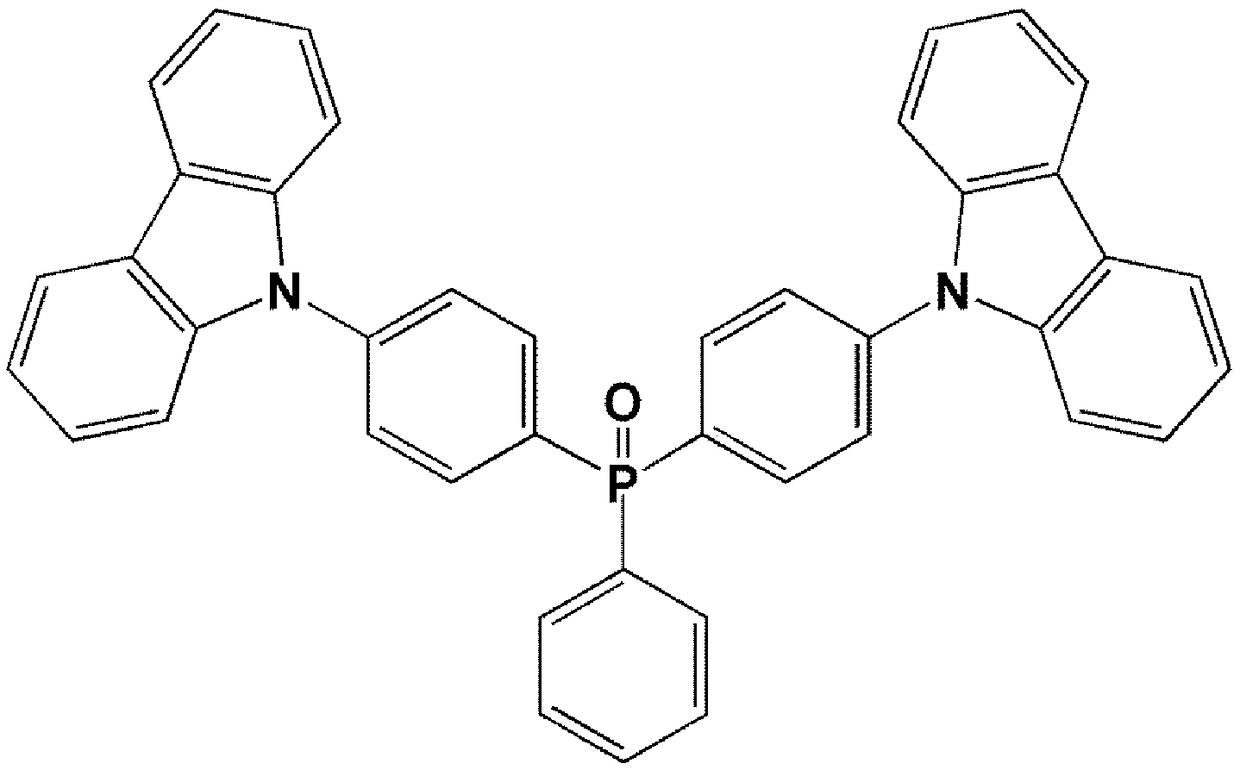

[0050] Step 4, depositing BCPO by thermal evaporation, the deposition thickness is 10nm;

[0051] Step 5, depositing TPBi by thermal evaporation method, the deposition thickness is 40nm;

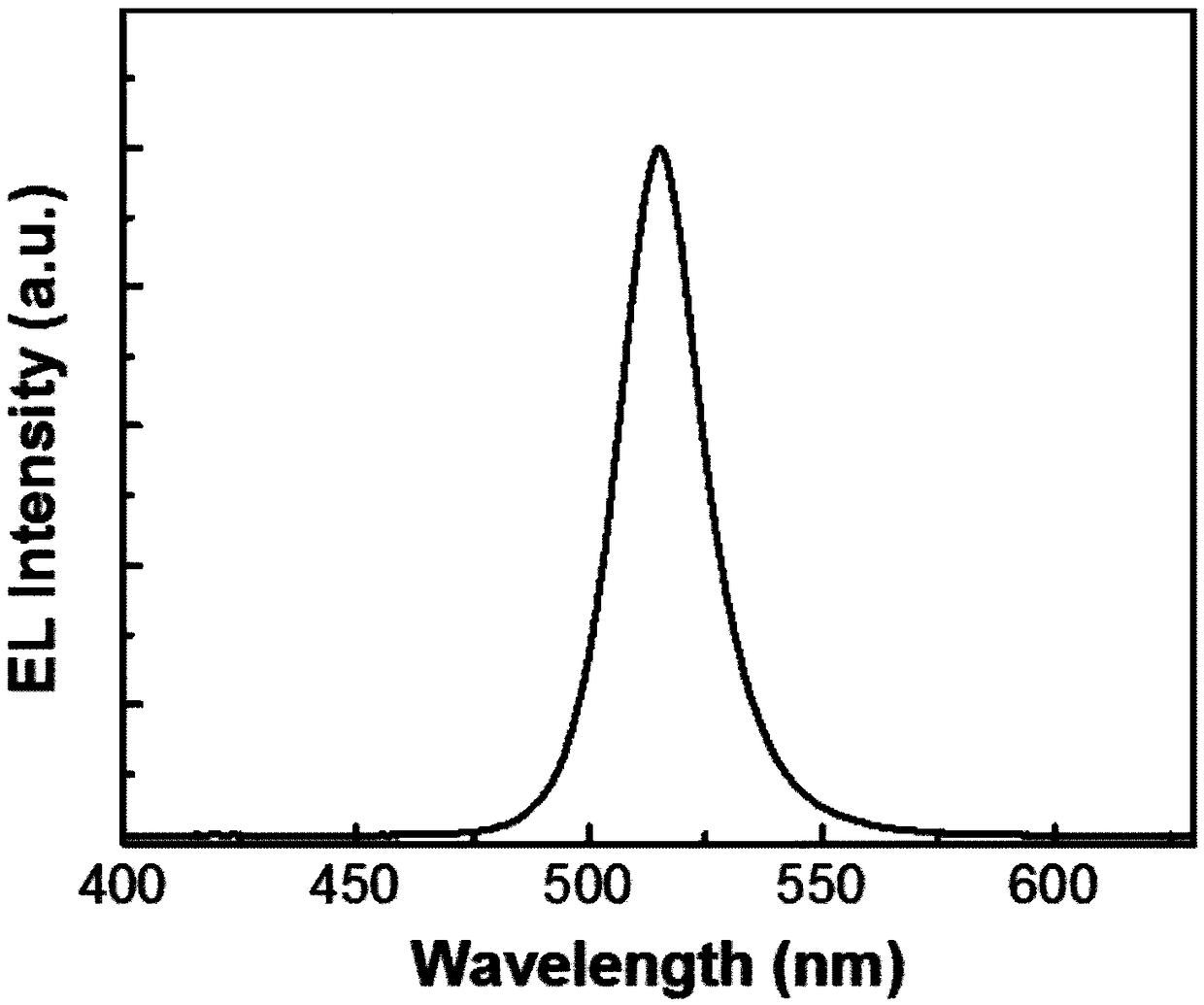

[0052] Step 6, depositing Liq / Al electrodes with a mask plate by thermal evaporation method, with a thickness of 2 / 100nm, to obtain room temperature CsPbBr 3 Perov...

Embodiment 2

[0056] Similar to Example 1, the difference is that the PTAA in step 2 of Example 1 is changed to any one of Poly-TPD, TFB and PVK, and other conditions are kept the same to obtain CsPbBr 3 Perovskite quantum dot light-emitting diodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com