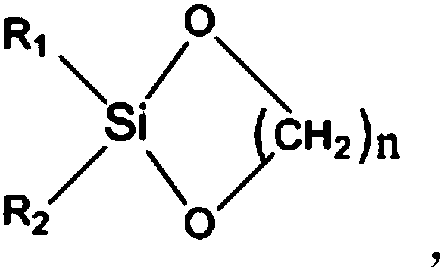

Application of cyclic silicate compounds in battery electrolyte

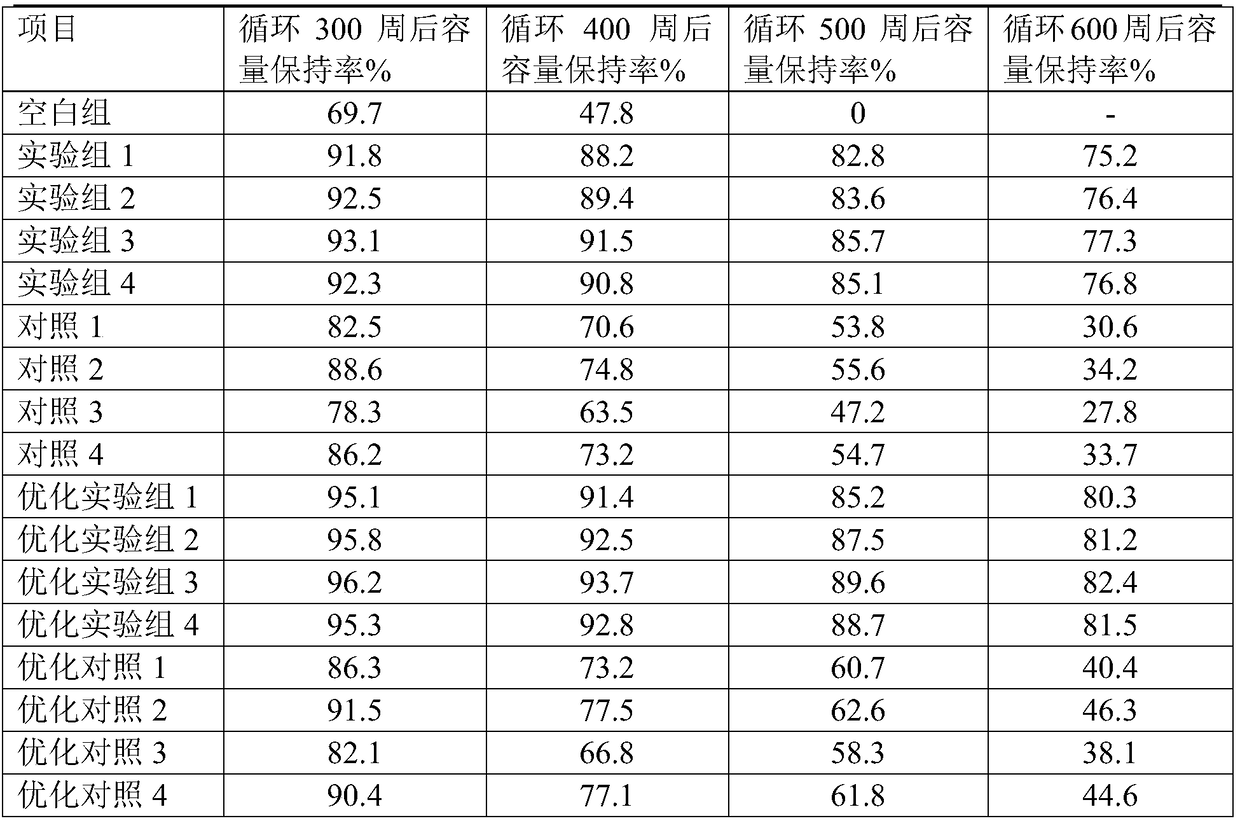

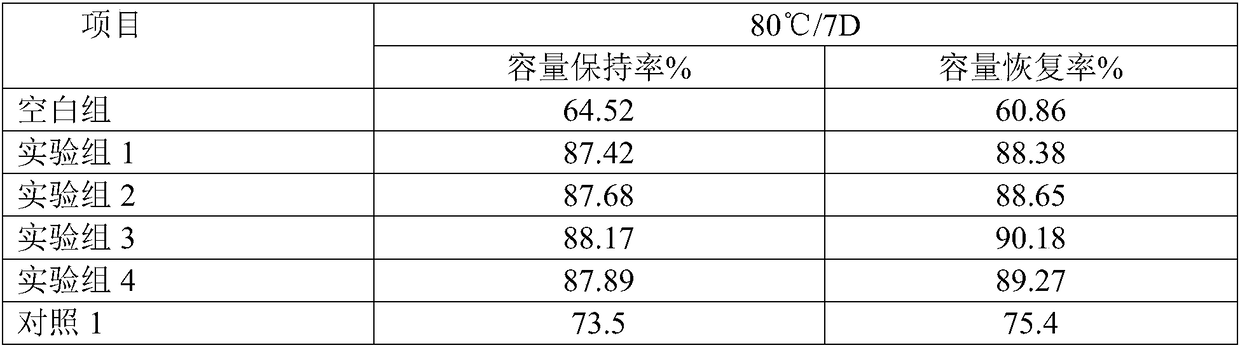

A silicate and compound technology, applied in the direction of silicon organic compounds, compounds of elements of Group 4/14 of the periodic table, secondary batteries, etc., can solve the problems of battery capacity loss, battery performance reduction, and manufacturing cost increase, etc. To achieve the effect of improving high temperature cycle performance, increasing storage performance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The battery electrolyte includes a lithium salt, an organic solvent and a cyclic silicate compound in a mass ratio of 20:79.99:0.01. The organic solvent is ethylene carbonate and methyl trifluoroacetate in a volume ratio of 40:60. The lithium salt is LiPF 6 , concentration 1mol / L. The additive is dimethyl silicate-1,4-butylene glycol ester, the purity is 99.6%, the moisture content is 34ppm, and the acid value is 42ppm

Embodiment 2

[0021] The battery electrolyte includes a lithium salt, an organic solvent and a cyclic silicate compound in a mass ratio of 20:70:10. The organic solvent is propylene carbonate, methyl propionate, and butyl trifluoroacetate in a volume ratio of 30:40:30. Described lithium salt is LiBF 4 , concentration 1mol / L. The additive is 1,5-pentanediol dimethyl silicate with a purity of 99.72%, a water content of 28 ppm and an acid value of 32 ppm.

Embodiment 3

[0023] The battery electrolyte includes a lithium salt, an organic solvent and a cyclic silicate compound in a mass ratio of 15:80:5. The organic solvent is gamma-butyrolactone and diethyl carbonate with a volume ratio of 50:50. The lithium salt is LiPF 6 , concentration 1mol / L. The additive is ethylene glycol diethyl silicate with a purity of 99.68%, a moisture content of 30 ppm, and an acid value of 37 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com