Creep feed capable of improving production performance of suckling piglets by cured raw material and preparation method of creep feed

A technology for production performance and suckling piglets, applied in the field of feed, can solve the problems of piglet intestinal dysfunction, low processing efficiency, and affecting piglet digestion and absorption, and achieve the goal of improving daily weight gain, improving production performance, and increasing digestion and absorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

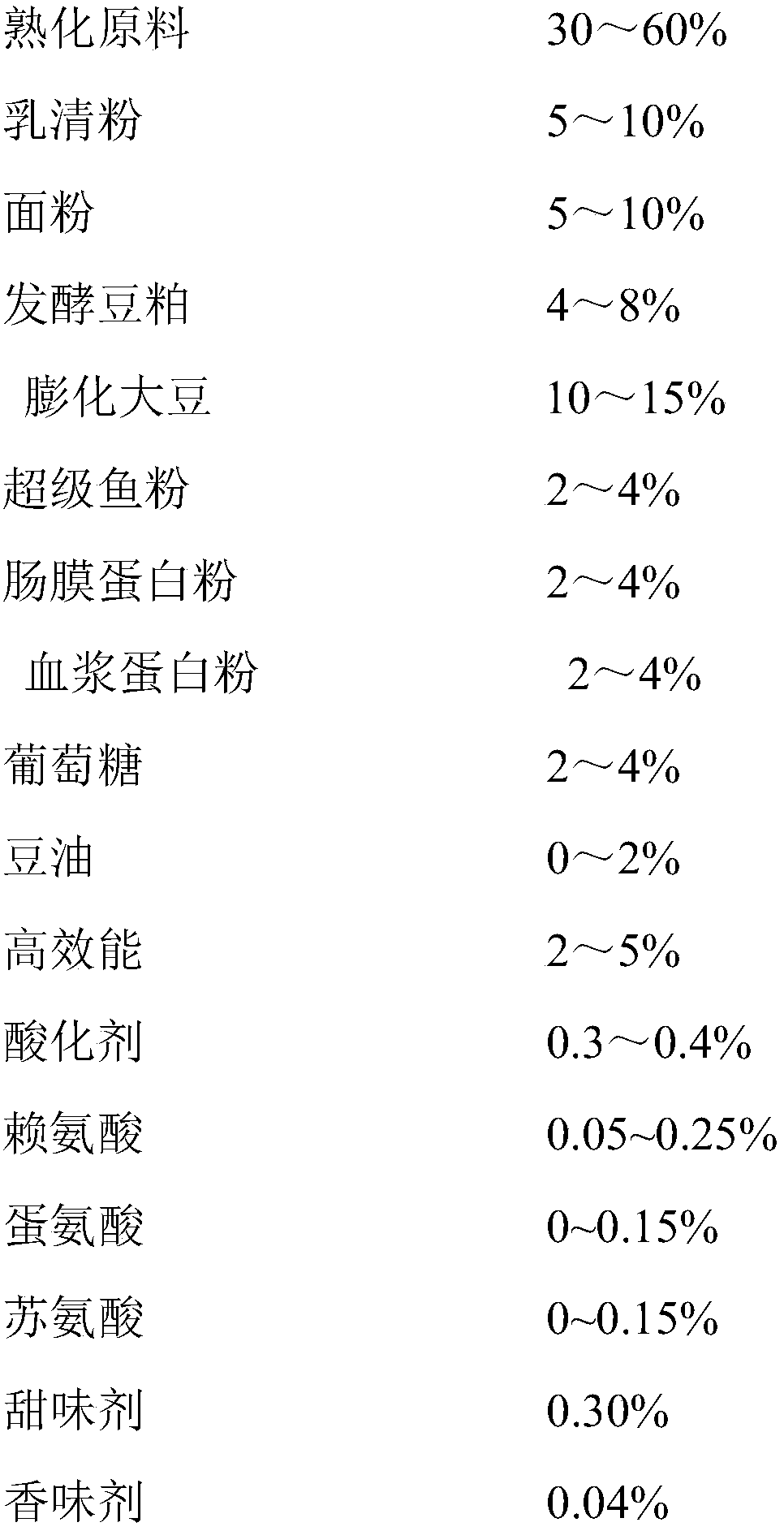

[0039]One, the feed formula for teaching trough of the present invention is as follows:

[0040]

[0041]

[0042] The aging raw material is prepared by the following process: (1) mix corn, soybean meal and broken rice according to the ratio of 2:1, put them into a mixer for mixing, and the mixing time is 160s; (2) mix well The raw material mixture is sent into a pulverizer for crushing until the particle size is less than 1.8mm (the sieve of the pulverizer is 1.8mm*1.8mm); (3) the pulverized raw material mixture is puffed, and the temperature of the puffing machine is 130°C; (4) Cool the puffed raw material mixture; (5) Send the cooled puffed raw material mixture into a pulverizer for secondary crushing to a size of 1.0-1.2 mm; (6) Put the secondary pulverized puffed raw material The mixture is then put into a mixer for secondary mixing, and the mixing time is 160s to obtain the ripened raw material (ie, the puffed mixture of corn, soybean meal, and broken rice); (7) pa...

Embodiment 2

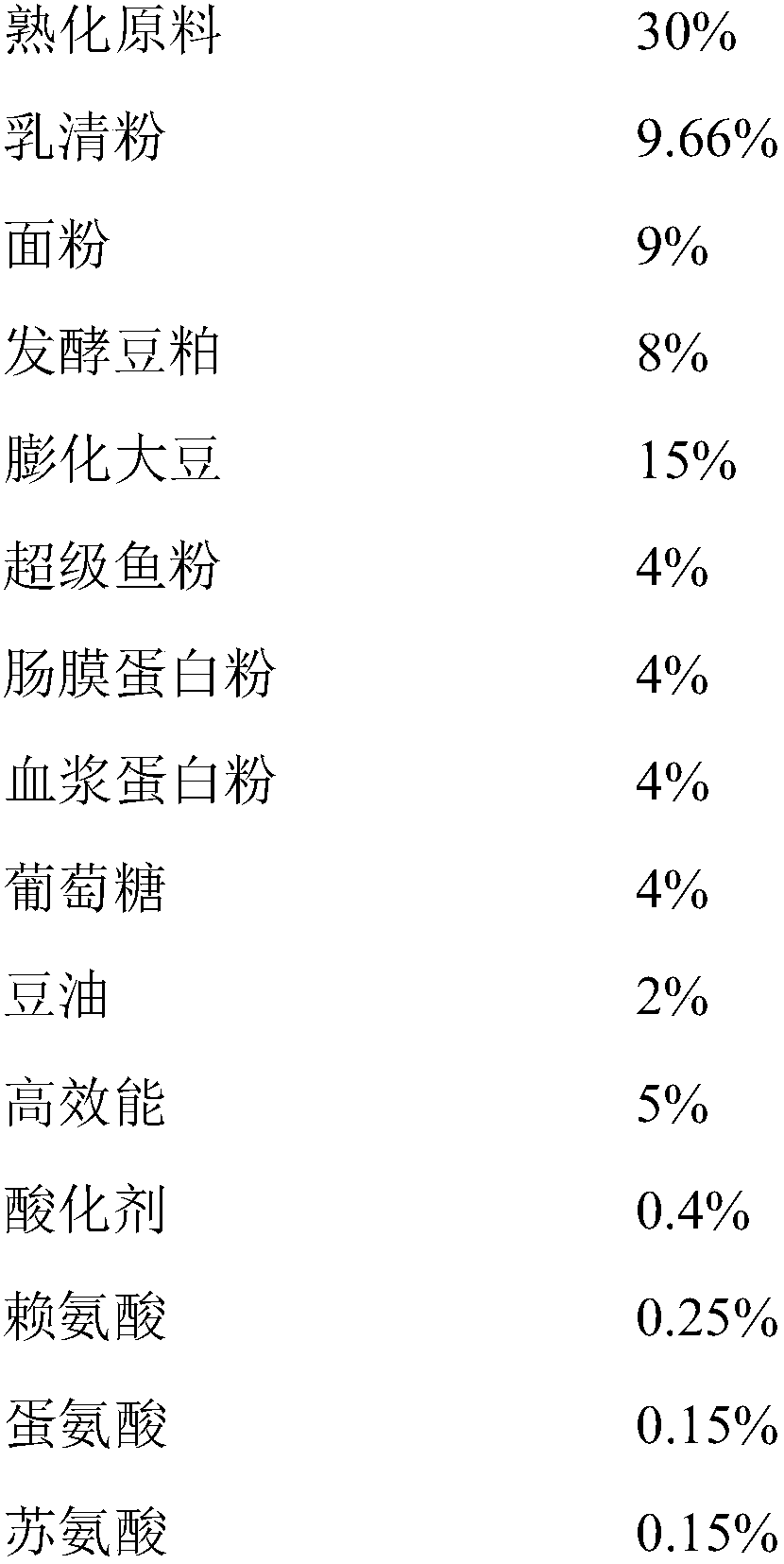

[0055] One, the feed formula for teaching trough of the present invention is as follows:

[0056]

[0057]

[0058] The aging raw material is prepared by the following process: (1) mix corn, soybean meal and broken rice according to the ratio of 3:1, put them into a mixer for mixing, and the mixing time is 150s; (2) mix well The raw material mixture is sent into a pulverizer for crushing until the particle size is less than 1.8mm (the sieve of the pulverizer is 1.8mm*1.8mm); (3) the pulverized raw material mixture is puffed, and the temperature of the puffing machine is 135°C; (4) Cool the puffed raw material mixture; (5) Send the cooled puffed raw material mixture into a pulverizer for secondary crushing to a size of 1.0-1.2 mm; (6) Put the secondary pulverized puffed raw material The mixture is put into the mixer for secondary mixing, and the mixing time is 150s to obtain the ripened raw material (ie, the puffed mixture of corn, soybean meal, and broken rice); (7) pack...

Embodiment 3

[0071] One, the feed formula for teaching trough of the present invention is as follows:

[0072]

[0073] The aging raw material is prepared by the following process: (1) mix corn, soybean meal and broken rice according to the ratio of 2.5:1, put them into a mixer for mixing, and the mixing time is 155s; (2) mix well The raw material mixture is sent into a pulverizer for crushing until the particle size is less than 1.8mm (the sieve of the pulverizer is 1.8mm*1.8mm); (3) the pulverized raw material mixture is puffed, and the temperature of the puffing machine is 132°C; (4) Cool the puffed raw material mixture; (5) Send the cooled puffed raw material mixture into a pulverizer for secondary crushing to a size of 1.0-1.2 mm; (6) Put the secondary pulverized puffed raw material The mixture is put into the mixer for secondary mixing, and the mixing time is 155s to obtain the ripened raw material (ie, the puffed mixture of corn, soybean meal, and broken rice); (7) packing the ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com