Preparation method of low-acid green vegetables fermented in bag

A green vegetable and low-acid technology, which is applied in the field of biotechnology and food, can solve the problems of difficulty in realizing large-scale standardized production, high production cost of fermented low-acid green vegetables, and large discharge of high-salt and high-acid wastewater, so as to ensure normal fermentation, Prevents oxidative discoloration and suppresses infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

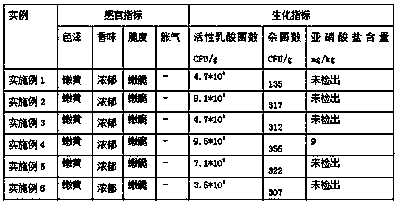

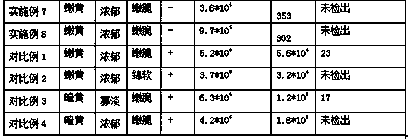

Examples

Embodiment 1

[0095] This embodiment is illustrated by taking 600 kg of green vegetables to make fermented low-acid green vegetable pickles as an example after the green vegetables are pretreated.

[0096] Pretreatment: pretreat the green vegetables to remove impurities and inedible parts, then process the green vegetables into nodular shapes, wash them, and set aside.

[0097] Disinfection and cleaning: Take 600kg of pretreated vegetables, treat them with trichloroisocyanuric acid with a mass concentration of 0.01g / ㎏ for 3 minutes, rinse them with clean water for 3 minutes, and drain them for later use.

[0098] Dehydration: put the rinsed greens into a mixer, add 14kg of iodine-free salt, stir and let stand for 5 hours, then use a three-legged centrifuge to centrifuge and dehydrate at a speed of 1000r / min for 3 minutes; The green vegetables after dehydration are 450kg, and total yield is 75%. The green vegetables of 450kg are put into the mixer again.

[0099] Raw materials: take 450kg ...

Embodiment 2

[0116] The difference between this example and Example 1 is that this example uses chlorine dioxide with a mass concentration of 0.12 g / kg for 4 minutes, then rinses with water for 5 minutes, and drains for later use.

[0117] Fermentation: place the vacuum-sealed packaging bag at 29°C and ferment for 50 days to obtain a fermented low-acid green vegetable kimchi product.

Embodiment 3

[0119] This embodiment is illustrated by taking 100 kg of green vegetables to make fermented low-acid green vegetable pickles as an example after the green vegetables are pretreated.

[0120] Pretreatment: pretreat the green vegetables to remove impurities and inedible parts, then process the green vegetables into lumps, wash and set aside.

[0121] Disinfection and cleaning: Take 100kg of pretreated vegetables, treat them with trichloroisocyanuric acid with a mass concentration of 0.05g / ㎏ for 5 minutes, rinse them with clean water for 5 minutes, and drain them for later use.

[0122] Dehydration: put the washed greens into a blender, add 7kg of iodine-free salt, stir and place for 24 hours, then use a three-legged centrifuge to dehydrate, and the three-legged centrifuge is centrifuged at a speed of 2000r / min for 10 minutes; The green vegetables after dehydration are 56kg, and total yield is 56%. The green vegetables of 56kg are put into the mixer again.

[0123] Raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com