Method for preparing low-salt content soy sauce

A preparation method, technology of salt content, applied in the field of food processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

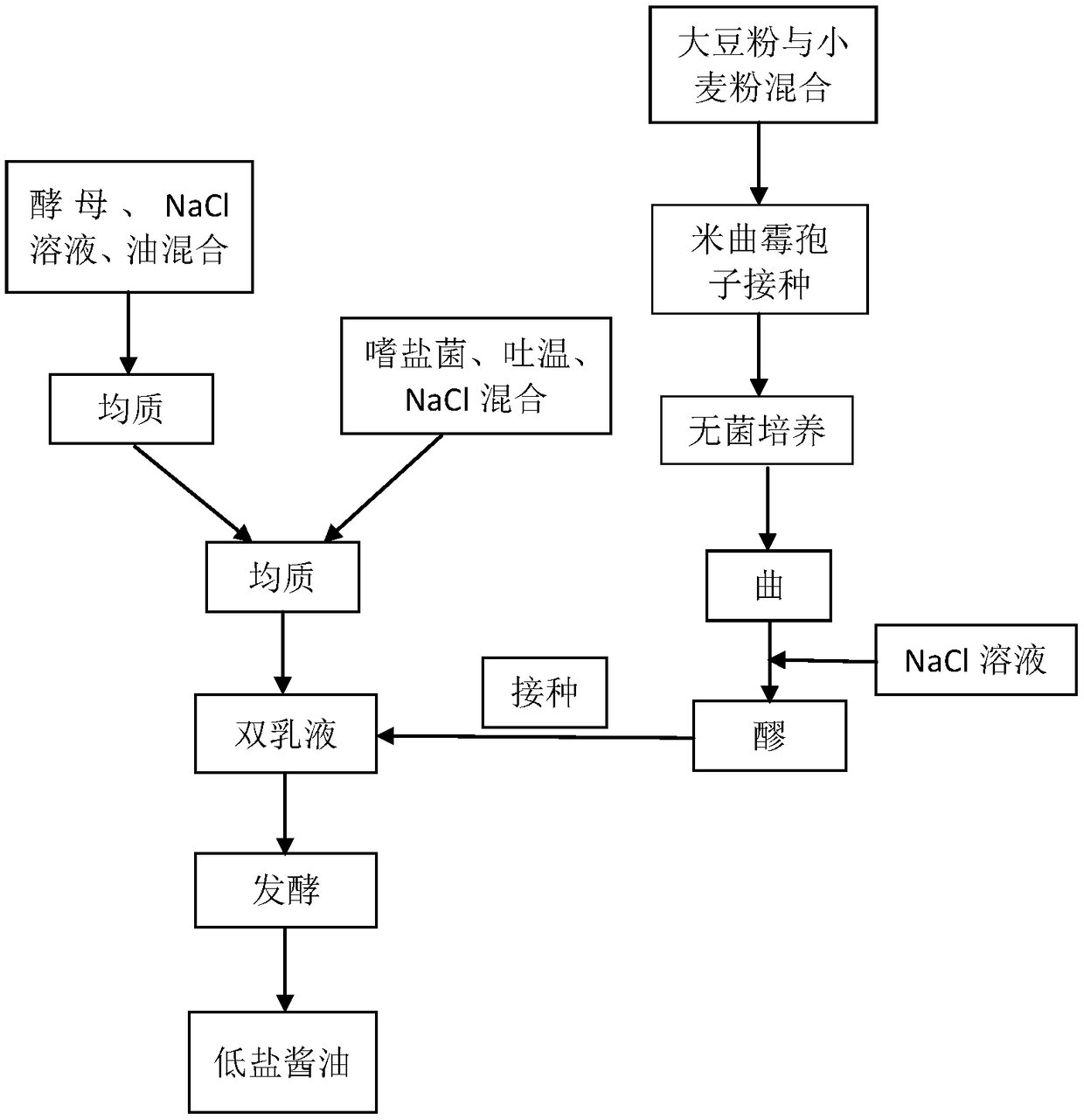

Method used

Image

Examples

Embodiment 1

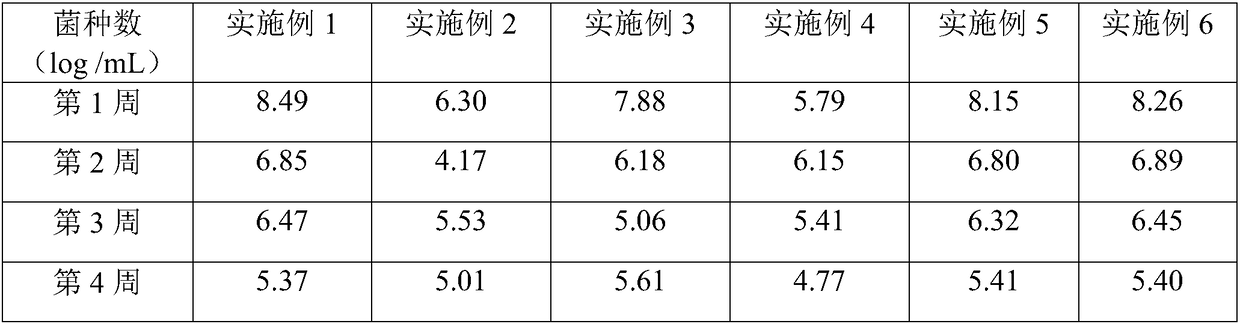

[0020] Embodiment 1: a kind of preparation method of low-salt content soy sauce, this method comprises the following steps: (1) Luxie yeast suspension is added in 6% (w / v) sterile NaCl solution, regulates cell with hemocytometer concentration so that the number of cells is 10 7 c / ml, this solution is W 1 , will W 1 Mix into soybean oil at a ratio of 20:80 and high pressure homogenize 1 time at 1700rpm to prepare W 1 -O primary emulsion; (2) 2ml of halophilic bacteria, 1% wt Tween 80 and 6% (w / v) NaCl aqueous solution are mixed to obtain W 2 solution, the W 1 -O Primary Emulsion with W 2 The solution was mixed again at a ratio of 20:80 and homogenized once more at 2000 rpm to obtain the final W 1 -O-W 2 Double emulsion; (3) Fully mix the sterilized soybean flour and wheat flour in a ratio of 1:1, inoculate the mixture with Aspergillus oryzae spores and adjust its concentration to 10 with a hemocytometer 5 Spores / g, after being sterilized at 121°C for 15 minutes by an ult...

Embodiment 2

[0021] Embodiment 2: a kind of preparation method of low-salt content soy sauce, this method comprises the following steps: (1) Luxie yeast suspension is added in 6% (w / v) sterile NaCl solution, regulates cell with hemocytometer concentration so that the number of cells is 10 7 c / ml, this solution is W 1 , will W 1 Mix into soybean oil at a ratio of 20:60 and high pressure homogenize 1 time at 1700rpm to prepare W 1 -O primary emulsion; (2) 2ml of halophilic bacteria, 1% wt Tween 80 and 6% (w / v) NaCl aqueous solution are mixed to obtain W 2 solution, the W 1 -O Primary Emulsion with W 2 The solution was mixed again at a ratio of 20:60 and homogenized once more at 2000 rpm to obtain the final W 1 -O-W 2 Double emulsion; (3) Fully mix the sterilized soybean flour and wheat flour in a ratio of 1:1, inoculate the mixture with Aspergillus oryzae spores and adjust its concentration to 10 with a hemocytometer 5 Spores / g, after being sterilized at 121°C for 15 minutes by an ult...

Embodiment 3

[0022] Embodiment 3: a kind of preparation method of low-salt content soy sauce, this method comprises the following steps: (1) Luxie yeast suspension is added in 6% (w / v) sterile NaCl solution, regulates cell with hemocytometer concentration so that the number of cells is 10 7 c / ml, this solution is W 1 , will W 1 Mix into soybean oil at a ratio of 20:40 and high pressure homogenize 1 time at 1700rpm to prepare W 1 -O primary emulsion; (2) 2ml of halophilic bacteria, 1% wt Tween 80 and 6% (w / v) NaCl aqueous solution are mixed to obtain W 2 solution, the W 1 -O Primary Emulsion with W 2 The solution was mixed again at a ratio of 20:40 and homogenized once again at 2000 rpm to obtain the final W 1 -O-W 2 Double emulsion; (3) Fully mix the sterilized soybean flour and wheat flour in a ratio of 1:1, inoculate the mixture with Aspergillus oryzae spores and adjust its concentration to 10 with a hemocytometer 5Spores / g, after being sterilized at 121°C for 15 minutes by an ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com