A kind of preparation method of melatonin microneedle patch

A technology of melatonin and microneedle patch, which is applied in the field of preparation of melatonin microneedle patch, which can solve the problems of uncomfortable administration, low bioavailability, deposition of microneedle materials, etc., and achieve good skin compatibility and application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

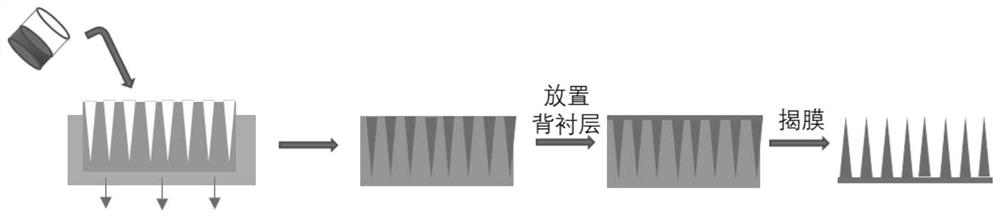

[0031] Preparation of melatonin microneedles made of PVA, sodium carboxymethylcellulose and dextran

[0032] Prepare the mixed solution of PVA solution and sodium carboxymethyl cellulose and dextran respectively;

[0033] After mixing the mixed solution of melatonin, PVA solution, sodium carboxymethylcellulose and dextran, it is poured onto a polytetrafluoroethylene mold with a microhole array, and the back of the mold is vacuumed to make the The liquid medicine is completely filled into the micropores, and then a backing layer prepared from a polymer solution is laid on the front of the mold, and the mold and the backing layer loaded with the liquid medicine are subjected to two freeze-thaw cycle operations together , separating the microneedles together with the backing layer from the mold, and finally drying the microneedles to obtain the melatonin microneedle patch.

Embodiment 2

[0035] Preparation of melatonin microneedles made of PVA, sodium carboxymethylcellulose and dextran

[0036] Prepare the mixed solution of PVA solution and sodium carboxymethyl cellulose and dextran respectively;

[0037] Mix the mixed solution of melatonin, PVA solution, sodium carboxymethylcellulose and dextran, wherein the solid content of PVA accounts for 5%. Pour the mixed liquid medicine on the polytetrafluoroethylene mold with micro-hole array, vacuumize the back of the mold, so that the liquid medicine can be completely filled into the micro-holes, and then spread a layer on the front of the mold The backing layer prepared by polymer solution is used to freeze and thaw the mold and the backing layer loaded with the liquid medicine twice, and the microneedles and the backing layer are separated from the mold. It is difficult to remove the film and the liquid medicine is uniform remains in the mold.

Embodiment 3

[0039] Preparation of melatonin microneedles made of PVA, sodium carboxymethylcellulose and dextran

[0040] Prepare the mixed solution of PVA solution and sodium carboxymethyl cellulose and dextran respectively;

[0041] Mix the mixed solution of melatonin, PVA solution, sodium carboxymethylcellulose and dextran, wherein the solid content of PVA accounts for 11%. After pouring the mixed medicinal solution, it is poured onto a polytetrafluoroethylene mold with a microhole array, and the back of the mold is vacuumed so that the medicinal solution can be completely filled into the micropores, and then spread on the front of the mold. The upper layer is made of a backing layer made of a polymer solution. The mold and the backing layer loaded with the drug solution are frozen and thawed together for multiple times, and the microneedles and the backing layer are separated from the mold to realize the film removal. , and finally dry the microneedles to obtain the melatonin micronee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com