A dissolving device used in the production of new chemical materials

A dissolving device and new material technology, applied in the direction of dissolving, dissolving, driving the agitator to dissolve, etc., can solve the problems of long time required for complete dissolving, great influence on dissolving speed, poor dissolving effect, etc., and achieve fast dissolving speed , fully discrete, avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

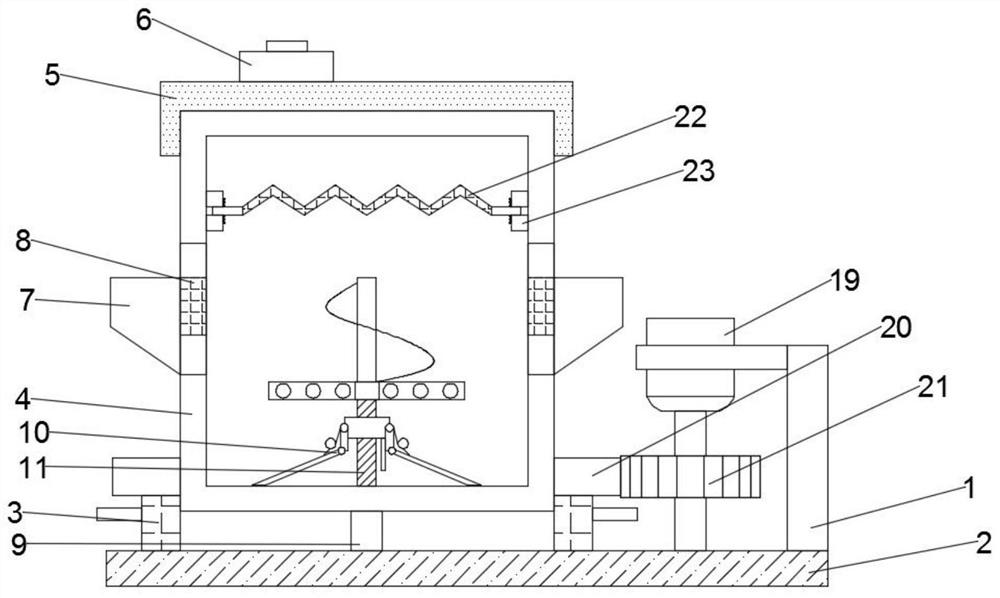

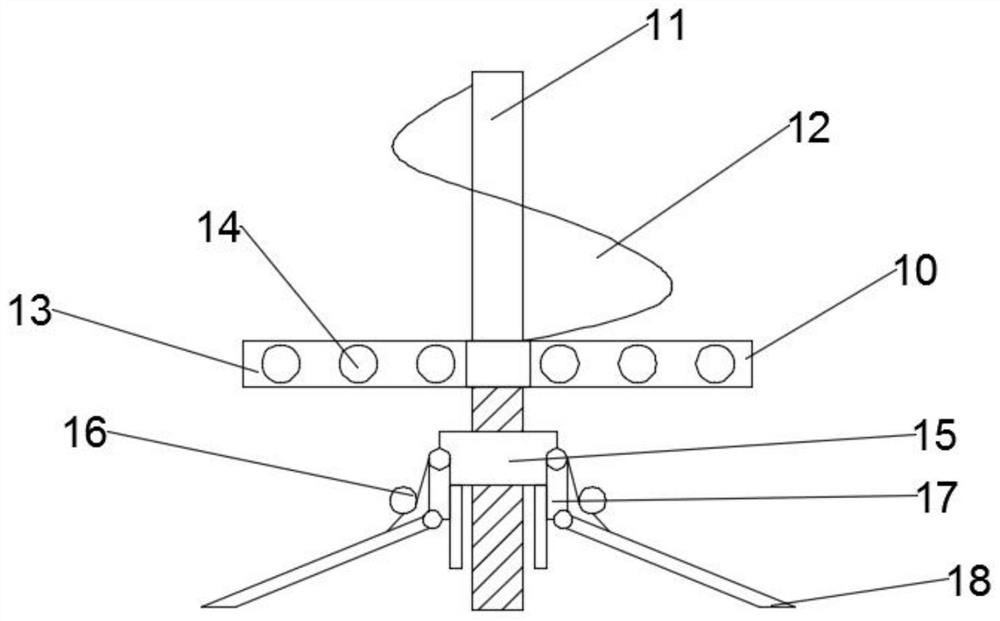

[0019] see Figure 1~2 , in this embodiment, a dissolving device used in the production of new chemical materials, comprising a support arm 1, a base 2, a dissolving tank mount 3, a dissolving tank 4 and a stirring assembly 10, the left side of the support arm 1 is fixedly installed The working motor 19, the bolt below the support arm 1 is fixedly connected to the base 2, the left side of the upper surface of the base 2 is fixedly installed with the dissolution box mounting seat 3, and the dissolution box mounting seat 3 is rotated to connect the dissolution box 4, and the dissolution box The upper edge of the cover plate 5 is clamped with the cover plate 5, and the upper surface of the cover plate 5 is provided with a material inlet 6 at the left side of the upper surface. The material inlet 6 communicates with the inner cavity of the dissolution tank 4, and a stirring assembly is installed inside the dissolution tank 4. 10. A second filter screen 22 is arranged above the sti...

Embodiment 2

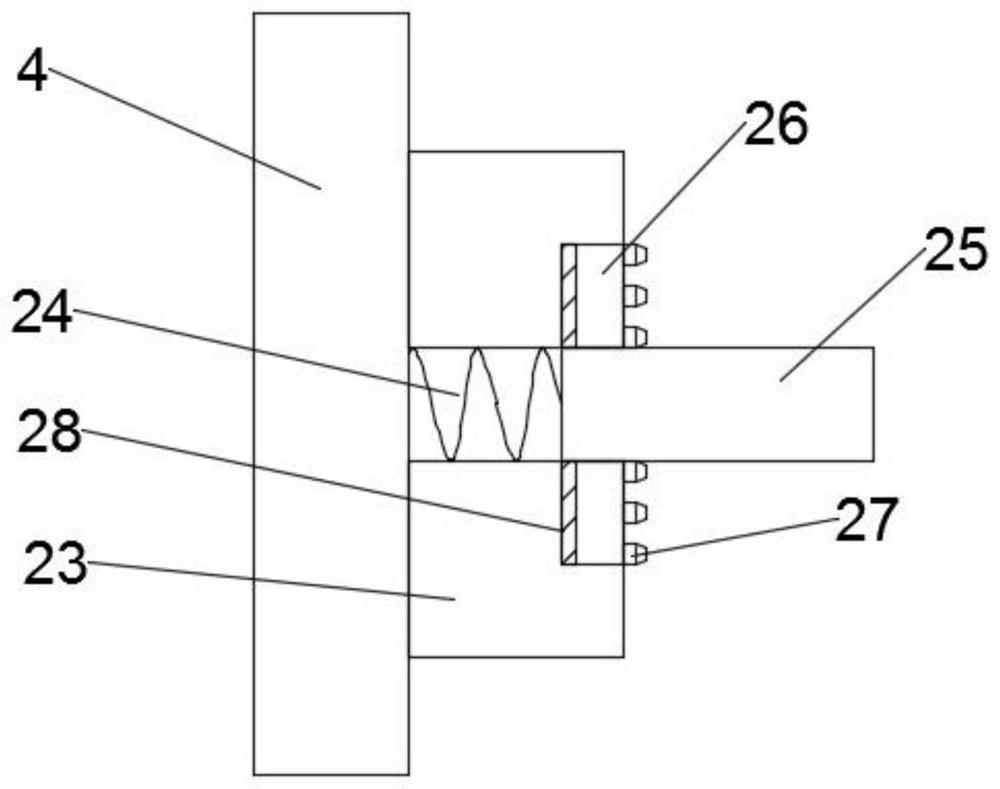

[0027] see Figure 3-4 , in this embodiment, the connection mode between the connecting rod 25 and the buffer seat 23 is a sliding connection, a chute is provided in the middle of the buffer seat 23, and the connecting rod 25 is placed in the chute, the connection A buffer spring 24 is clamped between one end of the rod 25 away from the second filter screen 22 and the side wall of the chute, and the buffer spring 24 has the effect of buffering and protecting the second filter screen 22, and the connecting rod 25 is far away from the One end of the second filter screen 22 welds the piston plate 28 up and down, two air release cavities 26 are installed symmetrically about the draw-in groove in the buffer seat 23, the piston plate 28 is arranged in the air release cavity 26, and the piston plate 28 is connected to the air release cavity 26. The air release chamber 26 is slidingly connected, and the air release chamber 26 is far away from the side wall of the dissolution box 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com