Heterocyclic aromatic compound substituted phosphine palladium sulfonate and nickel catalyst, ligand, preparation method and uses thereof

A technology for alkanes and alkenes, applied in the field of preparation, palladium phosphine sulfonate and nickel catalysts substituted by heterocyclic aromatic hydrocarbons and their ligands, which can solve the problem of low insertion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

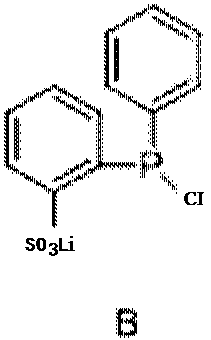

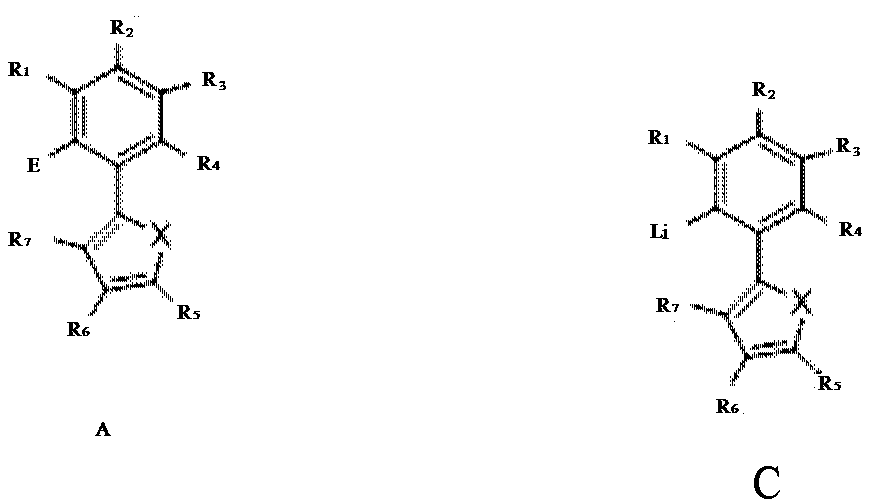

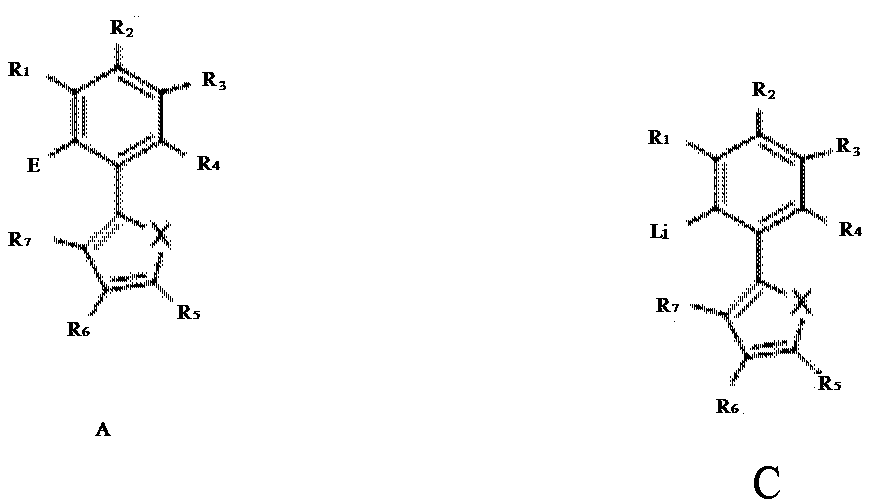

[0065] Example 1: 2-((2-furylphenyl)(phenyl)phosphino)benzenesulfonic acid

[0066]

[0067] Benzenesulfonic acid (1.58 g, 10 mmol) was dissolved in 25 ml of tetrahydrofuran solution, and 8 ml of n-butyllithium (concentration: 2.5 mol / L, 20 mmol) was slowly added dropwise at 0°C for 1 hour of reaction. Dissolve 10 mmoles of phenylphosphine dichloride in 25 ml of tetrahydrofuran solution and place it at minus 78°C, then slowly add tetrahydrofuran solution of lithium benzenesulfonate, and react at room temperature for 2 hours to obtain mixed solution A. 1-Bromo-2-furanbenzene (2.2 g, 10 mmol) was dissolved in 20 ml of tetrahydrofuran under nitrogen protection, cooled to minus 78°C, and 4 ml of n-butyllithium (concentration of 2.5 moles per liter, 10 millimoles), and reacted for 1 hour at minus 78°C. The mixed solution A was added thereto at minus 78°C, and reacted at room temperature for 24 hours. The solvent was spin-dried, and the residue was dissolved in water. The aqueo...

Embodiment 2

[0068] Example 2: 2-((2-benzofurylphenyl)(phenyl)phosphino)benzenesulfonic acid

[0069]

[0070] The synthesis procedure was the same as above, and 1-bromo-2-benzofuranbenzene (2.72 g, 10 mmol) was added to obtain a white solid (3.3 g, 72% yield). 1H NMR (400MHz, CDCl3): δ 8.43(br, 1H), 7.97(br, 1H), 7.78(d, J=5.9Hz, 2H), 7.57-7.48(m, 8H), 7.37-7.35(d, J=7.6Hz 2H), 7.20-7.19(d, J=7.3Hz, 2H), 7.10(s, 2H).13C NMR(100MHz, DMSO) of L2: δ153.9(s), 151.8(s), 151.6(s), 138.3(d, JPC=13Hz), 137.2(s), 137.0(s), 135.0(d, JPC=11Hz), 134.3(s), 134.1(s), 133.8(s), 133.6( s), 133.4(s), 133.2(s), 129.6(s), 129.2(d, JPC=6Hz), 128.8(s), 128.6(s), 128.4(s), 128.3(s), 127.7(s ), 124.8(s), 123.1(s), 121.6(s), 111.2(s), 108.1(d, JPC=18Hz).31P NMR(162MHz, DMSO): δ-13.82.ESI-MS(m / z ): [M-H] - calculated for C26H18O4 PS, 457.0663; found: 457.0656.

Embodiment 3

[0071] Example 3: 2-((2-benzothiophenephenyl)(phenyl)phosphino)benzenesulfonic acid

[0072]

[0073] The synthesis procedure was the same as above, and 1-bromo-2-benzothiophenebenzene (2.88 g, 10 mmol) was added to obtain a white solid (3.8 g, 80% yield). 1H NMR (400MHz, CDCl3): δ 8.41(br, 1H), 7.77(br, 3H), 7.67(br, 3H), 7.56(br, 1H), 7.74-7.28(m, 9H), 7.12(br, 1H).13C NMR (100MHz, DMSO) of L3: δ151.76(d, J=26.3Hz), 149.62(d, J=7.1Hz), 142.27(d, J=4.8Hz), 140.81(d, J =4.1Hz), 140.03(s), 139.32(m), 138.48(m), 137.42(d, J=7.1Hz), 134.86(d, J=8.7Hz), 134.22 (d, J=11.4Hz), 133.48(dd, J=31.3, 9.8Hz), 132.78(d, J=9.7Hz), 132.20(t, J=27.7Hz), 131.41(d, J=8.5Hz), 130.79(s), 129.02(m ), 128.65(m), 128.35(d, J=5.8Hz), 128.64(m), 126.39(s), 125.33(d, J=12.0Hz), 124.35(d, J=10.9Hz), 123.80(s ), 121.87 (d, J=13.6Hz).31P NMR (162MHz, CDCl3): δ2.04.ESI-MS (m / z): [M-H]-calculated C26H18O3PS2, 473.660435;

[0074] Measured: 473.0417.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap