Sodium alginate-modified blasting bead composite film for cigarettes and preparation method thereof

A sodium alginate and composite film technology, which is applied in the field of cigarette additives, can solve the problems that the popping technology cannot satisfy the production and the diversified development of popping balls, and achieve the effects of compact structure, good film-forming property, and enhanced plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

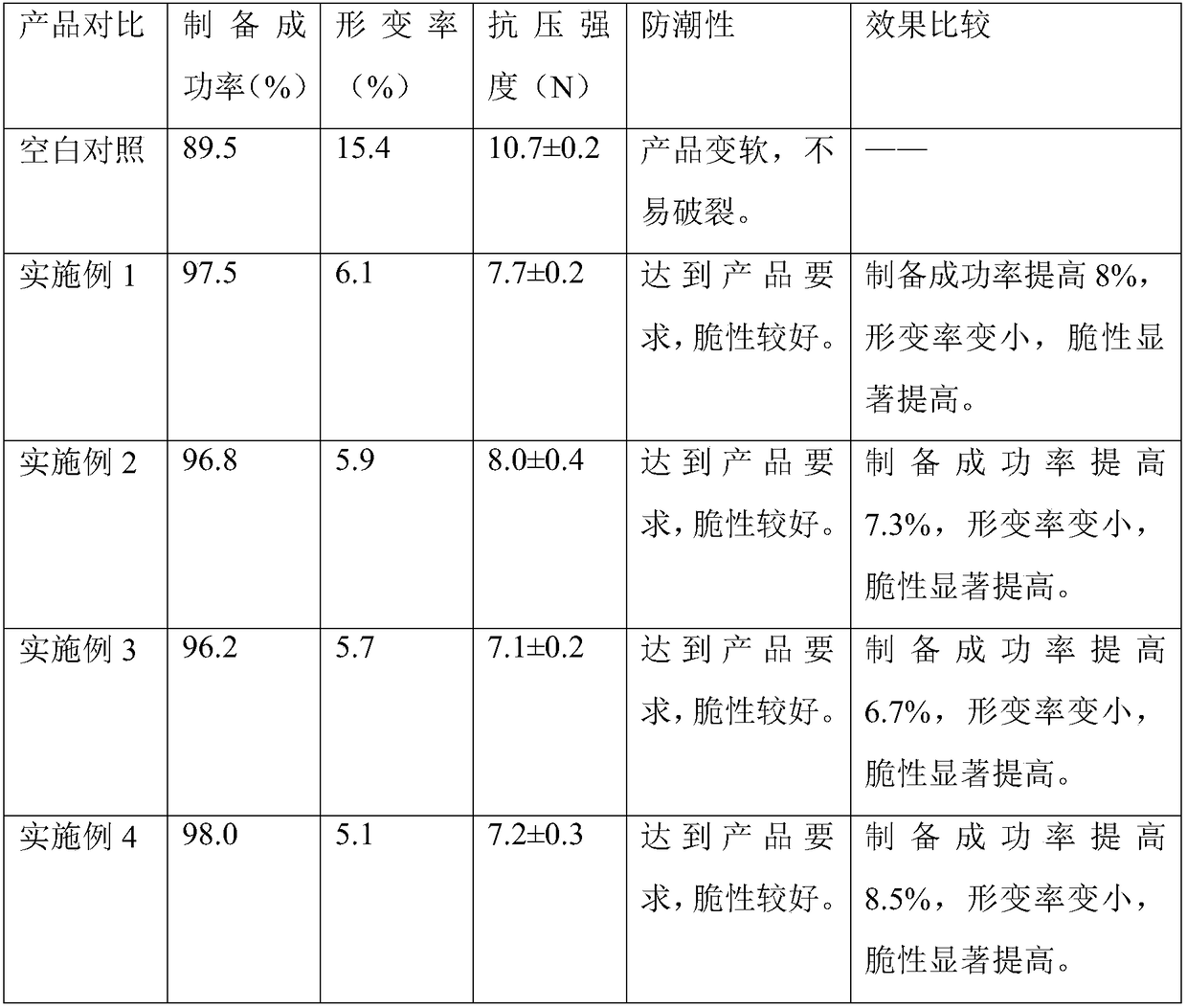

Examples

Embodiment 1

[0025] A sodium alginate modified pop-ball composite film for cigarettes, comprising various components according to the following proportions by weight: 80 parts of sodium alginate, 18 parts of pomelo peel pectin, 5 parts of carrageenan, 1 part of glycerin, 2 parts of NaCl, 150 parts of tap water. Its concrete preparation steps are as follows:

[0026] 1. Prepare 80 parts of sodium alginate and 18 parts of pomelo peel pectin into uniform colloidal aqueous solution;

[0027] 2. After fully mixing the sodium alginate aqueous solution and the pomelo peel pectin aqueous solution, slowly add 5 parts of carrageenan to it, stir well and dissolve evenly;

[0028] 3. Slowly add 1 part of glycerin to it after fully dissolved;

[0029] 4. Add 2 parts of NaCl, after fully stirring and dissolving, carry out degassing treatment under reduced pressure, and then the production and preparation of popping beads for cigarettes can be carried out.

[0030] 5. The prepared popping beads are te...

Embodiment 2

[0032] A sodium alginate modified pop-ball composite film for cigarettes, comprising various components according to the following proportions by weight: 90 parts of sodium alginate, 15 parts of apple pectin, 10 parts of gum arabic, and 2 parts of sorbitol , 2 parts of KCl, 160 parts of tap water. Its concrete preparation steps are as follows:

[0033] 1. 90 parts of sodium alginate and 15 parts of apple pectin were prepared into uniform colloidal aqueous solution;

[0034] 2. After fully mixing the sodium alginate aqueous solution and the pomelo peel pectin aqueous solution, slowly add 5 parts of gum arabic to it, stir well and dissolve evenly;

[0035] 3. Slowly add 1 part of sorbitol to it after fully dissolved;

[0036] 4. Add 2 parts of KCl, and after fully stirring and dissolving, carry out degassing treatment under reduced pressure, and then the production and preparation of popping beads for cigarettes can be carried out.

[0037] 5. The prepared popping beads are t...

Embodiment 3

[0039] A sodium alginate modified pop-pop composite film for cigarettes, comprising various components according to the following proportions by weight: 80 parts of sodium alginate, 16 parts of orange peel pectin, 6 parts of xanthan gum, and 3 parts of manna Sugar alcohol, 1 part CaCl 2 , 165 parts of tap water. Its concrete preparation steps are as follows:

[0040] 1. Prepare 80 parts of sodium alginate and 16 parts of orange peel pectin into uniform colloidal aqueous solution;

[0041] 2. After fully mixing the sodium alginate aqueous solution and the pomelo peel pectin aqueous solution, slowly add 6 parts of xanthan gum to it, stir well and dissolve evenly;

[0042] 3. Slowly add 3 parts of mannitol to it after fully dissolved;

[0043] 4. Add 1 part of CaCl 2 , after fully stirring and dissolving, carry out degassing treatment under reduced pressure, and then the production and preparation of popping beads for cigarettes can be carried out.

[0044] 5. The prepared p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com