Preparation method of inner wall putty with humidity regulation function

A kind of interior wall putty and functional technology, applied in the direction of filling slurry, etc., can solve the problems of poor humidity control performance, achieve the effect of improving quality, enhancing humidity control ability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

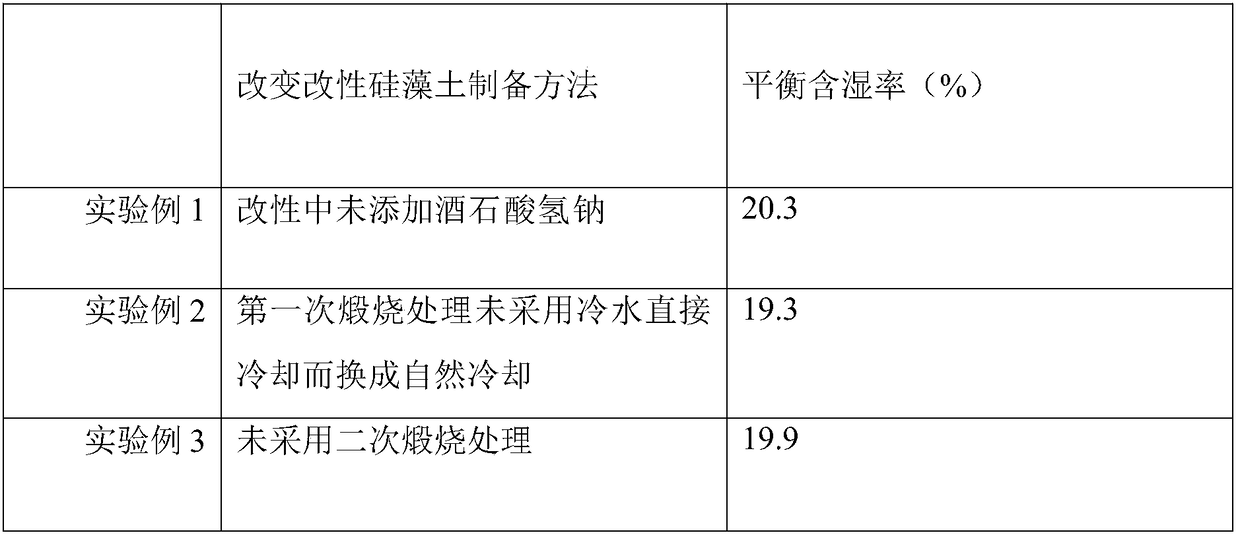

Examples

Embodiment 1

[0025] A kind of preparation method of interior wall putty with humidity control function of the present embodiment, comprises the following steps:

[0026] Step 1, weigh the following raw materials by weight: 42 parts of white cement, 12 parts of admixture, 14 parts of modified diatomite, 6 parts of stilbite, 5 parts of silica fume, 3 parts of steel slag powder, hollow medium silica micro 4 parts of balls, 3 parts of activated carbon, 2 parts of oyster shell powder, 0.2 parts of active stimulating agent, 12 parts of deionized water;

[0027] Step 2, white cement, admixture, modified diatomite, stilbite, silica fume, steel slag powder, hollow medium silica microspheres, activated carbon, oyster shell powder, active stimulator in step 1, first Stir at a high speed of 215r / min for 35 minutes, then add deionized water, stir at a low speed of 75r / min, and stir for 15 minutes to obtain the interior wall putty of the present invention.

[0028] The white cement density of present e...

Embodiment 2

[0037] A kind of preparation method of interior wall putty with humidity control function of the present embodiment, comprises the following steps:

[0038] Step 1, weigh the following raw materials by weight: 48 parts of white cement, 20 parts of admixture, 18 parts of modified diatomite, 10 parts of stilbite, 9 parts of silica fume, 5 parts of steel slag powder, hollow medium silica micro 8 parts of balls, 5 parts of activated carbon, 5 parts of oyster shell powder, 0.8 parts of active stimulating agent, 18 parts of deionized water;

[0039] Step 2, white cement, admixture, modified diatomite, stilbite, silica fume, steel slag powder, hollow medium silica microspheres, activated carbon, oyster shell powder, active stimulator in step 1, first Stir at a high speed of 225r / min for 45min, then add deionized water and stir at a low speed of 85r / min for 25min to obtain the interior wall putty of the present invention.

[0040] The white cement density of the present embodiment is...

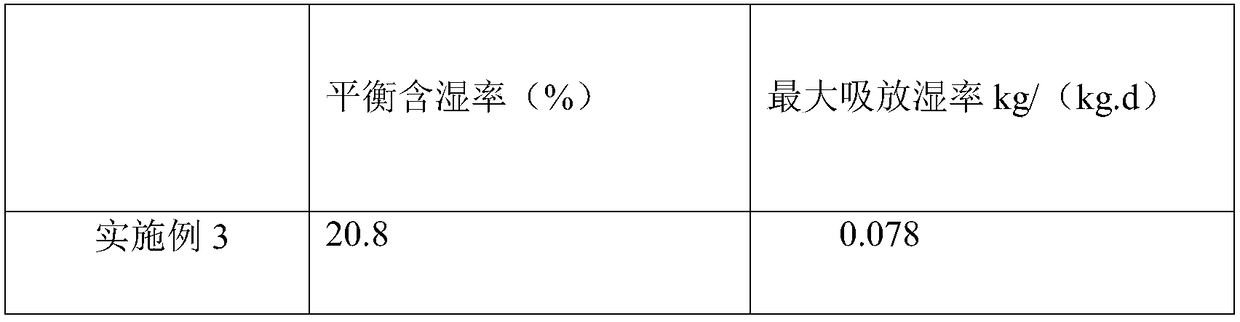

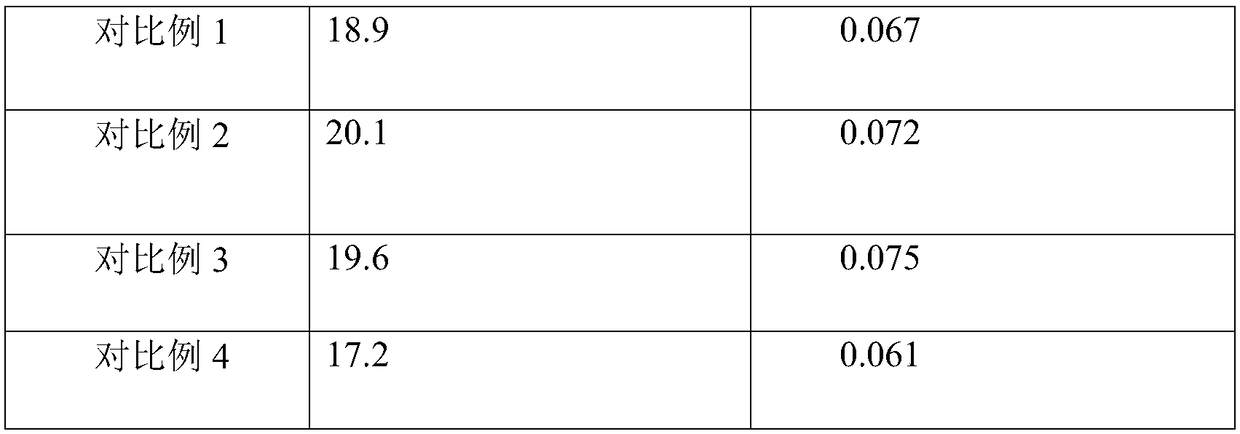

Embodiment 3

[0049] A kind of preparation method of interior wall putty with humidity control function of the present embodiment, comprises the following steps:

[0050] Step 1, weigh the following raw materials by weight: 45 parts of white cement, 16 parts of admixture, 16 parts of modified diatomite, 8 parts of stilbite, 7 parts of silica fume, 4 parts of steel slag powder, hollow medium silica micro 6 parts of balls, 4 parts of activated carbon, 3.5 parts of oyster shell powder, 0.5 parts of active stimulating agent, 15 parts of deionized water;

[0051] Step 2, white cement, admixture, modified diatomite, stilbite, silica fume, steel slag powder, hollow medium silica microspheres, activated carbon, oyster shell powder, active stimulator in step 1, first Stir at a high speed of 220r / min for 40min, then add deionized water and stir at a low speed of 80r / min for 20min to obtain the interior wall putty of the present invention.

[0052] The white cement density of present embodiment is 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com