Waterproof ink for packaging and printing and preparation method thereof

A packaging printing and ink technology, applied in ink, applications, household appliances, etc., can solve the problems of poor water resistance of ink, easy scratches of patterns, easy delamination of ink, etc., to improve connectivity and compatibility , improve wear resistance, improve the effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

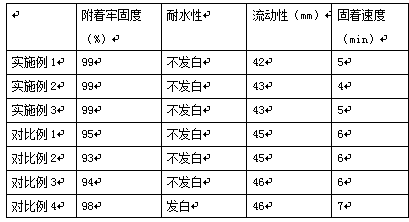

Examples

Embodiment 1

[0025] A waterproof ink for packaging and printing, the components are as follows in parts by weight: 12 parts of maleic acid resin, 10 parts of water-soluble acrylic resin, 7 parts of carboxymethyl cellulose, 5 parts of ethyl acetate, 25 parts of isopropanol 2 parts, 2 parts of stabilizer, 1 part of leveling agent, 1 part of defoamer, 2 parts of dispersant, 3 parts of water repellent, 2 parts of slip agent, 3 parts of pigment, 4 parts of xanthan gum, 5 parts of gum arabic, 3 parts of fine-pore silica gel.

[0026] Preferably, the stabilizer is composed of hydroquinone and p-methoxyphenol in a weight ratio of 1:2.

[0027] Preferably, the leveling agent is composed of isophorone and diacetone alcohol in a weight ratio of 1:1.

[0028] Preferably, the defoamer is composed of emulsified silicone oil, polydimethylsiloxane, and higher alcohol fatty acid ester compound in a weight ratio of 1:1:1.5.

[0029] Preferably, the dispersant is composed of paraffin wax and calcium steara...

Embodiment 2

[0041] A waterproof ink for packaging and printing, the components are as follows in parts by weight: 15 parts of maleic acid resin, 12 parts of water-soluble acrylic resin, 10 parts of carboxymethyl cellulose, 7 parts of ethyl acetate, 27 parts of isopropanol 2 parts, 2 parts of stabilizer, 1 part of leveling agent, 2 parts of defoamer, 2 parts of dispersant, 3 parts of water repellent, 3 parts of slip agent, 3 parts of pigment, 5 parts of xanthan gum, 6 parts of gum arabic, 4 parts of fine-pore silica gel.

[0042] Preferably, the stabilizer is composed of hydroquinone and p-methoxyphenol in a weight ratio of 1:2.

[0043] Preferably, the leveling agent is composed of isophorone and diacetone alcohol in a weight ratio of 1:1.

[0044] Preferably, the defoamer is composed of emulsified silicone oil, polydimethylsiloxane, and higher alcohol fatty acid ester compound in a weight ratio of 1:1:1.5.

[0045] Preferably, the dispersant is composed of paraffin wax and calcium stea...

Embodiment 3

[0057] A waterproof ink for packaging and printing, the components are as follows in parts by weight: 17 parts of maleic acid resin, 15 parts of water-soluble acrylic resin, 13 parts of carboxymethyl cellulose, 8 parts of ethyl acetate, 30 parts of isopropanol 3 parts, 3 parts of stabilizer, 2 parts of leveling agent, 3 parts of defoamer, 3 parts of dispersant, 4 parts of water repellent, 4 parts of slip agent, 4 parts of pigment, 6 parts of xanthan gum, 7 parts of gum arabic, 5 parts of fine-pore silica gel.

[0058] Preferably, the stabilizer is composed of hydroquinone and p-methoxyphenol in a weight ratio of 1:2.

[0059] Preferably, the leveling agent is composed of isophorone and diacetone alcohol in a weight ratio of 1:1.

[0060] Preferably, the defoamer is composed of emulsified silicone oil, polydimethylsiloxane, and higher alcohol fatty acid ester compound in a weight ratio of 1:1:1.5.

[0061] Preferably, the dispersant is composed of paraffin wax and calcium ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com