Glazing oil and preparation method thereof

A technology of parts by weight and emulsifier, applied in the direction of coating, etc., can solve the problem of uneven surface thickness, etc., and achieve the effects of enhancing leveling, emulsifying effect, and improving surface hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: a kind of varnish, including the components shown in Table 1 in parts by weight.

[0052] The above-mentioned high-strength impermeable concrete is prepared through the following steps:

[0053] S1, take the emulsifier and water in corresponding parts by weight, heat in a water bath to 80° C. to dissolve, and stir at high speed to obtain an emulsified solution. Take corresponding parts by weight of methyl methacrylate, butyl acrylate, acrylic acid, acrylonitrile and hydroxyethyl acrylate, mix them uniformly, add them into the emulsified solution, and mix them uniformly to obtain a seed emulsion.

[0054] S2, taking corresponding parts by weight of polyvinyl alcohol powder and initiator and mixing to obtain an additive liquid. Take 20% of the seed emulsion, add 1 / 3 of the additive solution, mix evenly to obtain a reaction solution, and control the reaction temperature at 80°C. After the reaction solution turns blue, add the remaining seed emulsion and the...

Embodiment 2-7

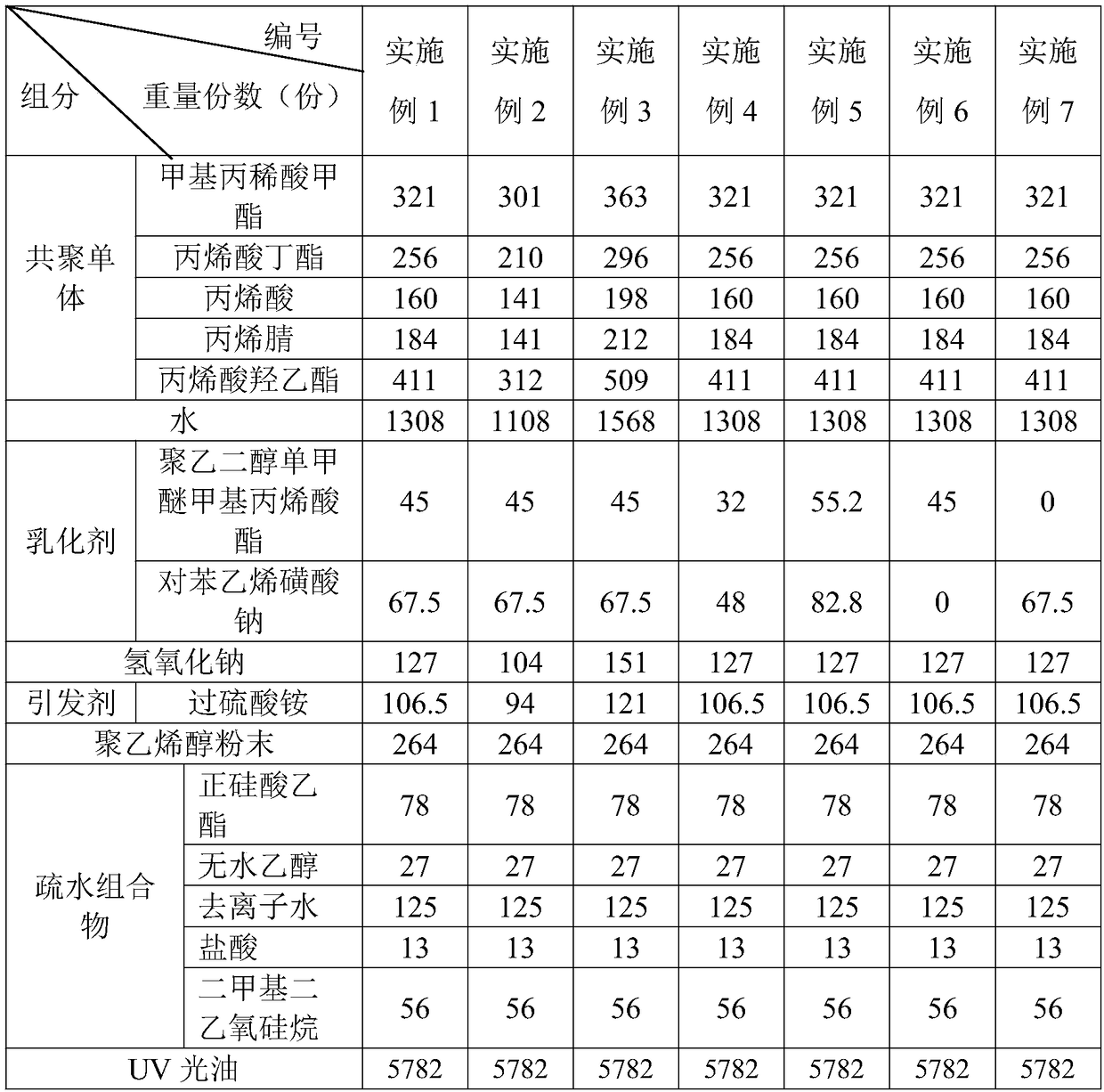

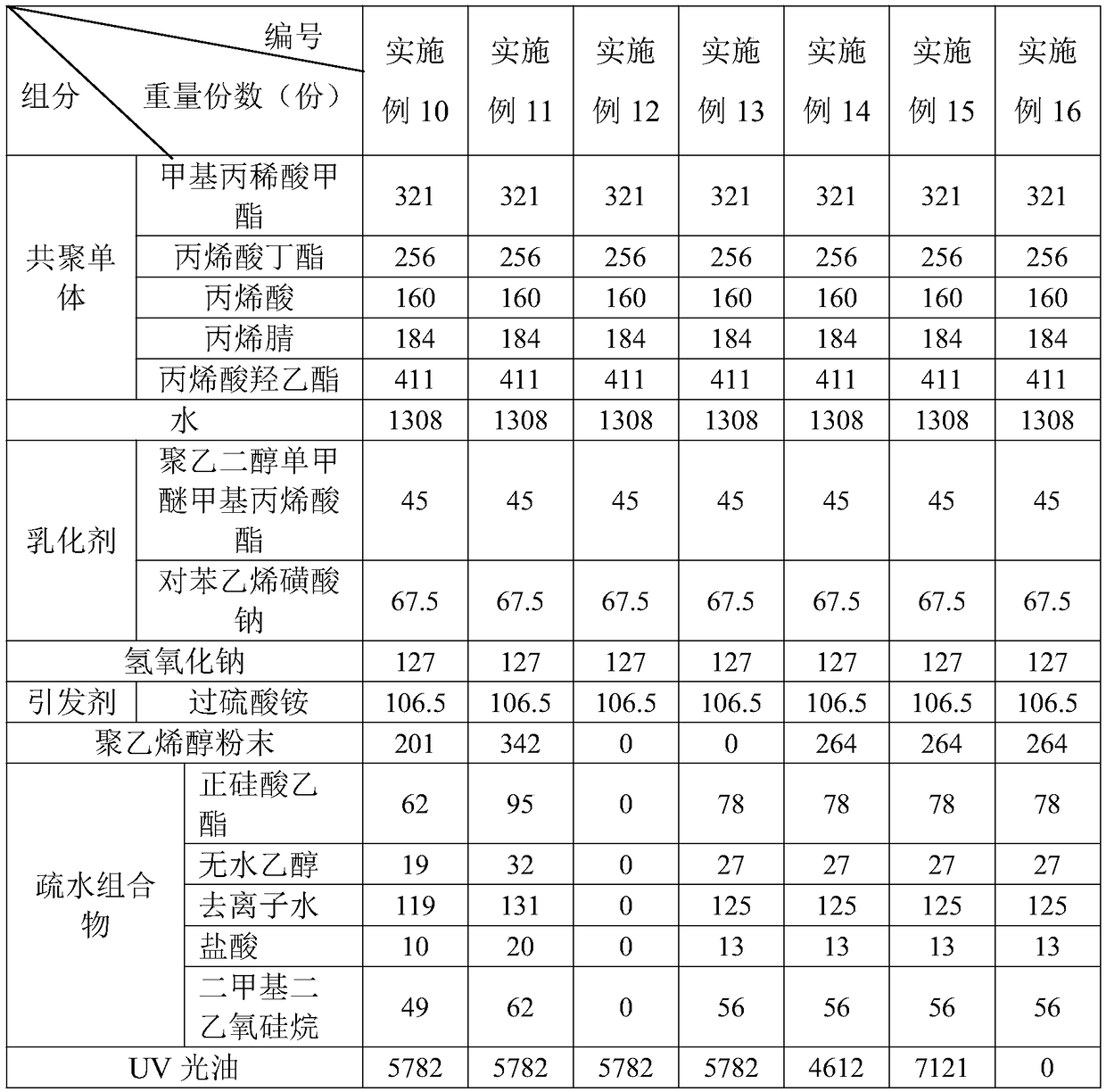

[0057]Embodiment 2-7: a kind of glazing oil, the only difference from embodiment 1 is that the parts by weight of some components are different; the components and parts by weight are shown in Table 1.

[0058] Components and their corresponding parts by weight in table 1. embodiment 1-7

[0059]

Embodiment 8-9

[0060] Embodiment 8-9: A kind of glazing oil, the only difference from Embodiment 1 is that polyethylene glycol monomethyl ether methacrylate with relative molecular weights of 1000 and 1200 are selected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com