Preparation method of Ni2P2O7 film

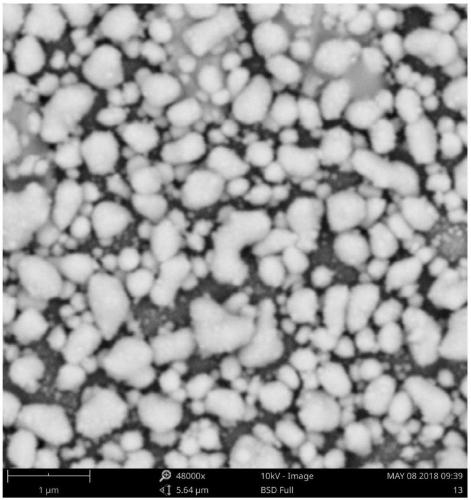

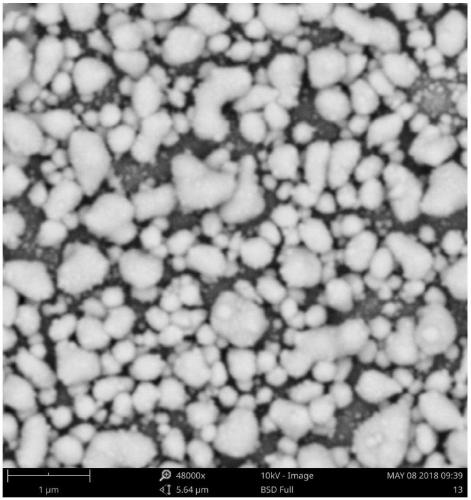

A thin film and electrolyte technology, applied in the field of Ni2P2O7 thin film preparation, can solve the problems of lack of thin film preparation methods and less research, and achieve the effect of good surface smoothness and good surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

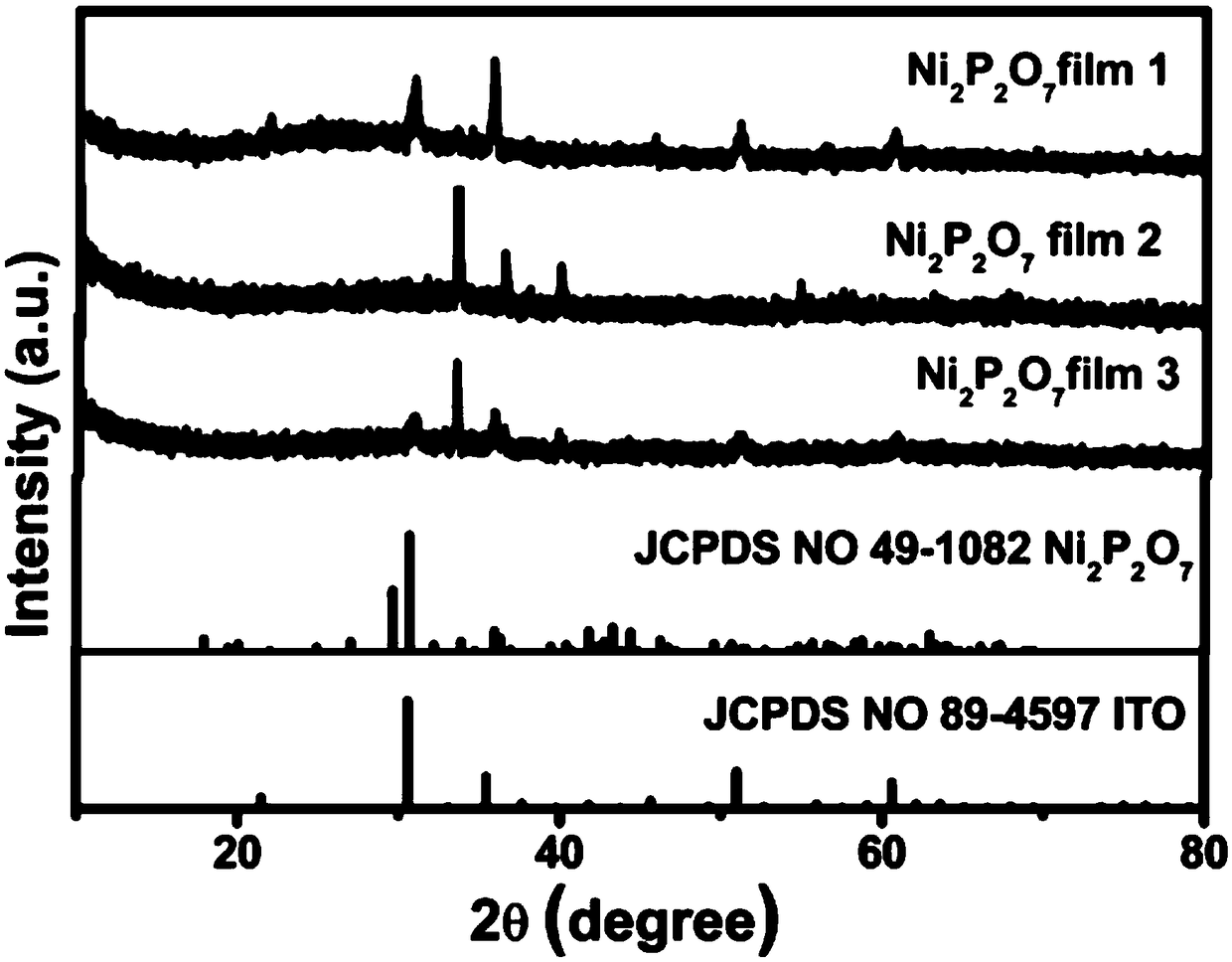

[0030] A kind of Ni 2 P 2 o 7 The preparation method of the thin film adopts standard three-electrode cyclic voltammetry to deposit on the surface of ITO,

[0031] The electrolyte and concentration of the electrolyte used are: 0.1mmol / L NaH 2 PO 2 , 0.2mmol / L C 6 h 5 Na 3 o 7 and 5mmol / L NiSO 4 ;

[0032] A platinum sheet and a silver / silver chloride (Ag / AgCl) electrode are used as counter and reference electrodes;

[0033] The deposition process is carried out in the range of -1~0V, the temperature of the electrolyte is 42°C, and the scanning speed is 20 mVs -1 . The scanning cycle is 15r.

Embodiment 2

[0035] A kind of Ni 2 P 2 o 7 The preparation method of the thin film adopts standard three-electrode cyclic voltammetry to deposit on the surface of ITO,

[0036] The electrolyte and concentration of the electrolyte used are: 0.5mmol / L NaH 2 PO 2 , 0.1 mmol / L C 6 h 5 Na 3 o 7 and 0.2 mmol / L NiSO 4 ;

[0037] A platinum sheet and a silver / silver chloride (Ag / AgCl) electrode are used as counter and reference electrodes;

[0038] The deposition process is carried out in the range of -1.5~0V, the temperature of the electrolyte is 48°C, and the scanning speed is 20 mVs -1 . The scanning cycle is 20r.

Embodiment 3

[0040] A kind of Ni 2 P 2 o 7 The preparation method of the thin film adopts standard three-electrode cyclic voltammetry to deposit on the surface of ITO,

[0041] The electrolyte and concentration of the electrolyte used are: 0.2mmol / L NaH 2 PO 2 , 0.5mmol / L C 6 h 5 Na 3 o 7 and 1mmol / L NiSO 4 ;

[0042] A platinum sheet and a silver / silver chloride (Ag / AgCl) electrode are used as counter and reference electrodes;

[0043] The deposition process is carried out in the range of -0.5~0V, the temperature of the electrolyte is 45°C, and the scanning speed is 20 mVs -1 . The scanning cycle is 25r.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com