Material filling method for reducing casting monocrystal seed crystal body dislocation

A single crystal and dislocation technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems affecting the quality of cast single crystal silicon ingots, and achieve the goal of reducing bottom defects, reducing impact, and reducing dislocations the effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

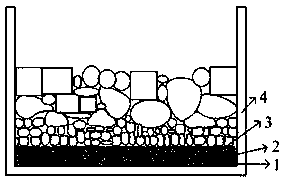

[0017] A charging method for reducing bulk dislocations in cast single crystal seed crystals, such as figure 1 As shown, the method includes the following steps:

[0018] (1) Spraying a silicon nitride coating on the inner surface of the quartz crucible 4 as a release layer for silicon ingots;

[0019] (2) Lay the first protective layer 1 on the bottom of the quartz crucible 4. The first protective layer 1 is laid in a square array of thin silicon wafers of 5*5. The size of each thin silicon wafer is 156mm*156mm*0.2mm. The lamination of thin silicon wafers is neat and seamless, without interlacing;

[0020] (3) Lay a single crystal seed layer 2 on the first protective layer 1. The single crystal seed layer 2 is formed by seamless splicing of 25 single crystal seed blocks, and the size of each single crystal seed block is 130mm *130mm*20mm, the radial direction of the single crystal seed block is [100];

[0021] (4) Lay the second protective layer 3 on the single crystal see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com