A kind of out-of-plane anisotropic garnet single crystal film and its preparation method

A single crystal thin film, anisotropic technology, applied in the field of out-of-plane anisotropic garnet thin film and its liquid phase epitaxy preparation field, can solve the problem of difficult to prepare garnet thin film and the like, achieve good lattice constant and good matching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

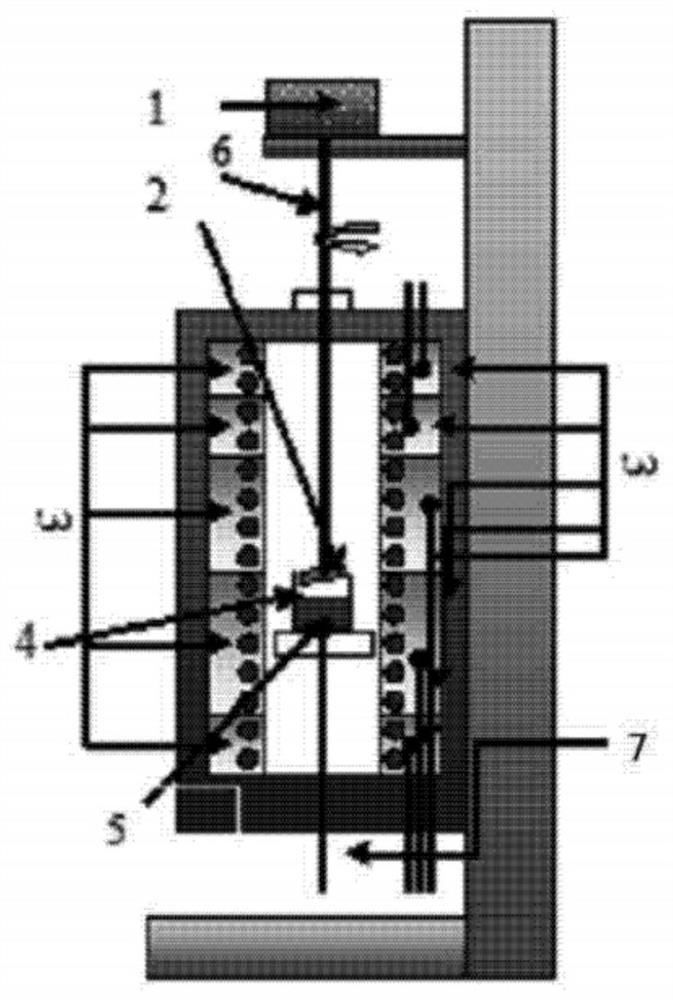

[0023] Method for preparing an anisotropic garnet single crystal film, including the following steps:

[0024] Step 1, the prime material weigh: in y 2 O 3 , Lu 2 O 3 , Fe 2 O 3 GEO 2 , Cao, Pbo, BI 2 O 3 MOO 3 For the raw material, accurately weigh the above raw materials, where Y 2 O 3 , Lu 2 O 3 , Fe 2 O 3 GEO 2 , Cao, Pbo, BI 2 O 3 MOO 3The mass ratio is (0.07 ~ 0.15): (0.10 ~ 0.15): (5 ~ 7): (0.7 ~ 1): (0.1 ~ 0.15): (70 ~ 76): (10 ~ 15): (4 ~ 7) );

[0025] Step 2, the preparation of the melt: Put the raw material tiered in step 1 in the crucible, the layered sequence specifically: the first layer is a third of the PBO, the second layer is one-half of Fe 2 O 3 , 3rd floor is Y 2 O 3 , Lu 2 O 3 GEO 2 MOO 3 And one-half of the Fe 2 O 3 Mixed powder, 4th floor is one-half bi 2 O 3 The 5th floor is CAO, the 6th floor is one-half of the BI 2 O 3 The seventh layer is one-third of PBO; then heat insulation at 1000 to 1100 ° C, and after cooling to 200 ° C, the remaining one-third of...

Embodiment 1

[0029] Method for preparing an anisotropic garnet single crystal film, including the following steps:

[0030] Step 1, the prime material weigh: in y 2 O 3 , Lu 2 O 3 , Fe 2 O 3 GEO 2 , Cao, Pbo, BI 2 O 3 MOO 3 For the raw material, accurately weigh the above raw materials, where Y 2 O 3 , Lu 2 O 3 , Fe 2 O 3 GEO 2 , Cao, Pbo, BI 2 O 3 MOO 3 The mass ratio is 0.09: 0.14: 5.29: 0.85: 0.12: 75.63: 11.77: 6.11;

[0031] Step 2, the preparation of the melt: Put the raw material tiered in step 1 in the crucible, the layered sequence specifically: the first layer is a third of the PBO, the second layer is one-half of Fe 2 O 3 , 3rd floor is Y 2 O 3 , Lu 2 O 3 GEO 2 MOO 3 And one-half of the Fe 2 O 3 Mixed powder, 4th floor is one-half bi 2 O 3 The 5th floor is CAO, the 6th floor is one-half of the BI 2 O 3 The seventh layer is a third of the PBO; then heat insulation at 1050 ° C for 2 h, and after cooling to 200 ° C, the remaining one-third of the PBO is added to the crucible, and 2 h i...

Embodiment 2

[0036] Method for preparing an anisotropic garnet single crystal film, including the following steps:

[0037] Step 1, the prime material weigh: in y 2 O 3 , Lu 2 O 3 , Fe 2 O 3 GEO 2 , Cao, Pbo, BI 2 O 3 MOO 3 For the raw material, accurately weigh the above raw materials, where Y 2 O 3 , Lu 2 O 3 , Fe 2 O 3 GEO 2 , Cao, Pbo, BI 2 O 3 MOO 3 The mass ratio is 0.08: 0.14: 6.19: 0.87: 0.14: 73.15: 14.30: 5.13;

[0038] Step 2, the preparation of the melt: Put the raw material tiered in step 1 in the crucible, the layered sequence specifically: the first layer is a third of the PBO, the second layer is one-half of Fe 2 O 3 , 3rd floor is Y 2 O 3 , Lu 2 O 3 GEO 2 MOO 3 And one-half of the Fe 2 O 3 Mixed powder, 4th floor is one-half bi 2 O 3 The 5th floor is CAO, the 6th floor is one-half of the BI 2 O 3 The seventh layer is a third of the PBO; then heat insulation at 1050 ° C for 2 h, and after cooling to 200 ° C, the remaining one-third of the PBO is added to the crucible, and 2 h i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com