Goaf filling method for rock fracture development

A technology for rock mass fissures and goafs, which is used in fillings, mining equipment, earth-moving drilling, etc., can solve the problems of low overall strength of the filling body, short mixing time, difficult tailings and cement, etc. The effect of shortening and sedimentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

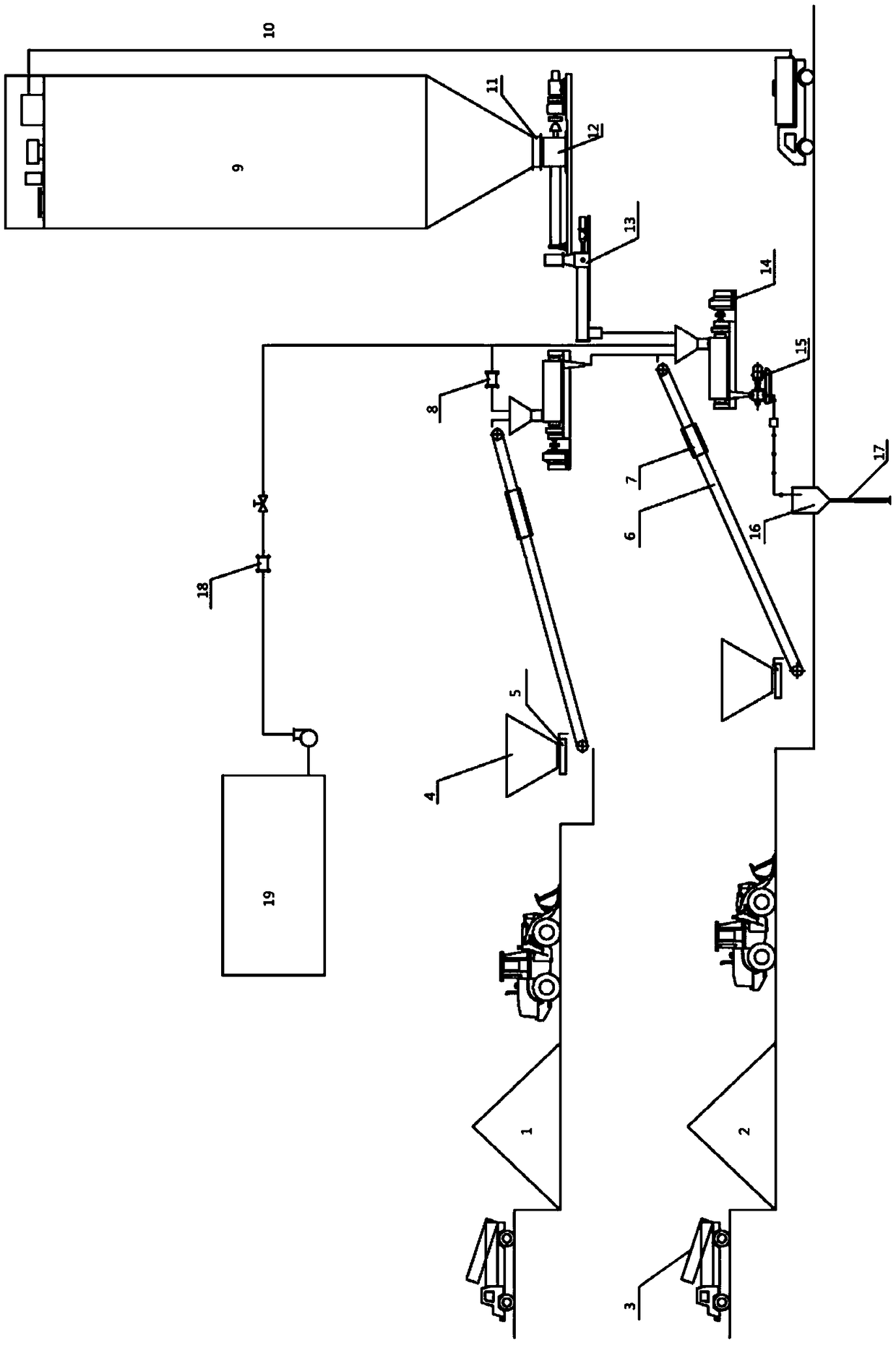

[0024] In this embodiment, because there are ore pillars left in the goaf, the ore grade is high and have relatively high economic value. The design requires that the ore pillars be returned. Impact, 425 high-grade cement is selected as the cementitious material, the whole tailing sand of the dressing plant is used as the aggregate, and the lime-sand ratio (the weight ratio of the gel agent to the sum of the weight of fine sand and coarse sand) is 1:8. The area is filled, such as figure 1 As shown, follow the steps below:

[0025] (1) Use a cyclone to classify and filter the whole tailings of the concentrator and divide them into two series of coarse sand and fine sand, put them in the dry sand storage yard, and use the dry sand batching system for batching;

[0026] (2) The gelling agent storage metering delivery system, mixing system, water storage and supply system, control system and communication command system jointly prepare the filling slurry, and the ash bin in the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com