Coke oven basement cooling ventilation equipment

A technology for ventilation equipment and basement, which is applied in the field of cooling and ventilation equipment for coke oven basement, can solve the problems such as inability to perform noise reduction treatment, inability to filter air, inability to dilute toxic gases, etc., and achieve the effects of convenient replacement, prevention of leakage, and prevention of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

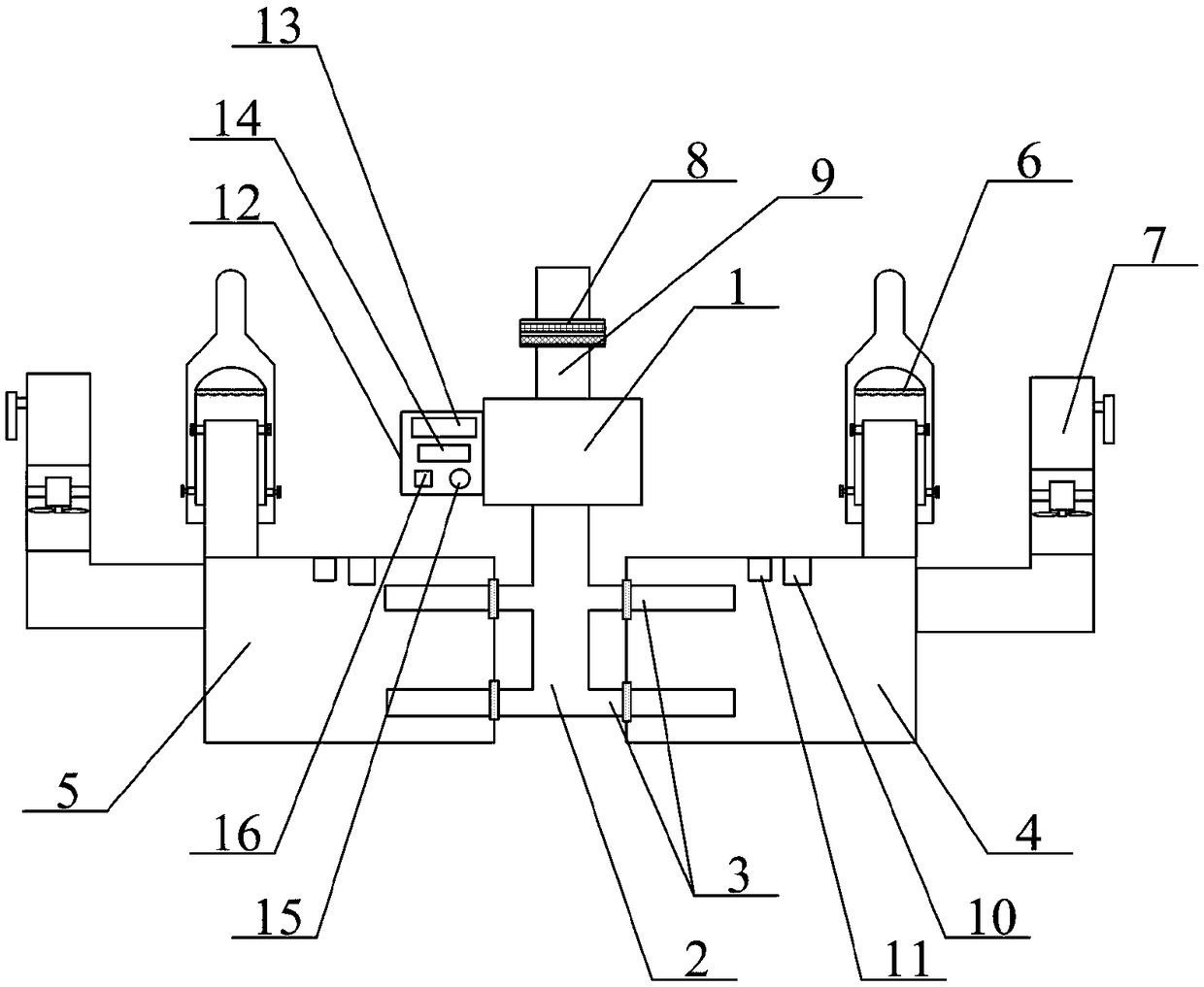

[0041] as attached figure 1 to attach Figure 5 shown

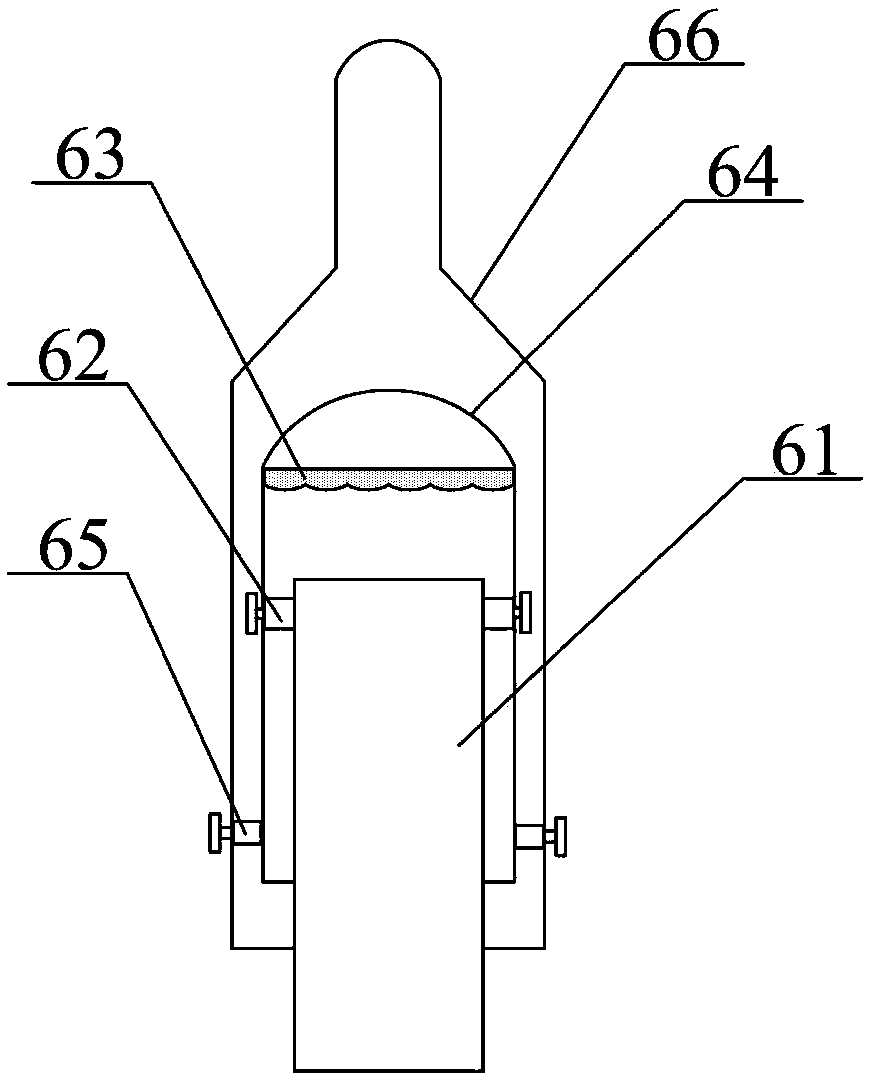

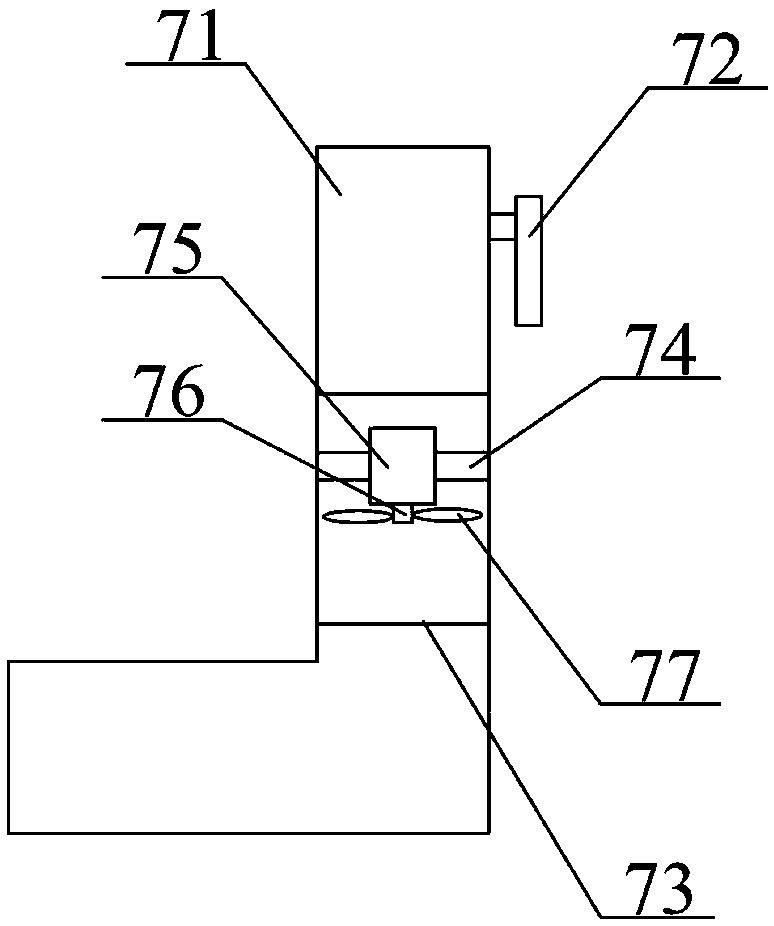

[0042]The present invention provides a coke oven basement cooling and ventilation equipment, comprising an air compressor 1, an air intake pipe 2, a shunt pipe 3, a secondary coke oven 4, a primary coke oven 5, a smoke exhaust and silencer pipe structure 6, and a sealed ventilation pipe structure 7 , air inlet filter pipe structure 8, connecting pipe 9, temperature sensor 10, air quality sensor 11, control box 12, display 13, PLC14, power indicator light 15 and switch 16, described air intake pipe 2 is welded on air compressor 1 The middle position of the lower end; the said shunt pipe 3 is respectively welded on the lower part of the left and right sides of the intake pipe 2; the said secondary coke oven 4 is arranged on the right side of the intake pipe 2; the said primary coke oven 5 It is arranged on the left side of the intake pipe 2; the smoke exhaust muffler pipe structure 6 is respectively installed on the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com