A MgIn2S4-based intermediate band solar energy absorbing material and a preparation method thereof

A solar energy absorption, mgin2s4 technology, applied in the field of new semiconductor materials, can solve the problems of low efficiency of solar cells, scarcity of intermediate band semiconductor materials, etc., and achieve the effect of increasing the electron absorption path and enhancing the light absorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] MgIn 2-x sn x S 4 Sample preparation method, specifically:

[0021] Step 1, Mg powder (4N), In particle (5N), S (5N) powder and Sn powder (4N) are according to stoichiometric ratio Mg:In:Sn:S=1:2-x:x:4(0 <x<2) After mixing evenly, vacuum seal in a quartz glass tube.

[0022] Step 2: Put the encapsulated quartz glass tube in a muffle furnace for sintering (sintering temperature is 600-750° C.), grind the obtained sample in an agate mortar and re-encapsulate in vacuum.

[0023] Step 3: Place the ground sample again in a muffle furnace for sintering for 48 hours (sintering temperature: 600-750° C.), and finally grind again to obtain the product.

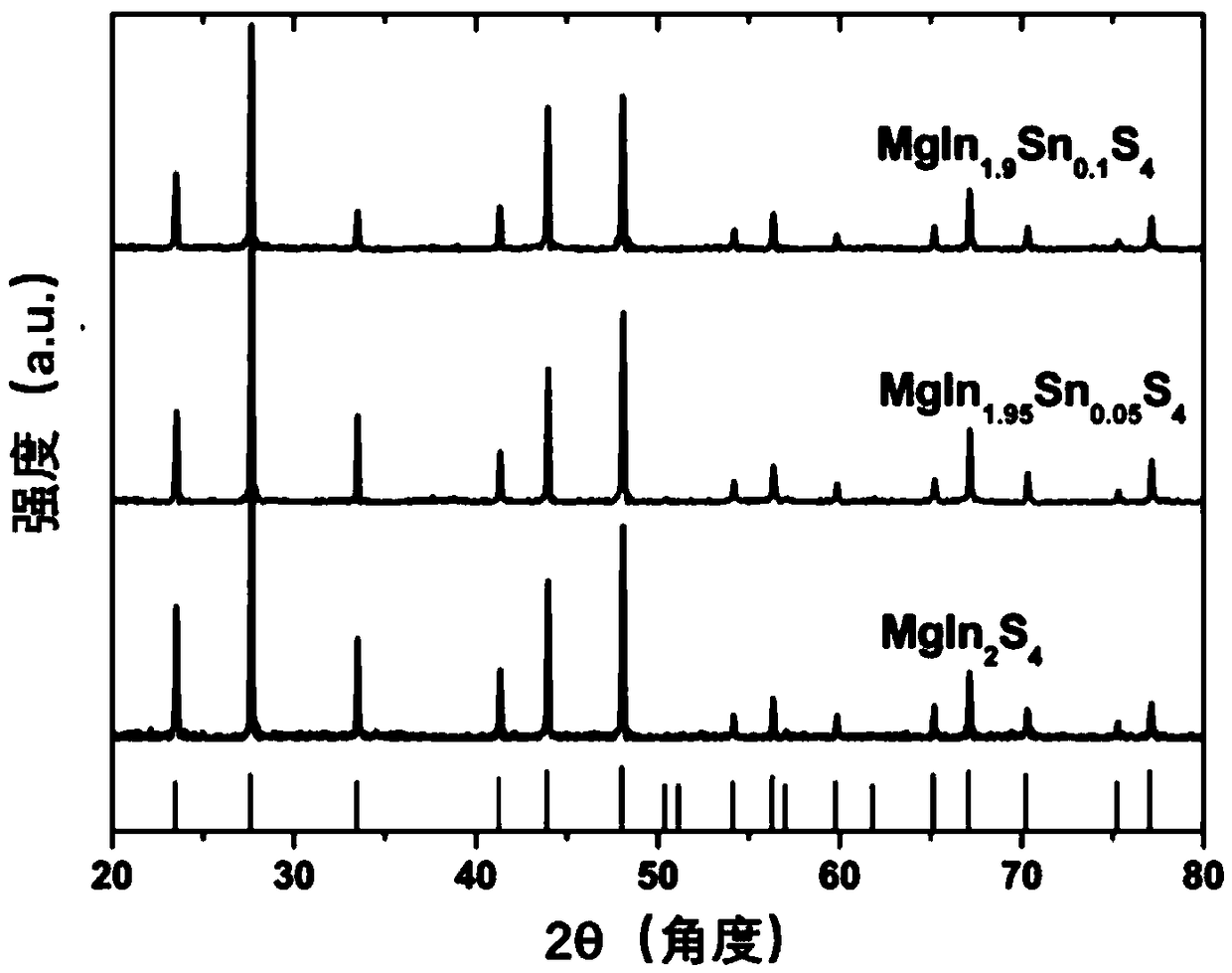

Embodiment 1-3

[0025] Prepare MgIn according to the above steps 1-3 2 S 4 、MgIn 1.9 sn 0.1 S 4 、MgIn 1.95 sn 0.05 S 4 Sample, the stoichiometric ratio of Mg powder (4N), In particle (5N), S (5N) powder and Sn powder (4N) in embodiment 1-3 is Mg:In:Sn:S=1:2-x: x:4, get x=0,0.05,0.1 respectively in embodiment 1-3; Wherein, prepare MgIn 2 S 4 For samples, the sintering temperature was 600°C, the sintering time was 48h, and the grinding time was 3min; the preparation of MgIn 1.95 sn 0.05 S 4 For samples, the sintering temperature was 700°C, the sintering time was 36h, and the grinding time was 5min; the preparation of MgIn 1.9 sn 0.1 S 4 For samples, the sintering temperature is 750°C, the sintering time is 60h, and the grinding time is 4min.

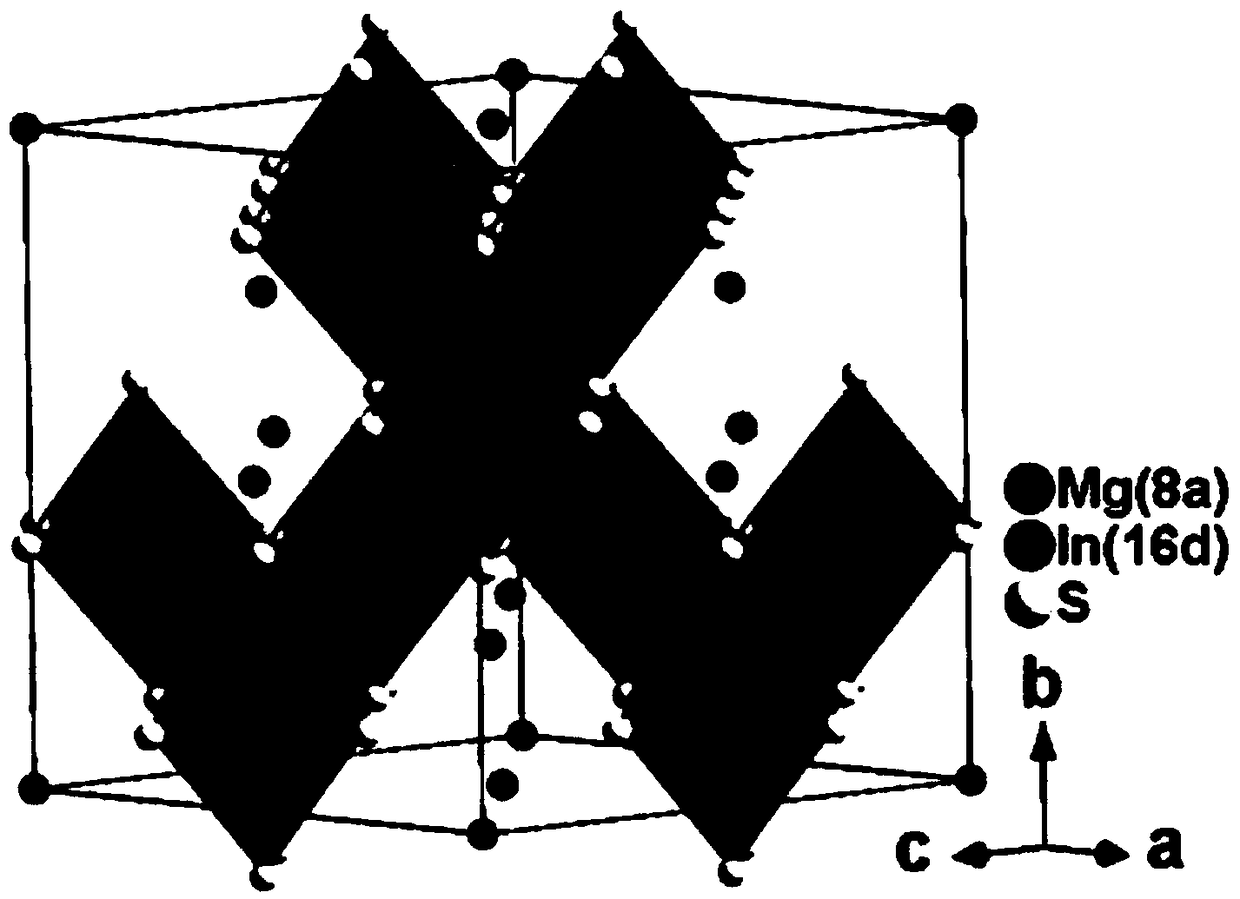

[0026] See attached figure 1 , for MgIn 2 S 4 crystal structure with an absorption coefficient of 1×10 4 -1×10 5 cm -1 , the space group is Fd-3m, and the bandgap is 2.12-2.28eV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com