A lithium ion battery separator and a preparation method thereof

A lithium-ion battery and diaphragm technology, which is applied in the field of lithium-ion battery diaphragm and its preparation, can solve the problems of large air loss, diaphragm blockage, battery capacity and performance limitations, etc., and achieve good production performance and improved dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a kind of preparation method of above-mentioned lithium-ion battery diaphragm, comprises the following steps:

[0030] Take the proportioned amount of tannic acid and deionized water, mix and stir the two, then add PVDF resin powder and stir to make a mixture, and then mix it with other components, and coat it on one or both sides of the base film.

[0031] In some embodiments, take proportioned amounts of tannic acid and deionized water, stir for 1-3 hours, and mix uniformly to obtain mixture 1;

[0032] Add a proportional amount of PVDF resin powder to the above mixture 1, stir for 2-4 hours to form a uniform and stable suspension, and obtain mixture 2;

[0033] Add a proportioned amount of thickener, defoamer, binder and wetting agent to the above mixture 2, and grind for 1-2 hours to obtain an aqueous PVDF slurry;

[0034] The above-mentioned water-based PVDF slurry is coated on one or both sides of the polyolefin base film, and ...

Embodiment 1

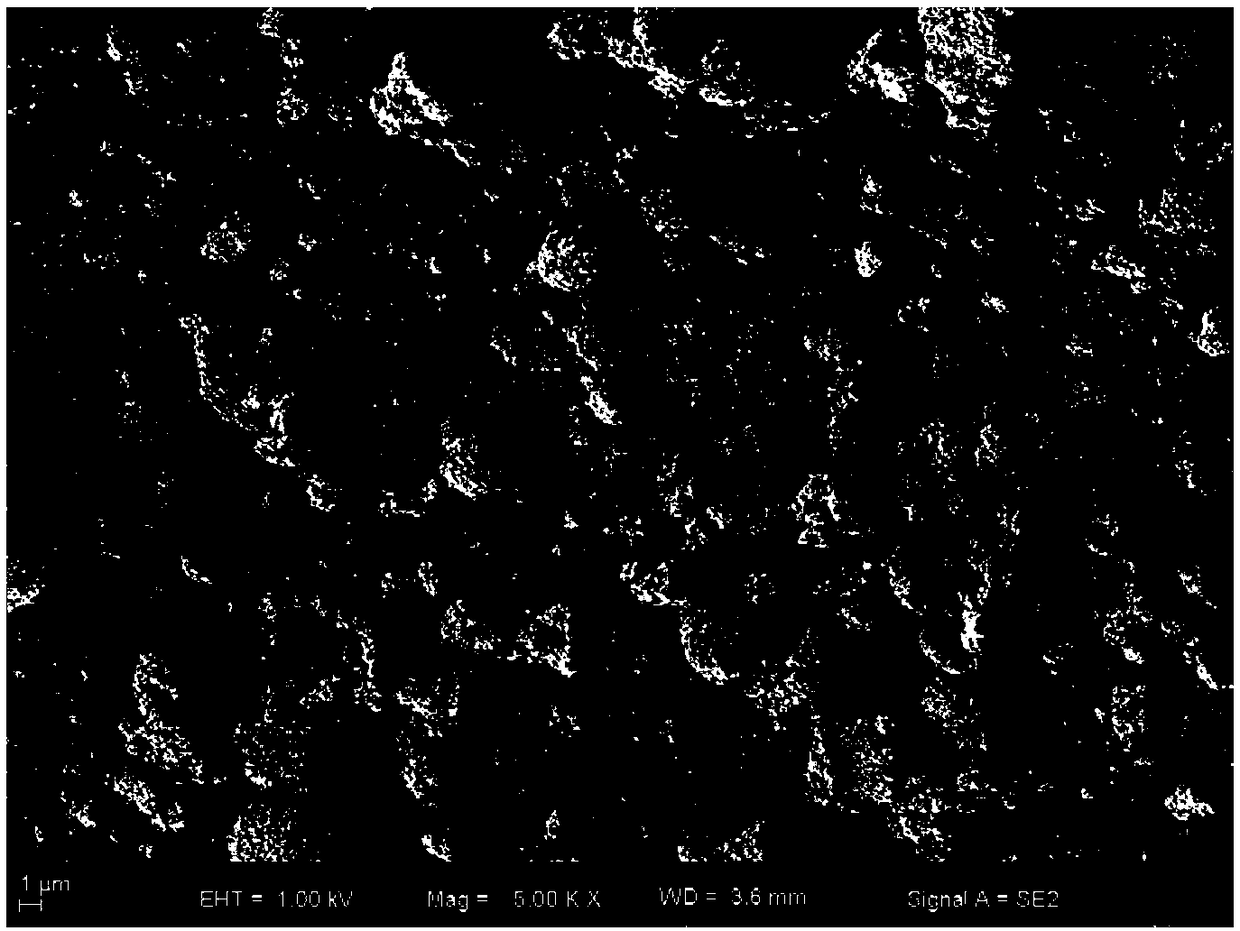

[0040] A lithium-ion battery separator, comprising a base film and a PVDF coating coated on one side or both sides of the base film, the PVDF coating is obtained by coating a water-based PVDF slurry, and the coating thickness is 1 μm.

[0041]Among them, the water-based PVDF slurry contains 10%-12% base material according to weight percentage, and the balance is deionized water. The base material includes the following parts by mass: 10 parts of PVDF resin powder, 0.05 parts of dispersant, 1 part of thickener parts, 0.25 parts of defoamer, 0.5 parts of binder, and 0.25 parts of wetting agent.

Embodiment 2

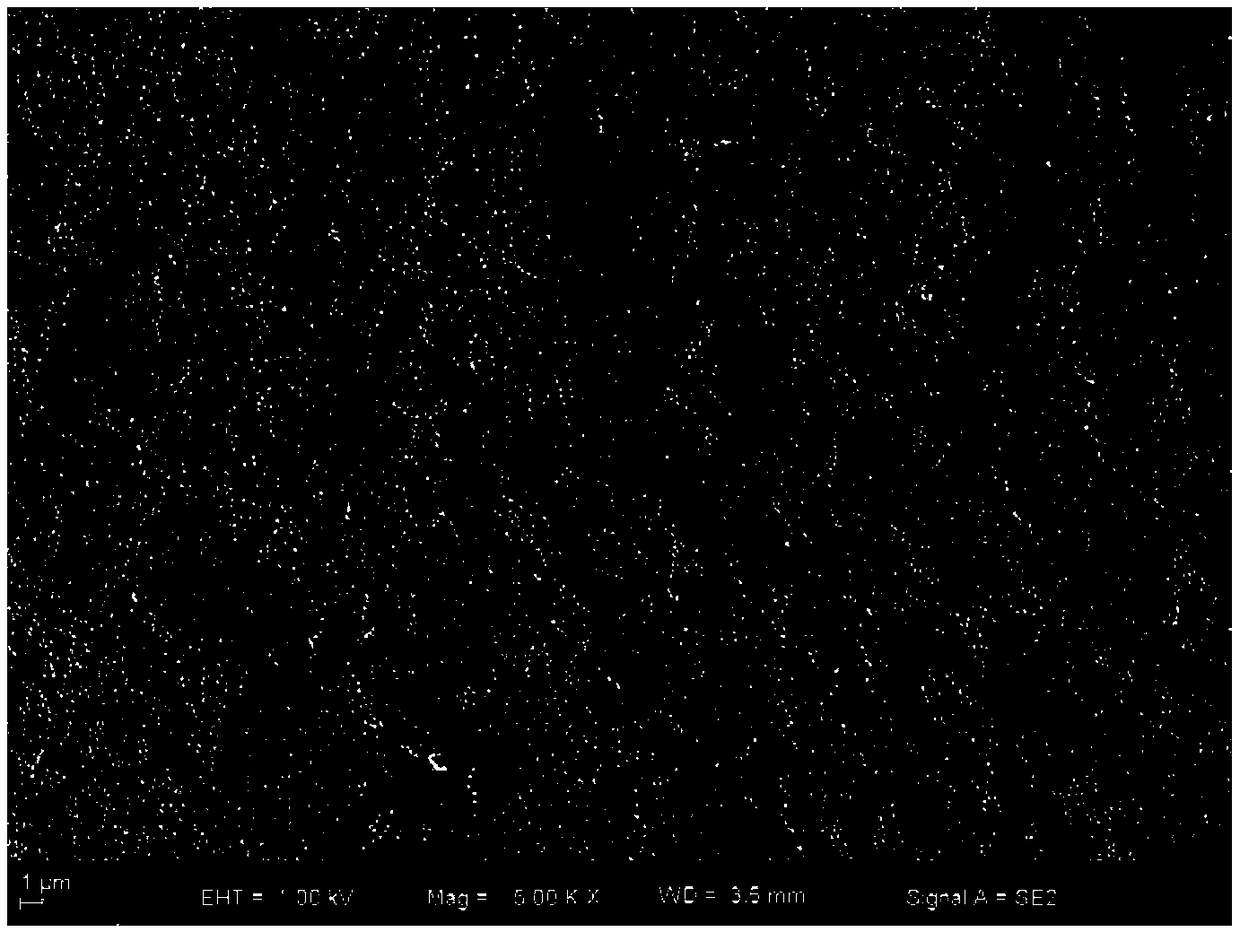

[0043] A lithium-ion battery separator, comprising a base film and a PVDF coating coated on one side or both sides of the base film, the PVDF coating is obtained by coating a water-based PVDF slurry, and the coating thickness is 2 μm.

[0044] Wherein, the water-based PVDF slurry contains 10%-12% base material according to weight percentage, and the balance is deionized water. The base material includes the following materials in parts by mass: 20 parts of PVDF resin powder, 0.8 parts of dispersant, 2 parts of thickener parts, 0.4 parts of defoamer, 0.8 parts of binder, and 0.4 parts of wetting agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com