A contact broadband radio frequency interconnection method and structure

An interconnection structure and contact technology, applied in the direction of connection, fixed connection, conductive adhesive connection, etc., can solve problems such as large thermal stress, difficult integration and repair process, lack of non-destructive testing methods for radio frequency components, etc., to improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

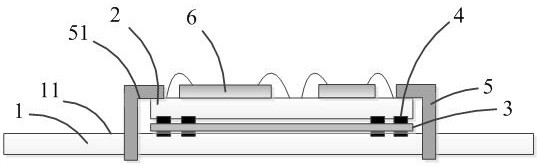

[0031] As an embodiment of the present invention, the flexible conductive material is conductive silicone rubber.

[0032] As an embodiment of the present invention, the method further includes, implementing a fixed contact between the radio frequency component and the radio frequency motherboard by means of screw crimping on the radio frequency component, thereby ensuring the stability of the connection.

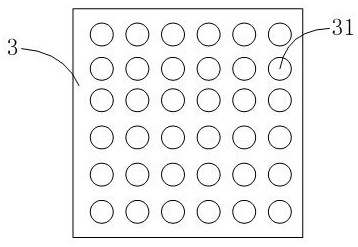

[0033] As an embodiment of the present invention, the method further includes setting an insulating support plate between the radio frequency component and the radio frequency motherboard, limiting the deformation limit of the conductive silica gel within an acceptable range, and ensuring that the screw crimping occurs The pressure does not exceed the pressure limit of the flexible conductive material.

[0034] As an embodiment of the present invention, the insulating support plate is a polytetrafluoroethylene thin plate.

[0035] A contact broadband radio-frequency interc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com