Powder scraping device for high-temperature printing system

A printing system and high-temperature technology, applied in the field of additive manufacturing, can solve the problems of thermal deformation and uneven scraping accuracy, and achieve the effect of improving scraping efficiency, improving scraping accuracy, and occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

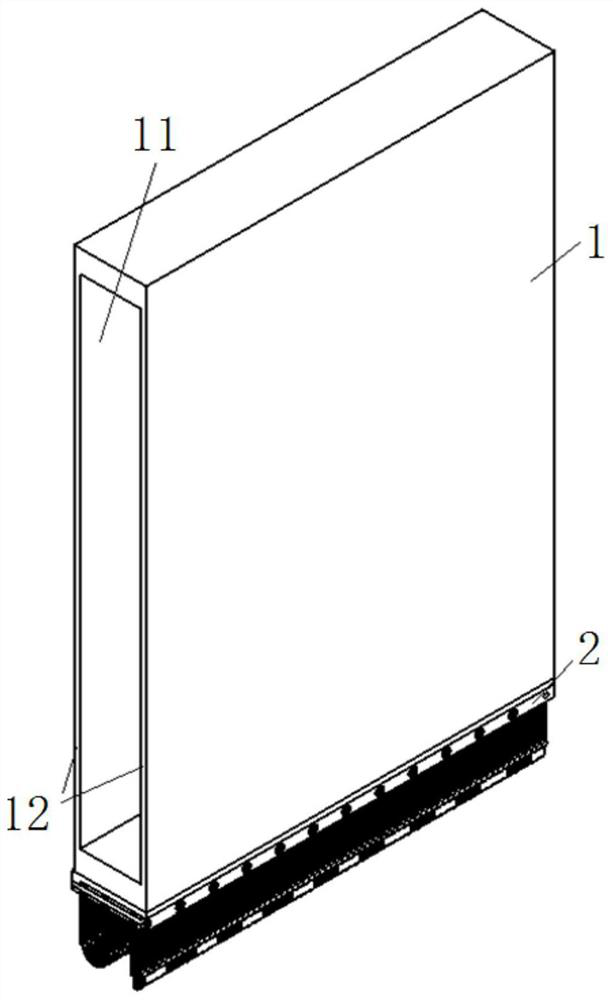

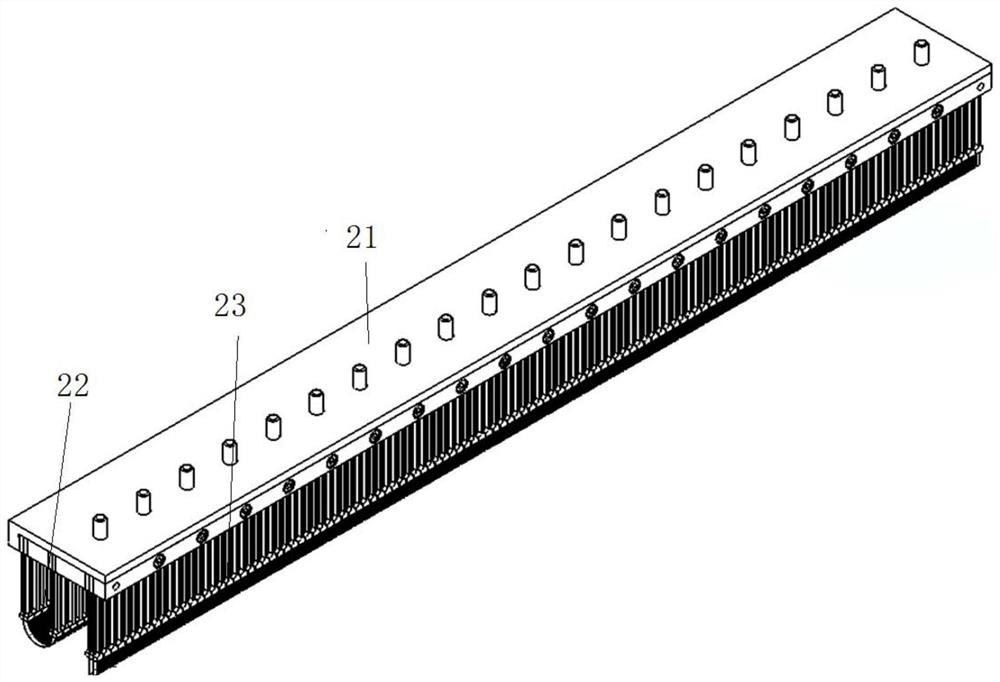

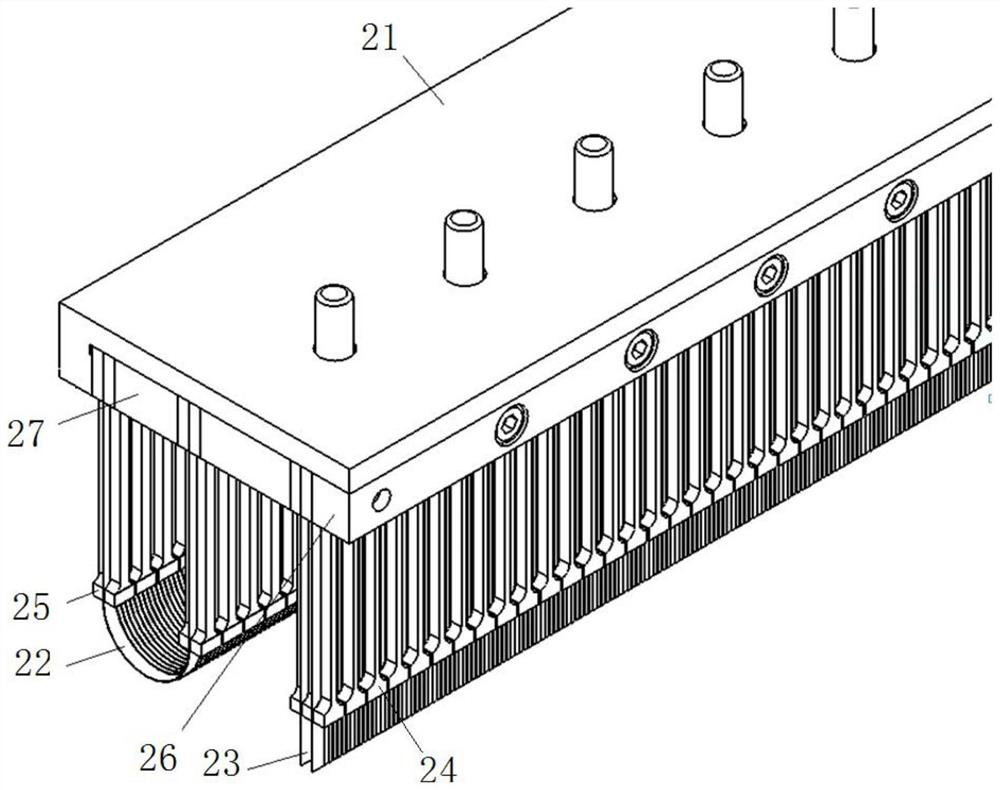

[0029] The invention provides a powder scraping device for a high-temperature printing system. The device is used in large-scale electron beam selective melting (EBSM) equipment, and is used to efficiently, uniformly and accurately spread metal powder on a powder bed and compact it. Get ready for printing. The powder scraping and compacting device of the present invention can cooperate with continuous and uninterrupted printing to realize high-efficiency production and make it possible to realize rapid printing of large-sized and complex parts. At the same time, when the device is used in large-scale electron beam selective melting (EBSM) equipment, it has a compact structure, takes up little space, and saves space in a vacuum printing room, thereby saving equipment cost and vacuuming time.

[0030] Such as figure 1 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com