Preparation method for hemp fimble protein rice noddle with health-care function

A technology of protein rice flour and protein powder, which is applied to the protein components of plant materials, plant protein processing, and protein food ingredients, etc. It can solve the problems of difficulty in maintaining the processing characteristics of rice flour, difficult molding of rice flour, poor fluffiness of rice flour, etc., and achieve good solubility , It is not easy to regenerate, and the effect of increasing the taste of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

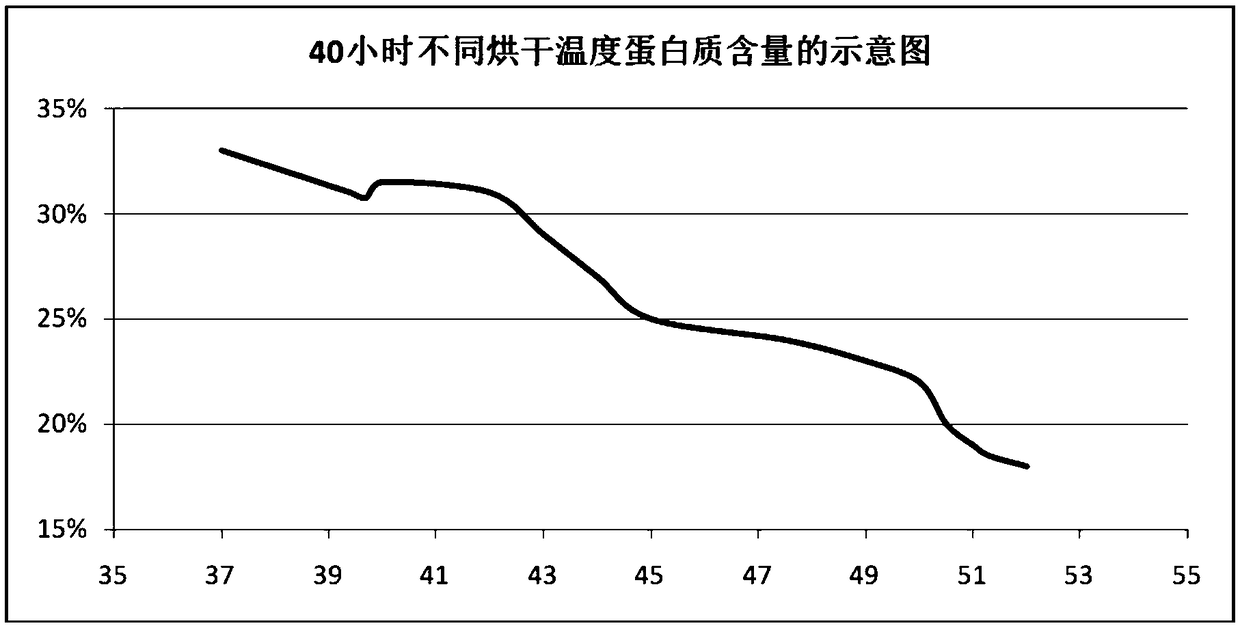

[0045] The processing technology of hemp seed powder comprises the following steps:

[0046] Step 1, preparing the base material, which is formed by mixing hemp seed protein powder, germinated brown rice flour and rice flour, and the weight ratio of each component is as follows: the content of hemp seed protein powder is 15%, and the content of hemp seed protein powder is 15%. Extruded puffed powder 10%, germinated brown rice flour 10%, balance is rice flour.

[0047] Step 2, preparing rice balls, adding an appropriate amount of additives to the base material prepared in Step 1, mixing, adding water or hemp seed meal liquid and stirring to obtain rice balls.

[0048] a. The base material is configured, that is, hemp seed protein powder, germinated brown rice flour, and rice flour are mixed according to a certain proportion. The total protein content in the rice flour prepared by this processing method can reach 20%, up to 25% %. Much higher than the protein content of the ex...

Embodiment 2

[0059] Similar to the above examples, the difference is that the hemp seeds are prepared through the following steps:

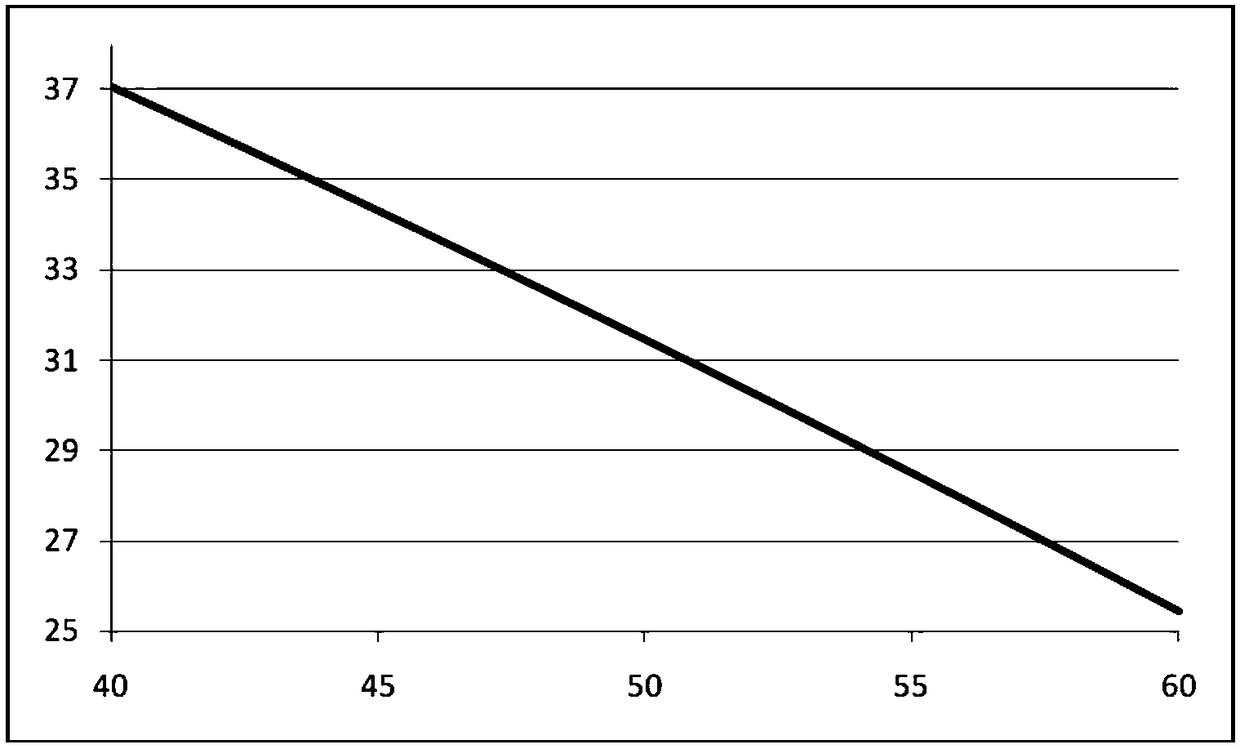

[0060] Spread the hemp seeds obtained after removing impurities and peeling the hemp seeds into a bed of hemp seeds, and dry them at a low temperature at 25.4°C-37.05°C for 40-60 hours, so that the moisture content of the hemp seeds is ≤ 5%; hemp seeds are coarsely crushed, extruded and puffed, then ground and deodorized to obtain the hemp seed fermented material. The relationship between the low-temperature drying time and the drying temperature is:

[0061] T=-0.0021t 2 -0.371t+55.25 60h≥t≥40h; if figure 1 shown;

[0062] Wherein t represents the time, T represents the drying temperature, the thickness of the hemp seed material bed is less than or equal to 2cm, and the surface of the hemp seed material bed is provided with a blower; the wind speed is ≤3m / s.

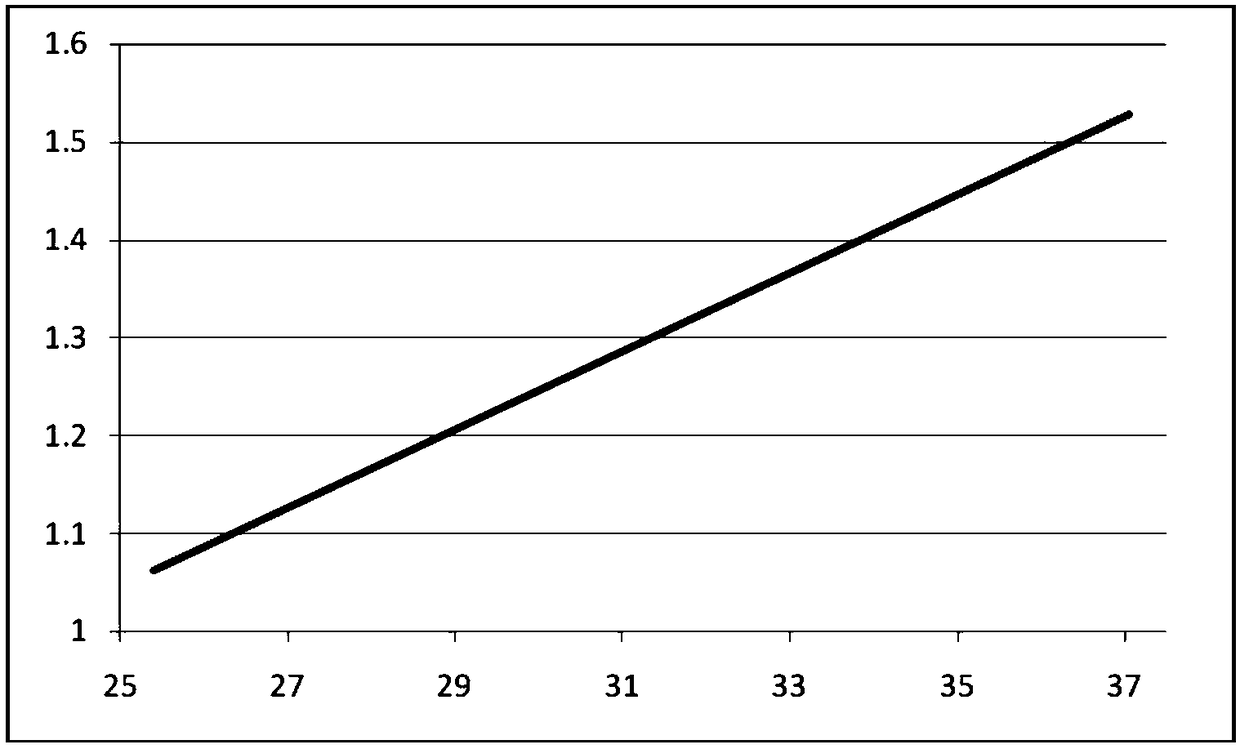

[0063] The relationship between the wind speed of the blower and the drying temperature is

[...

Embodiment 5

[0070] Identical with above embodiment, difference is, described hemp seed is replaced with hemp oil; The preparation process of hemp oil comprises:

[0071] Pretreatment of hemp seeds:

[0072] Microwave pretreatment: Weigh 250g of hemp seeds after removing impurities each time, place them in microwave equipment for dehumidification, when the microwave power is 1000W, the microwave time is 9, 12, 15, 18, 21min respectively; the microwave time is At 15 minutes, the microwave power was 400, 700, 1000, 1300, 1600W respectively. Remove the pre-microwaved hemp seeds and cool to room temperature.

[0073] Infrared pretreatment: put the hemp seeds after each microwave pretreatment in a 20-mesh wire mesh frame, set the temperature of the medium and short-wave infrared drying oven at 140°C, turn on the fan inside the drying oven, and when it is preheated to this temperature, the The barbed wire frame that has hemp seed is put into drying box and is heated, and heating time is 60min....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com