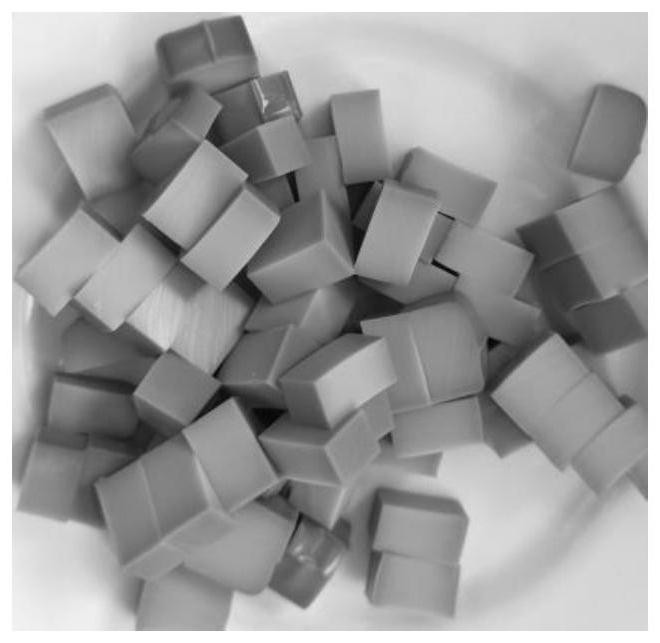

a duck egg

A technology for duck eggs and total egg liquid, applied in the field of dried duck eggs, can solve the problems of increasing the chance of breakage of semi-finished products, increasing soaking and marinating links, and reducing the activity and content of reconstituted egg white protein, so as to reduce the cholesterol content of the finished product and reduce the added salt. Steps, the effect of good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

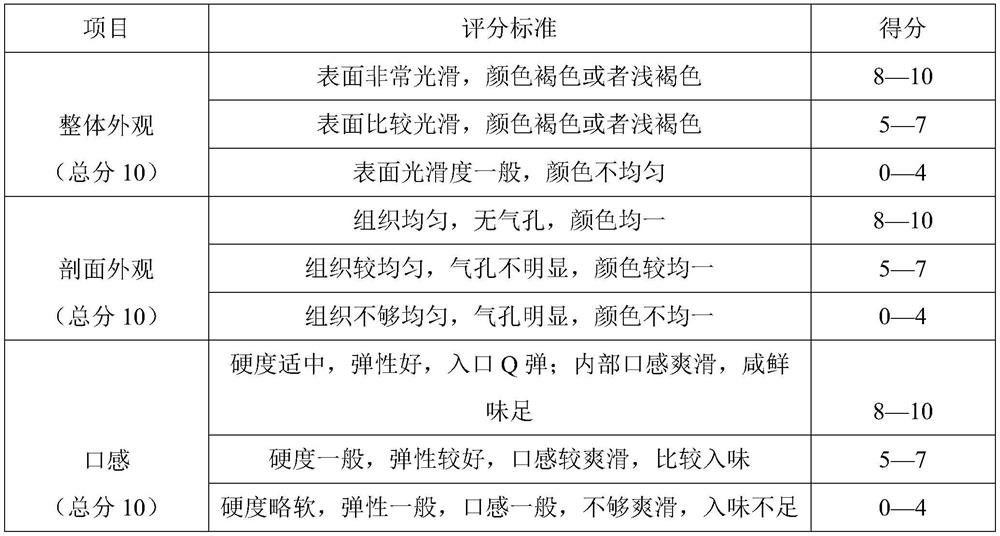

Embodiment 1

[0029] A dried duck egg, which is composed of the following raw and auxiliary materials in parts by weight: 30 parts of salted egg white, 70 parts of duck egg liquid, 0.05 part of chicken essence seasoning, 1 part of white sugar, 0.3 part of compound moisture retaining agent (brittle enhancer), water-soluble 0.1 part of ginger powder, 0.5 part of Haitian straw mushroom dark soy sauce, 0.03 part of five-spice essential oil, 0.1 part of yeast extract, set aside; the preparation method includes the following steps:

[0030] (1) According to the parts by weight and specification requirements of the above-mentioned raw and auxiliary materials, take each raw material, auxiliary materials, etc., and set aside;

[0031] (2) Pretreatment of salted egg white: place the salted egg white at -18°C and freeze it twice for a total of 10 hours. After removing the upper layer of grease and other substances, filter it through a 100-mesh sieve and submit it for inspection (confirm that the salt c...

Embodiment 2

[0036] A dried duck egg, which is composed of the following raw and auxiliary materials in parts by weight: 20 parts of salted egg white, 80 parts of duck egg liquid, 0.1 part of chicken essence seasoning, 3 parts of white sugar, 0.2 part of compound moisture retaining agent (brittle enhancer), water-soluble 0.05 part of ginger powder, 1 part of Haitian straw mushroom dark soy sauce, 0.05 part of five-spice essential oil, 0.2 part of yeast extract, and set aside; the preparation method includes the following steps:

[0037] (1) According to the parts by weight and specification requirements of the above-mentioned raw and auxiliary materials, take each raw material, auxiliary materials, etc., and set aside;

[0038](2) Pretreatment of salted egg whites: place the salted egg whites at -10°C and freeze them 3 times for a total of 12 hours. After removing the upper layer of grease and other substances, use a 100-mesh sieve to pass the inspection and then set aside;

[0039] (3) Mi...

Embodiment 3

[0043] A dried duck egg, consisting of the following raw and auxiliary materials in parts by weight: 10 parts of salted egg white, 90 parts of duck egg liquid, 0.15 part of chicken essence seasoning, 2 parts of white sugar, 0.15 part of a compound moisture retaining agent (brittle enhancer), water-soluble 0.05 part of ginger powder, 1 part of Haitian straw mushroom dark soy sauce, 0.05 part of five-spice essential oil, 0.35 part of yeast extract, set aside; the preparation method includes the following steps:

[0044] (1) According to the parts by weight and specification requirements of the above-mentioned raw and auxiliary materials, take each raw material, auxiliary materials, etc., and set aside;

[0045] (2) Pretreatment of salted egg whites: place the salted egg whites at -15°C and freeze twice for a total of 11 hours. After removing the upper layer of grease and other substances, use a 100-mesh sieve to pass the test and set aside;

[0046] (3) Mix duck egg liquid and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com