1-aminoanthraquinone preparation nitrification device and nitrification process method

An aminoanthraquinone and nitration device technology, which is applied in the direction of nitro compound preparation, control/adjustment process, chemical instruments and methods, etc., can solve the problems of uncontrollable safety risks, temperature rise, large volume, etc., and achieve short reaction time, The effect of small amount and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

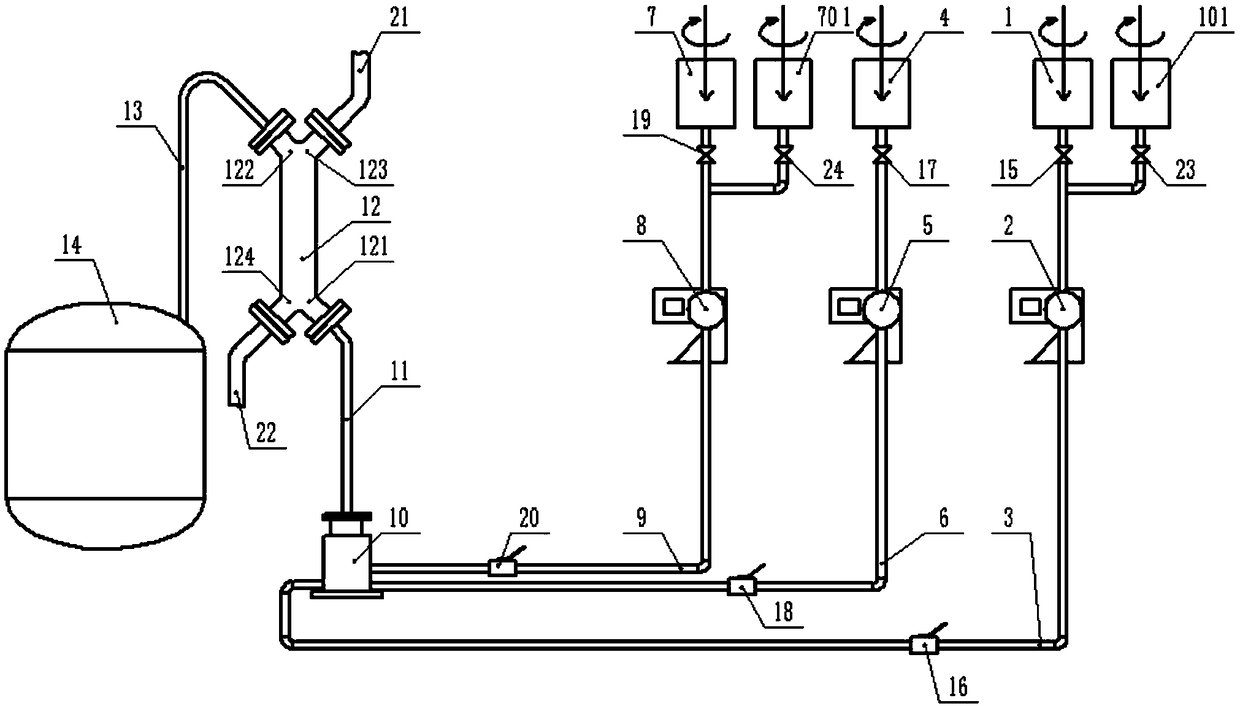

[0025] Such as figure 1 As shown, the present invention provides a nitration device prepared by 1-aminoanthraquinone, comprising an anthraquinone solution reactor 1, a first flow pump 2, a pipeline 3, a concentrated nitric acid solution reactor 4, a second flow pump 5, Pipeline two 6, concentrated sulfuric acid solution reaction kettle 7, third flow pump 8, pipeline three 9, magnetic stirrer 10, pipeline four 11, spiral tube heat exchanger 12, pipeline five 13 and liquid storage tank 14.

[0026] The anthraquinone solution reactor 1 is connected to a first flow pump 2 through a pipeline one 3 , and the first flow pump 2 is connected to a magnetic stirrer 10 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com