A rainy day courier drone

A drone and express delivery technology, applied in the field of drones, can solve the problems of unable to use express delivery normally, poor waterproof performance of drones, and reduced express delivery efficiency, so as to ensure delivery operations, increase waterproof performance, and reduce distribution. heavy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

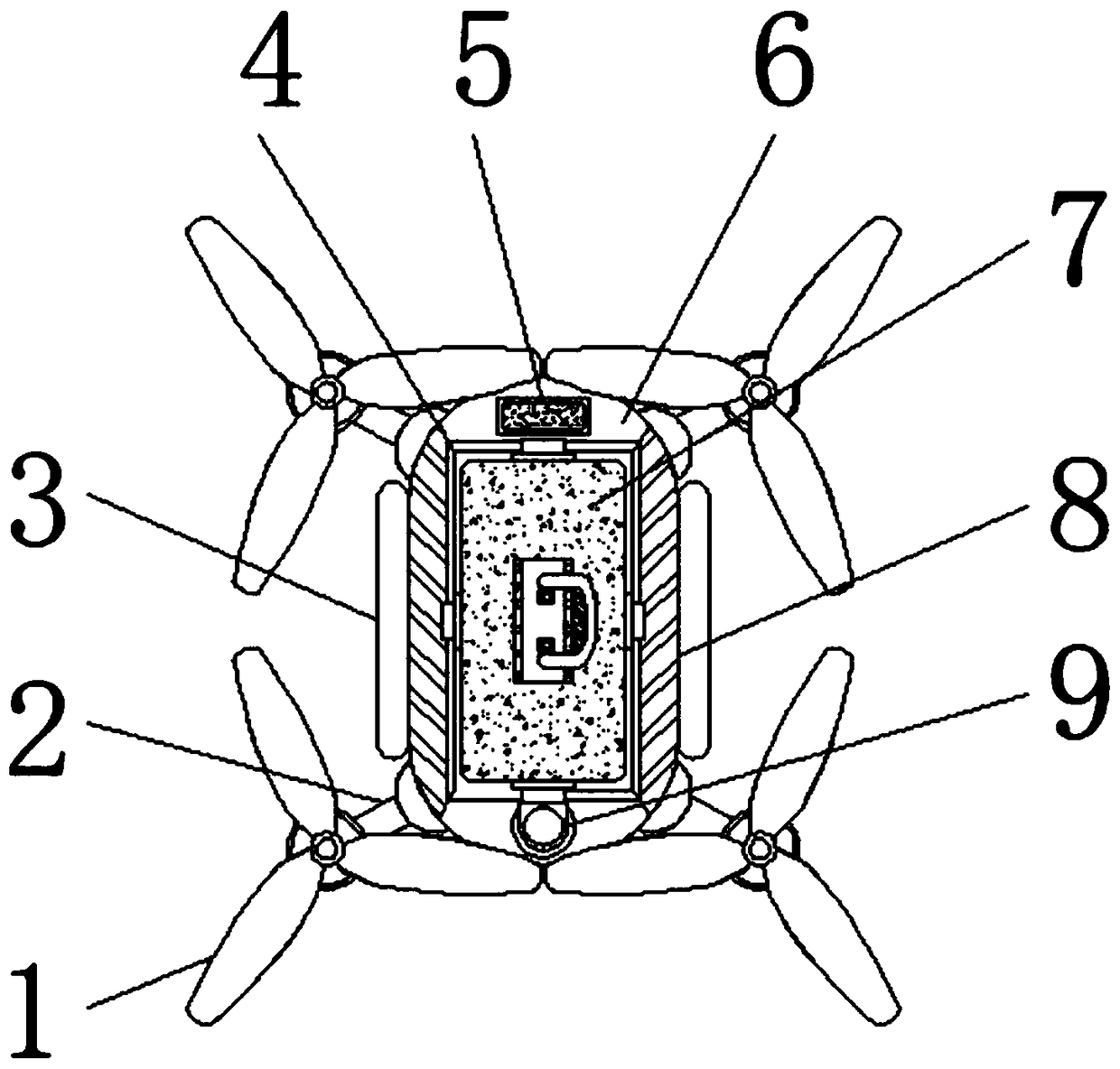

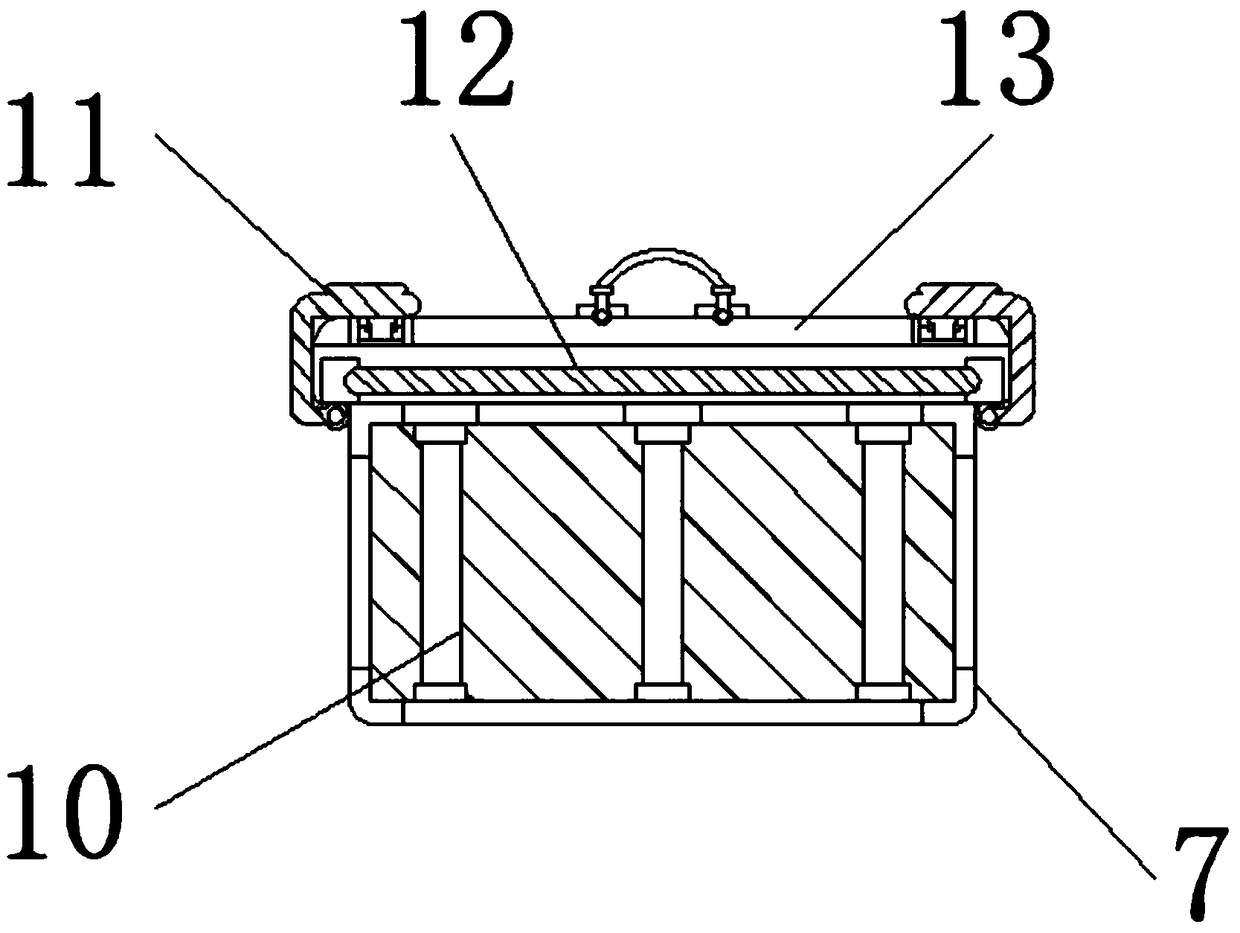

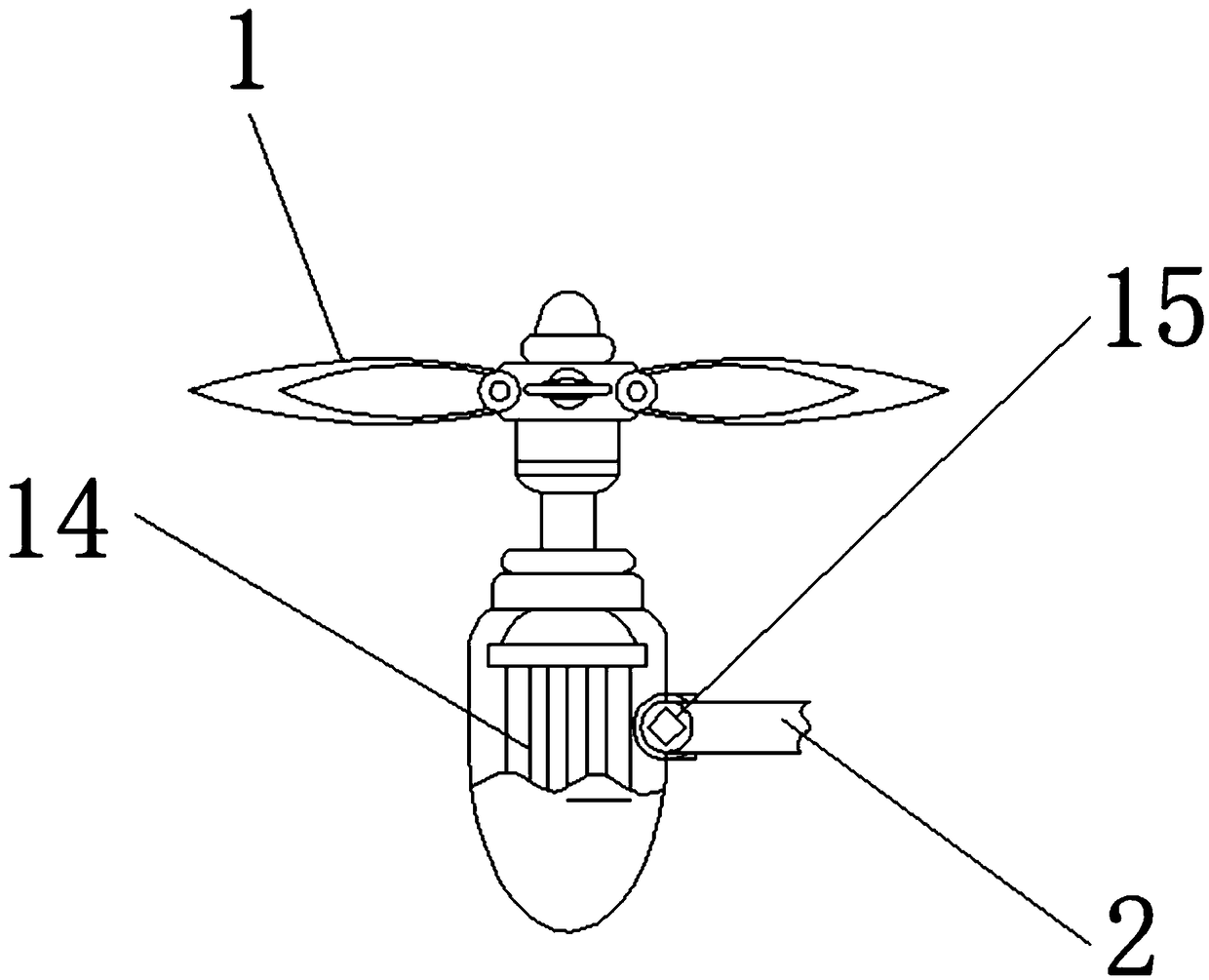

[0027] see Figure 1-3 , the present invention provides a technical solution: a rainy day express delivery drone, comprising a body 6, a waterproof cover 13 and a motor 14, the bottom of the body 6 is provided with a frame 3, the frame 3 is fixedly connected to the body 6, and the body 6 A connecting rod 2 is arranged under the left end of the connecting rod 2, and the connecting rod 2 is fixedly connected with the body 6. The left end of the connecting rod 2 is provided with a flying blade 1, and the flying blade 1 is fixedly connected with the connecting rod 2. The front surface of the body 6 is provided with a waterproof coating. layer 8, the waterproof coating 8 is fixedly connected with the body 6, the inside of the body 6 is provided with a housing tank 4, a display 5 is arranged above the housing tank 4, the monitor 5 is fixedly connected with the body 6, and a sealed box is arranged inside the housing tank 4 7. The sealing box 7 is fixedly connected with the storage ta...

Embodiment 2

[0043] The difference from Example 1 is that a self-made waterproof coating 8 is adopted, and the preparation method of the waterproof coating 8 is:

[0044] Take the following components by weight for subsequent use: 22 parts of polyurethane fiber, 30 parts of methyl isobutyl ketone, 9 parts of talcum powder, 7 parts of barium sulfate, 3 parts of alkyl quaternary ammonium, 17 parts of acrylic emulsion, Sodium alginate 1 part.

[0045] S1. Prefabricated organic solvent: mix polyurethane fiber, methyl isobutyl ketone, and acrylic emulsion, heat to 68°C, stir evenly, and keep warm for 3 hours;

[0046] S2. Preparation of waterproof coating: adding barium sulfate, talcum powder, alkyl quaternary ammonium, and sodium alginate to the organic solvent in S1 in sequence, after stirring evenly, heating the temperature to 72° C. and then keeping it warm for 1 hour;

[0047] S3. Treatment: ultrasonically treat the waterproof coating obtained in S2 for 0.5h, then cool down to 45°C, stir ...

Embodiment 3

[0052] The difference from Example 2 is that the formula specific gravity of waterproof coating 8 is modified and recoated:

[0053] Take the following components by weight for subsequent use: 25 parts of polyurethane fiber, 40 parts of methyl isobutyl ketone, 13 parts of talcum powder, 8 parts of barium sulfate, 4 parts of alkyl quaternary ammonium, 20 parts of acrylic emulsion, Sodium alginate 2 parts.

[0054] S1. Prefabricated organic solvent: mix polyurethane fiber, methyl isobutyl ketone, and acrylic emulsion, heat to 68°C, stir evenly, and keep warm for 3 hours;

[0055] S2. Preparation of waterproof coating: adding barium sulfate, talcum powder, alkyl quaternary ammonium, and sodium alginate to the organic solvent in S1 in sequence, after stirring evenly, heating the temperature to 72° C. and then keeping it warm for 1 hour;

[0056] S3. Treatment: ultrasonically treat the waterproof coating obtained in S2 for 0.5h, then cool down to 45°C, stir at 1200r / min for 0.5h, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com