Biocompatible piezoelectric porous membrane material and preparation method thereof

A Biocompatible, Porous Membrane Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

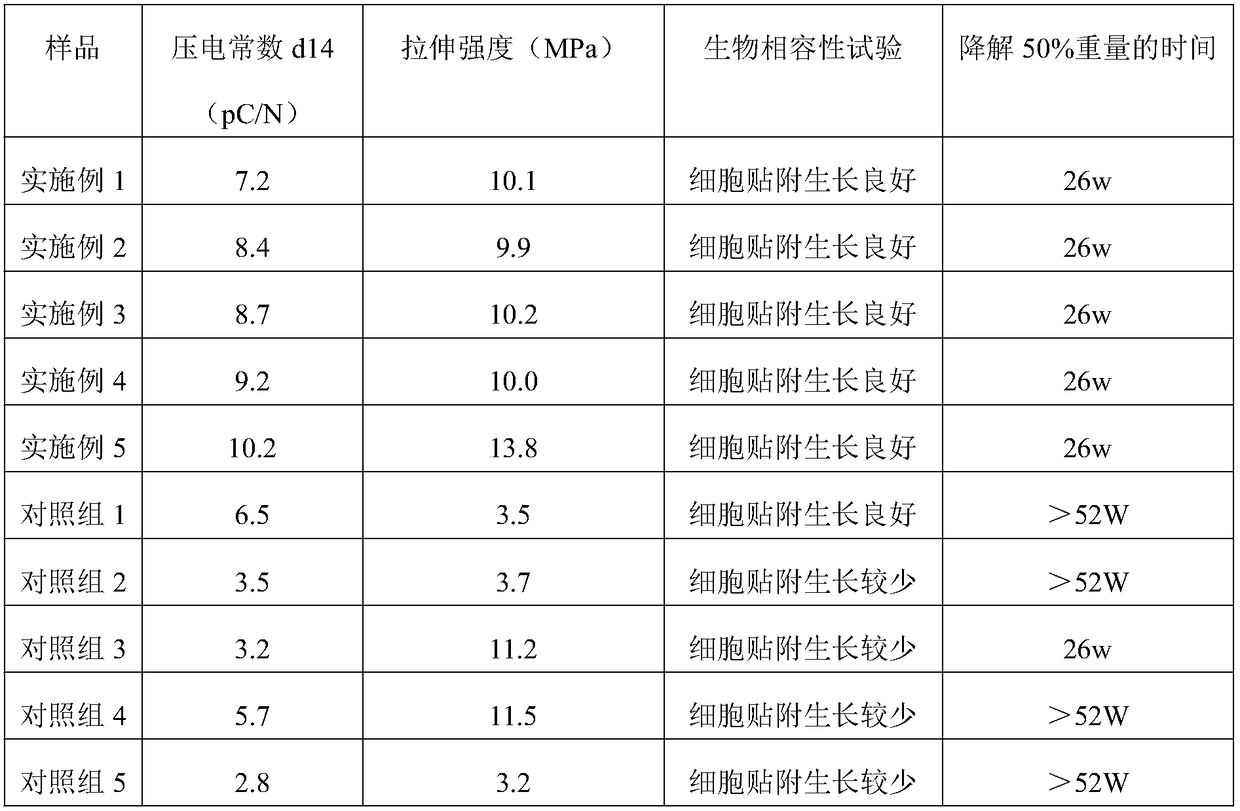

Examples

Embodiment 1

[0032] A biocompatible piezoelectric porous membrane material is prepared, comprising the following steps:

[0033] (1) Weigh according to the required parts by weight: 80 parts of L-polylactic acid, 5 parts of polyhydroxybutyrate, 1 part of gelatin, 1 part of tricalcium phosphate, 5 parts of tourmaline powder, 1 part of montmorillonite, porogen Potassium chloride 5 parts. The molecular weights of poly-L-lactic acid and polyhydroxybutyrate are 5-1 million respectively; tricalcium phosphate is a nano-scale white powdery solid; the particle size of tourmaline powder is 1-10 μm.

[0034] (2) Add the gelatin weighed in step (1) into hot water at 70°C for the first time to stir and dissolve until mixed evenly, then add the tricalcium phosphate weighed in step (1), and then stir and mix for the second time After uniformity, separate and dry to obtain organic film-coated tricalcium phosphate.

[0035] (3) Add the L-polylactic acid and polyhydroxybutyrate weighed in the step (1) int...

Embodiment 2

[0040] A biocompatible piezoelectric porous membrane material is prepared, comprising the following steps:

[0041] (1) Weigh according to the required parts by weight: 100 parts of L-polylactic acid, 20 parts of polyhydroxybutyrate, 20 parts of gelatin, 20 parts of tricalcium phosphate, 20 parts of tourmaline powder, 10 parts of montmorillonite, porogen 40 parts of sucrose. The molecular weights of poly-L-lactic acid and polyhydroxybutyrate are 5-1 million respectively; tricalcium phosphate is a nano-scale white powdery solid; the particle size of tourmaline powder is 1-10 μm.

[0042] (2) Add the gelatin weighed in step (1) into hot water at 100°C for the first stirring and dissolving until it is evenly mixed, then add the tricalcium phosphate weighed in step (1), and then stir and mix for the second time After uniformity, separate and dry to obtain organic film-coated tricalcium phosphate.

[0043] (3) adding the L-polylactic acid and polyhydroxybutyrate weighed in the st...

Embodiment 3

[0048] A biocompatible piezoelectric porous membrane material is prepared, comprising the following steps:

[0049] (1) Weigh according to the required parts by weight: 85 parts of L-polylactic acid, 10 parts of polyhydroxybutyrate, 8 parts of gelatin, 8 parts of tricalcium phosphate, 9 parts of tourmaline powder, 4 parts of montmorillonite, porogen Sodium alginate 21 parts. The molecular weights of poly-L-lactic acid and polyhydroxybutyrate are 5-1 million respectively; tricalcium phosphate is a nano-scale white powdery solid; the particle size of tourmaline powder is 1-10 μm.

[0050] (2) Add the gelatin weighed in step (1) into hot water at 80°C for the first stirring and dissolving until it is evenly mixed, then add the tricalcium phosphate weighed in step (1), and then stir and mix for the second time After uniformity, separate and dry to obtain organic film-coated tricalcium phosphate.

[0051] (3) Add the L-polylactic acid and polyhydroxybutyrate weighed in the step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com