Floor with transverse wood grain and longitudinal wood grain

A vertical wood grain, horizontal technology, applied in the direction of floor, construction, adhesive, etc., can solve the problems of low floor strength, easy cracking of boards, low bonding strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

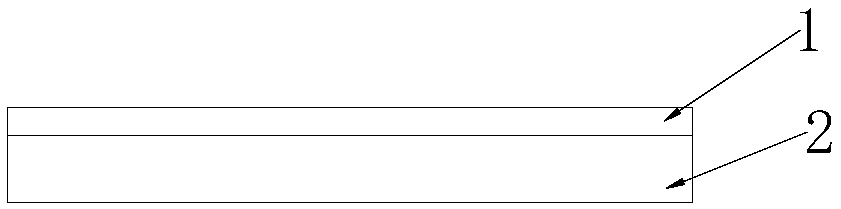

[0021] refer to Figure 1 to Figure 8 , this embodiment discloses a floor with transverse wood grain and longitudinal wood grain, comprising a panel 1 and a base material 2 arranged sequentially from top to bottom, and a formaldehyde-free barrier is passed between the panel 1 and the base material 2. Burning glue is used for bonding and fixing.

[0022] The surface layer of the panel 1 is provided with wood grains produced by wiping chemical reagent changes, which are more natural than traditional wiping colored paints, and the color changes are more vivid and rich; as preferred, the chemical reagents are not highly corrosive, safe, and non-toxic. Toxic water agents, such as copper sulfate, ferric chloride, etc., have the advantages of good coloring effect and economic benefits.

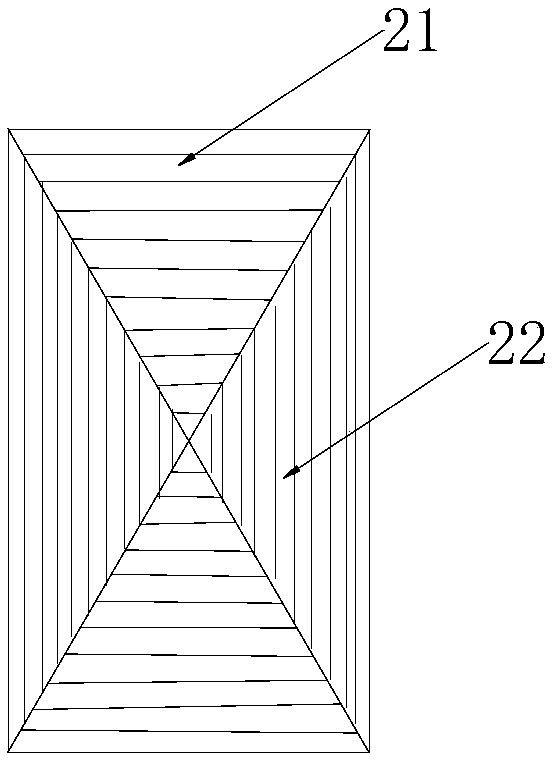

[0023] The substrate 2 includes a protruding transverse wood grain substrate 21 and a protruding longitudinal wood grain substrate 22, the transverse wood grain substrate 21 and the longitudinal woo...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the horizontal wood grain substrate 21 is two symmetrically arranged quadrilateral structures, and the two sides of the horizontal wood grain substrate 21 are symmetrical vertical wood grain substrates 22 with a triangular structure.

[0029] refer to Figure 4 , the transverse wood-grain substrate 21 is two symmetrically arranged isosceles trapezoidal structures, and the two sides of the transverse wood-grain substrate 21 are symmetrical vertical wood-grain substrates 22 with a triangular structure.

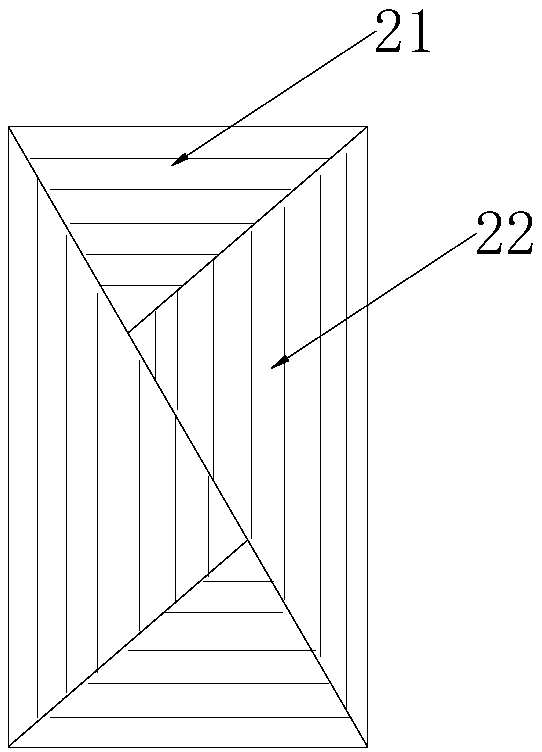

[0030] refer to Figure 5 , the transverse wood grain substrate 21 is two symmetrically arranged right-angled trapezoidal structures, and the two sides of the transverse wood grain substrate 21 are symmetrical vertical wood grain substrates 22 with a right-angled triangular structure.

Embodiment 3

[0032] The difference between this embodiment and the second embodiment is that the transverse wood grain substrate 21 is two symmetrically arranged quadrilateral structures, and the two sides of the transverse wood grain substrate 21 are symmetrical longitudinal wood grain substrates 22 with quadrilateral structures.

[0033] refer to Figure 6 , the transverse wood-grain substrate 21 is two symmetrically arranged parallelogram structures, and the two sides of the transverse wood-grain substrate 21 are symmetrical longitudinal wood-grain substrates 22 with a parallelogram structure; the parallelogram structure can also be Any one of rhombus, rectangle and square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com