PAA bi-crosslinking network self-healing hydrogel capacitive pressure sensor

A pressure sensor, hydrogel technology, applied in instruments, measuring force, measuring devices, etc., can solve the problems of restricted hydrogel development, unsatisfactory comprehensive properties, etc., to enhance tensile properties and self-healing ability , Excellent self-healing ability, short production cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

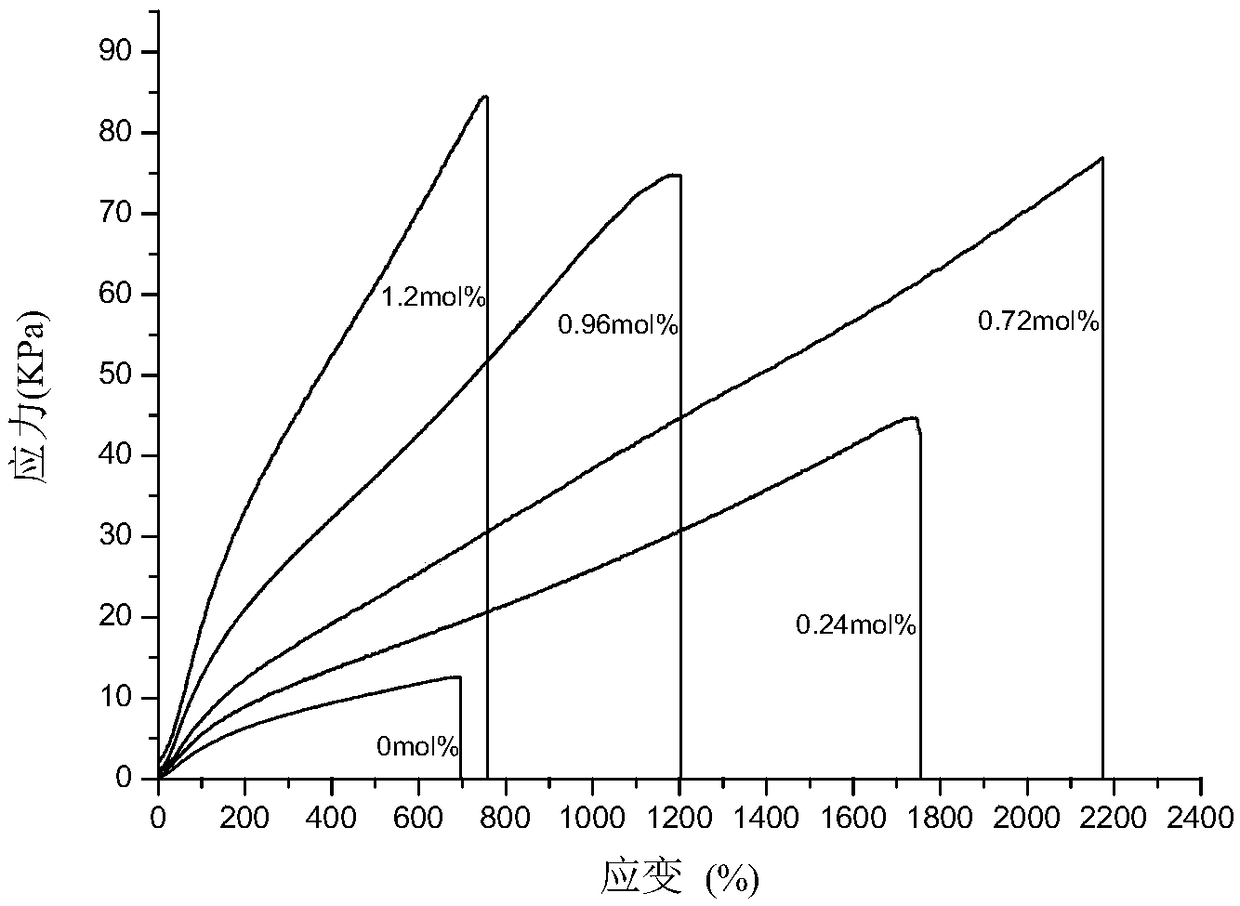

Embodiment 1

[0024] Take 2g of acrylic acid, 0.05g of acrylamide, 4mg of MBAA, 10mg of APS, and add 0-1.2mol% of FeCl relative to the amount of acrylic acid 3 ·6H 2 O, stir in 10mL of aqueous solution for 30 minutes and mix well, pass nitrogen gas for 30 minutes to remove the gas in the solution, pour the solution into a polytetrafluoroethylene mold, polymerize at 60°C for 30 minutes, and obtain different Fe 3+ concentrated hydrogel. When the content of acrylamide is 0g, FeCl 3 ·6H 2 When the O content is 0.72mol%, it is labeled as PAA / Fe 3+ Hydrogel; when the acrylamide content is 2.5wt%, FeCl 3 ·6H 2 When the O content is 0 mol%, it is labeled as PAA-PAM hydrogel.

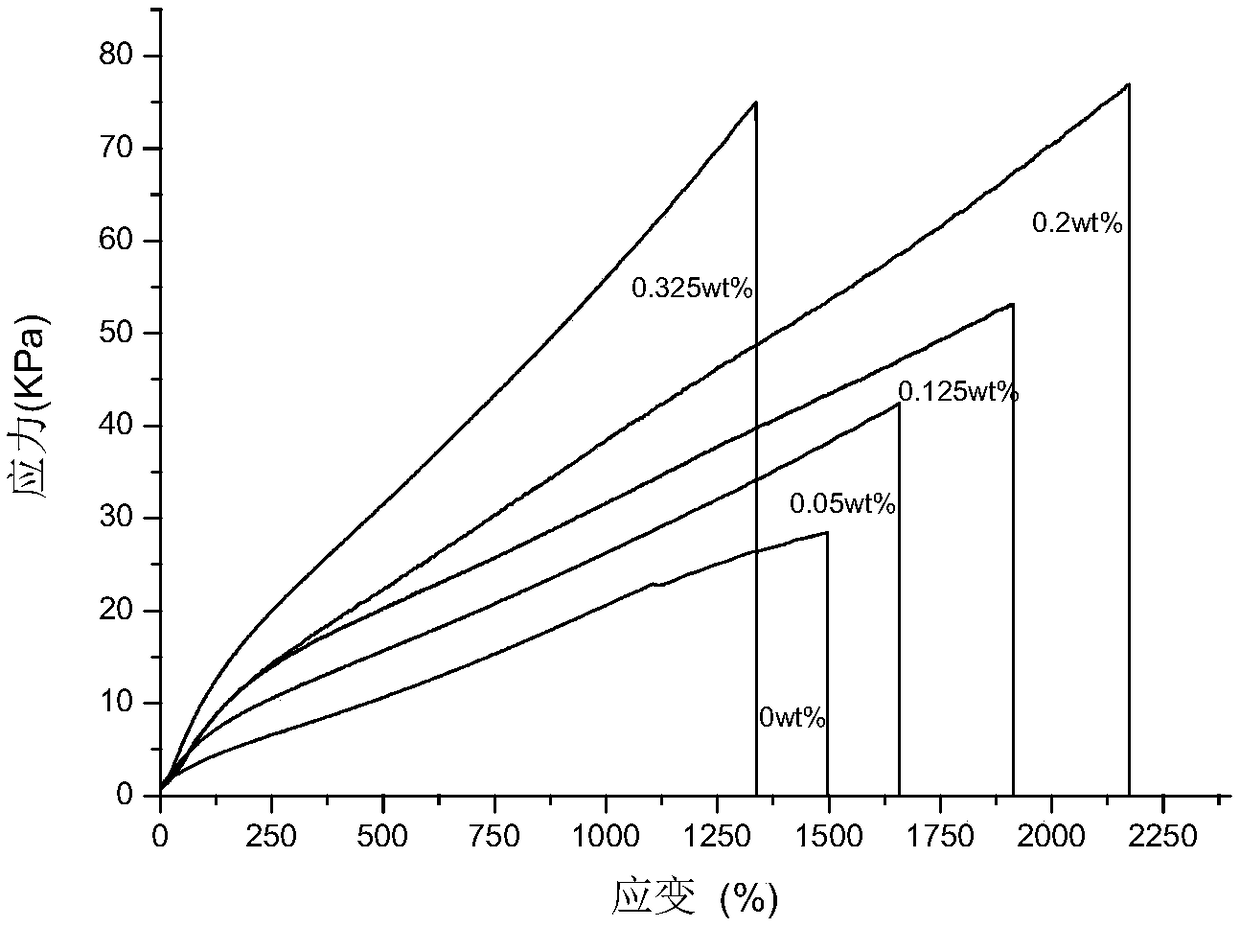

Embodiment 2

[0026] Change Example 1 to get 2g acrylic acid, 0.05g acrylamide, 10mg APS, 0.054g FeCl 3 ·6H 2 O, the content of MBAA added is 0-0.325wt% relative to the mass of acrylic acid. After stirring in 10mL of aqueous solution for 30 minutes and mixing evenly, nitrogen gas is passed for 30 minutes to remove the gas in the solution. Polymerization takes place at 60°C for 30 minutes to obtain different The hydrogel of MBAA concentration, all the other steps are identical with embodiment 1.

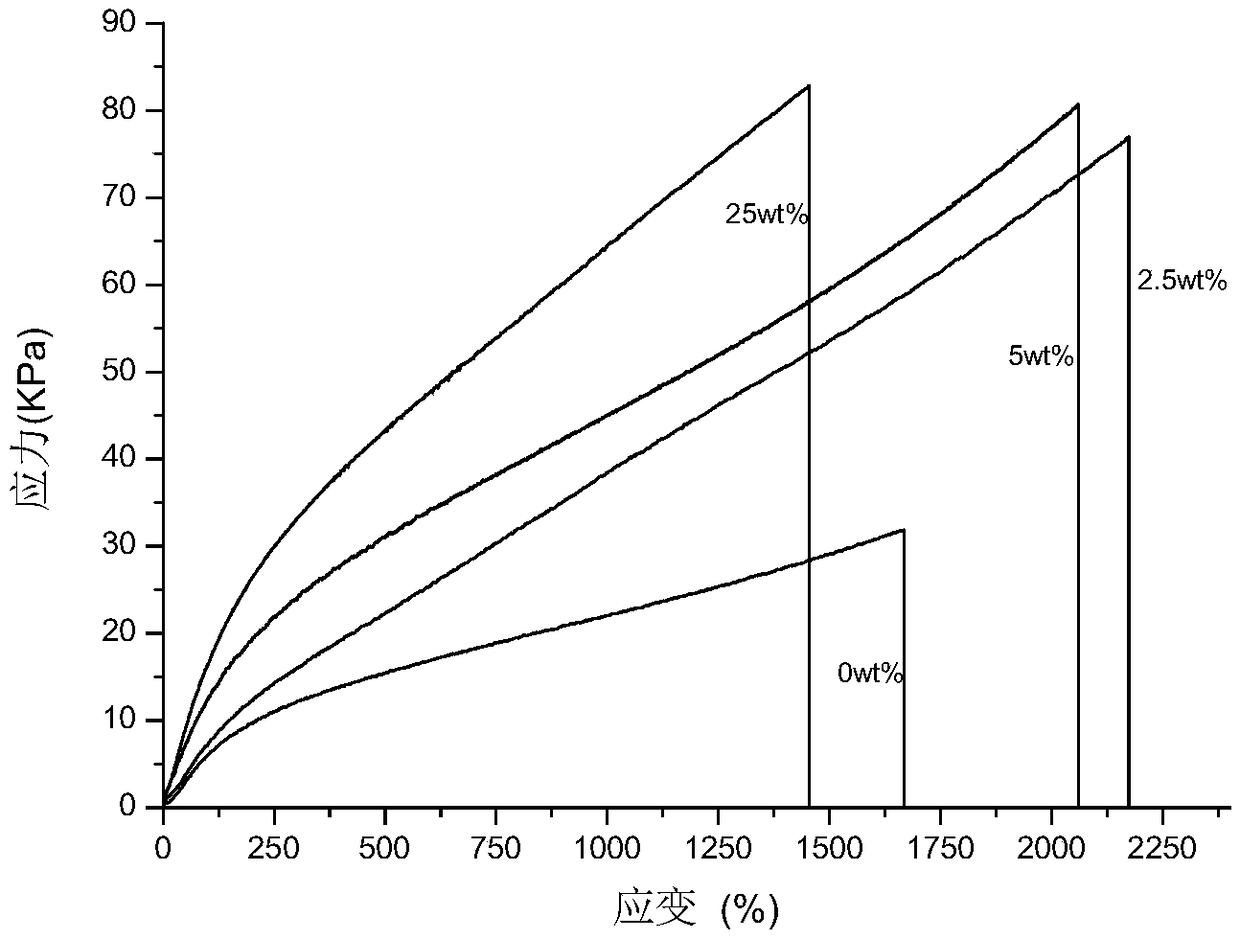

Embodiment 3

[0028] Change Example 1 to get 2g acrylic acid, 4mg MBAA, 10mg APS, 0.054g FeCl 3 ·6H 2O, the content of adding acrylamide is 0-25wt% relative to the mass of acrylic acid. Stir in 10mL of aqueous solution for 30 minutes and mix evenly, then pass nitrogen gas for 30 minutes to remove the gas in the solution, and polymerize at 60°C for 30 minutes to obtain different The hydrogel of acrylamide concentration, other steps are identical with embodiment 1. When the acrylamide content is 2.5wt%, FeCl 3 ·6H 2 When the O content is 0.72mol%, it is labeled as PAA-PAM / Fe 3+ Hydrogels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com