Automatic teller machine for taking and changing patient dresses

A technology for self-service teller machines and patient clothes, which is applied in the field of self-service teller machines for changing patient clothes, which can solve the problems of increased manpower input, loss, and increased patient dissatisfaction, and achieves the effect of easy access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

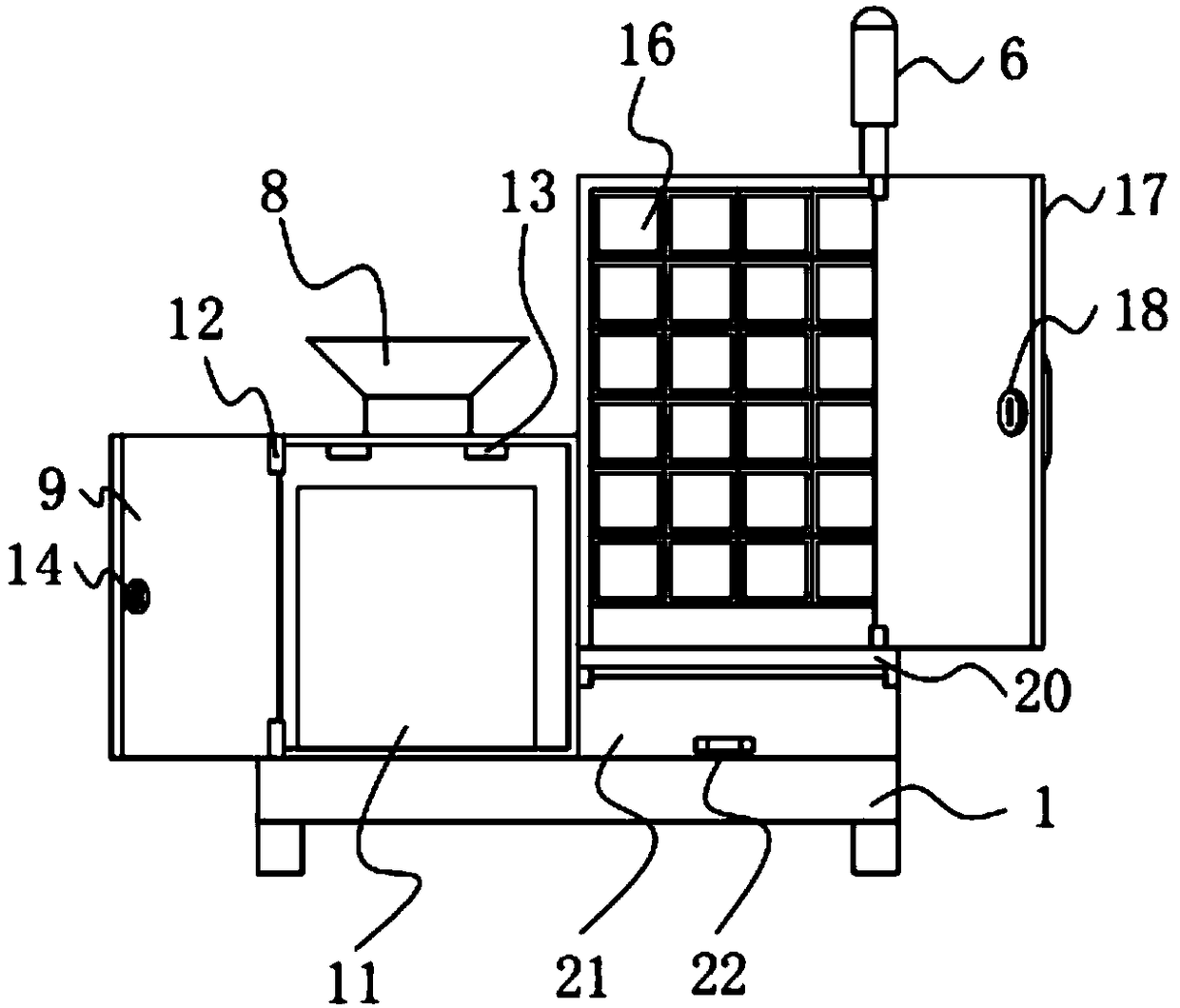

[0064] The following is attached Figure 1-18 The present invention is described in further detail.

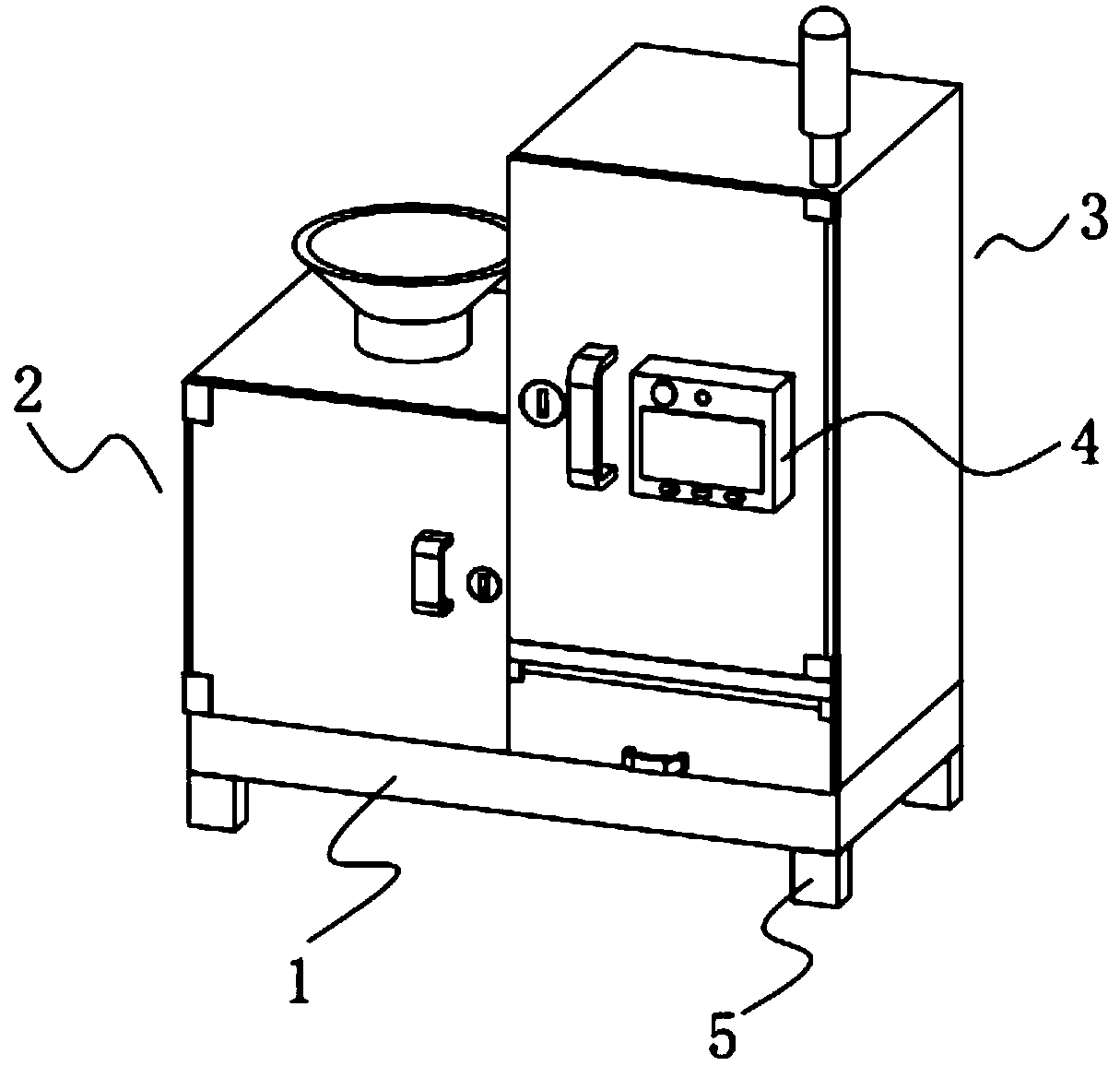

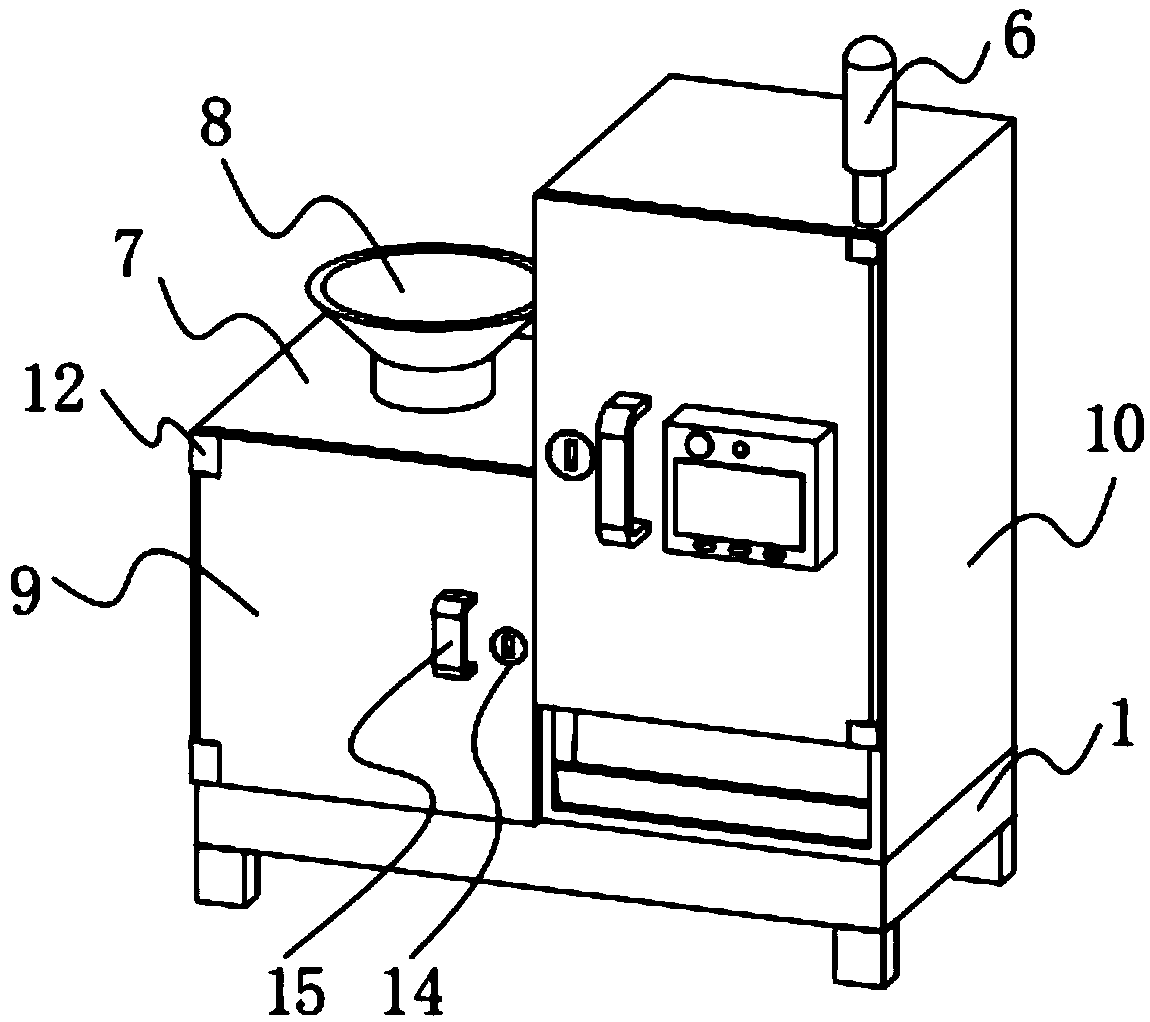

[0065] A self-service teller machine for taking and changing patient clothes, such as Figure 1-18 As shown, it includes a bottom plate 1, and the upper part of the bottom plate 1 is provided with a recovery part 2 and a supply part 3 side by side;

[0066] The recovery part 2 includes a square casing 7 fixedly installed on the upper side of the bottom plate 1, the top of the square casing 7 is communicated with a funnel-shaped inlet 8, and the inside of the square casing 7 is detachable A recovery bucket 11 is provided, and the front part of the square housing 7 is equipped with a door panel 9 through a hinge 12, and the bottom of the inner top wall of the square housing 7 is symmetrically installed on both sides of the funnel-shaped inlet 8 two first sensors 13;

[0067] The supply part 3 includes a cabinet body 10 fixedly installed on the other side of the upper part of ...

Embodiment 2

[0082] The difference from Example 1 is that the inner and outer surfaces of the square housing 7 and the funnel-shaped inlet 8 are provided with an anti-corrosion layer, and the anti-corrosion layer is prepared by the following method:

[0083] Take the following raw materials and weigh them by weight: 20 parts of porcelain powder, 10 parts of aluminum oxide powder, 10 parts of phenolic resin, 6 parts of mica powder, 8 parts of epoxy resin, 7 parts of calcium carbonate powder, 2 parts of propylene glycol methyl ether acetate 3 parts of BDMA, 4 parts of polydimethylsiloxane emulsion, 1 part of zirconate coupling agent and 40 parts of methanol;

[0084] S1. Add the weighed propylene glycol methyl ether acetate, BDMA, polydimethylsiloxane emulsion, zirconate coupling agent and methanol into the mixer and stir for 18min at a stirring speed of 600r / min to prepare a mixed solution ;

[0085] S2, adding porcelain powder, aluminum oxide powder, phenolic resin, mica powder, epoxy res...

Embodiment 3

[0091] The difference from Example 2 is the preparation of the anti-corrosion layer, and its specific preparation method is as follows:

[0092] Take the following raw materials and weigh them by weight: 25 parts of porcelain powder, 12 parts of aluminum oxide powder, 13 parts of phenolic resin, 8 parts of mica powder, 10 parts of epoxy resin, 9 parts of calcium carbonate powder, 3 parts of propylene glycol methyl ether acetate 4 parts of BDMA, 5 parts of polydimethylsiloxane emulsion, 2 parts of zirconate coupling agent and 50 parts of methanol;

[0093] S1. Add the weighed propylene glycol methyl ether acetate, BDMA, polydimethylsiloxane emulsion, zirconate coupling agent and methanol into the mixer and stir for 23min at a stirring speed of 700r / min to prepare a mixed solution ;

[0094] S2, adding porcelain powder, aluminum oxide powder, phenolic resin, mica powder, epoxy resin and calcium carbonate powder into a ball mill for fine grinding until the particle diameter is 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com