An infrared thermal imager autofocus system and method with temperature compensation

An infrared thermal imager and temperature compensation technology, which is applied in the parts of TV systems, image communication, parts of color TV, etc. failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

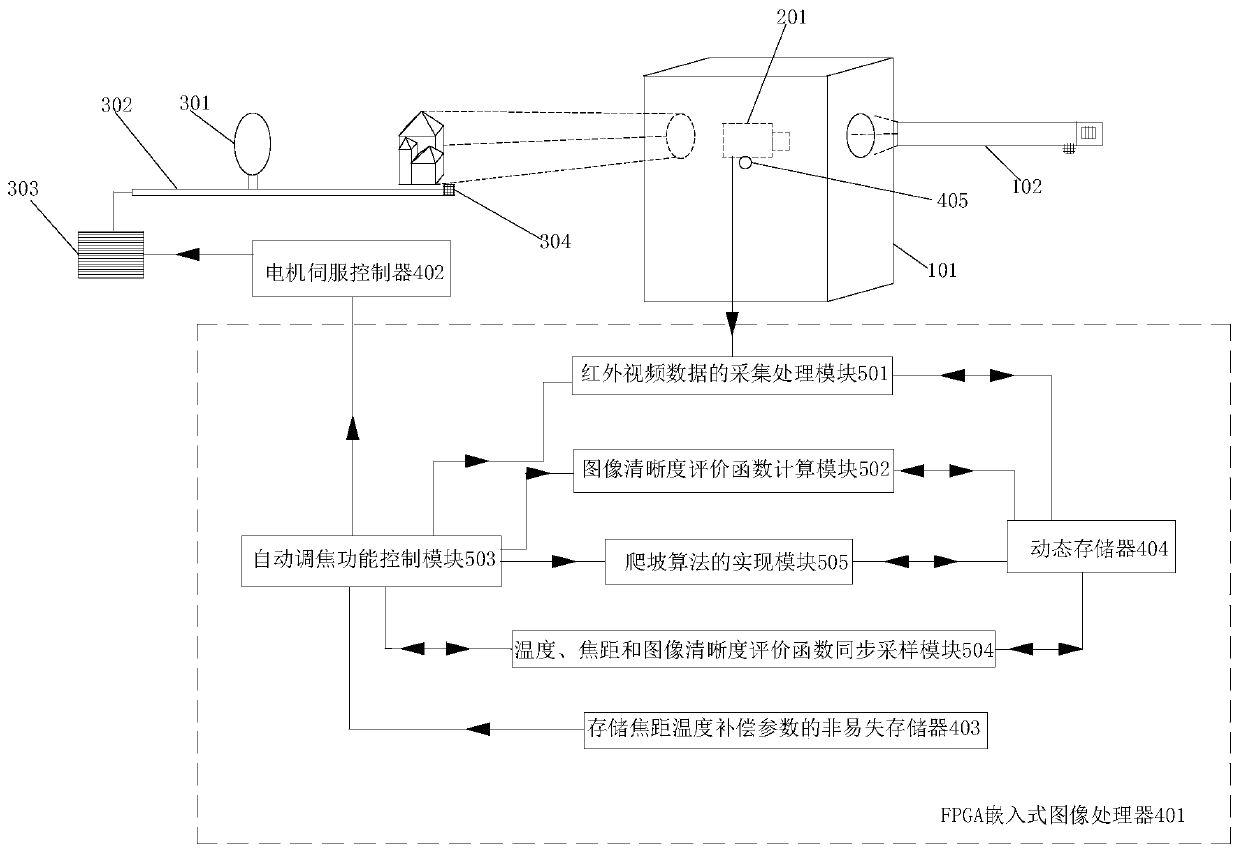

[0056] An automatic focusing system of an infrared thermal imager with temperature compensation, comprising: a high and low temperature environment experiment box 101, a collimator 102, an infrared thermal imager 201, a focusing mirror 301, a sliding screw rod 302 for the focusing mirror, and a focusing motor 303, screw position sensor 304, FPGA embedded image processor 401, motor servo controller 402 and thermal imager complete machine temperature sensor 405;

[0057] The infrared thermal imager 201 is placed in the high and low temperature environment test box 101, and the two sides of the high and low temperature environment test box 101 are provided with openings as observation windows. to the scene;

[0058] The control terminal of the motor servo controller 402 is connected with the focus motor 303, and is used to control the work of the focus motor 303;

[0059] The power output end of the focusing motor 303 links to each other with the sliding screw rod 302 of the foc...

Embodiment 2

[0080] An automatic focusing system of an infrared thermal imager with temperature compensation, comprising: a high and low temperature environment experiment box 101, a collimator 102, an infrared thermal imager 201, a focusing mirror 301, a sliding screw rod 302 for the focusing mirror, and a focusing motor 303, screw position sensor 304, FPGA embedded image processor 401, motor servo controller 402 and thermal imager complete machine temperature sensor 405;

[0081] The infrared thermal imager 201 is placed in the high and low temperature environment test box 101, and the two sides of the high and low temperature environment test box 101 are provided with openings as observation windows. to the scene;

[0082] The control terminal of the motor servo controller 402 is connected with the focus motor 303, and is used to control the work of the focus motor 303;

[0083] The power output end of the focusing motor 303 links to each other with the sliding screw rod 302 of the foc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com