Epoxy resin composition and electronic component device

A technology of epoxy resin and composition, which is applied in the field of epoxy resin composition and electronic components and devices, can solve the problems of packaging cracks and poor electrical characteristics, and achieve the effects of excellent reflow soldering resistance and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0198]

[0199] The epoxy resin composition may be prepared by any method as long as various raw materials can be uniformly dispersed and mixed. As a general preparation method, the following method can be cited: After fully mixing the raw materials in a predetermined amount with a mixer, etc., they are mixed or melt-kneaded with a grinding roll, extruder, crushing machine, planetary mixer, etc., and cooled. , Degassing and pulverization as needed. In addition, the epoxy resin composition can also be made into small pieces (Japanese: tablet) with a size and quality that meet the molding conditions as needed.

[0200]

[0201] An electronic component device according to one embodiment of the present invention includes an element and a cured product of the epoxy resin composition that seals the element. As a method of sealing an element using the epoxy resin composition of the present embodiment as a sealing material, low-pressure transfer molding is generally used, but inj...

Embodiment

[0206] Next, the present invention will be described using synthesis examples and examples, but the scope of the present invention is not limited to these examples.

Synthetic example 1~4

[0208] Specific epoxy resins can be synthesized as follows.

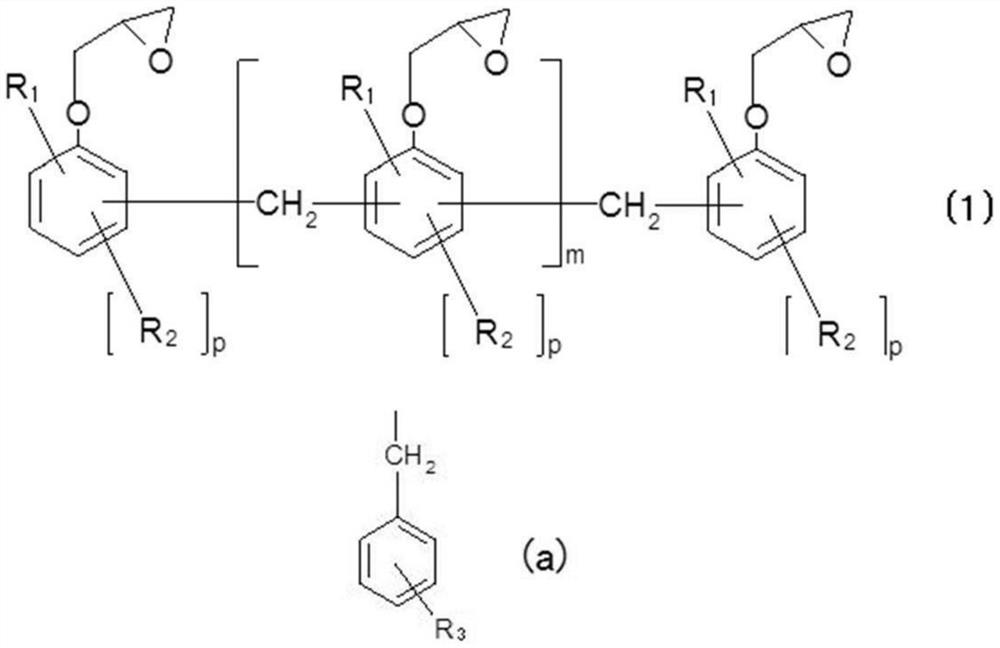

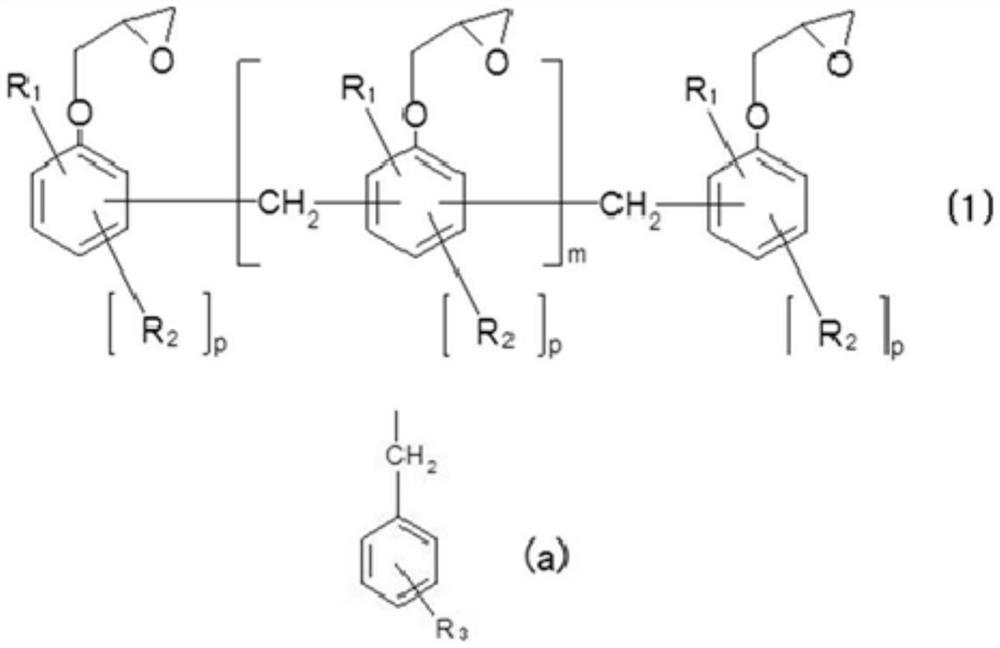

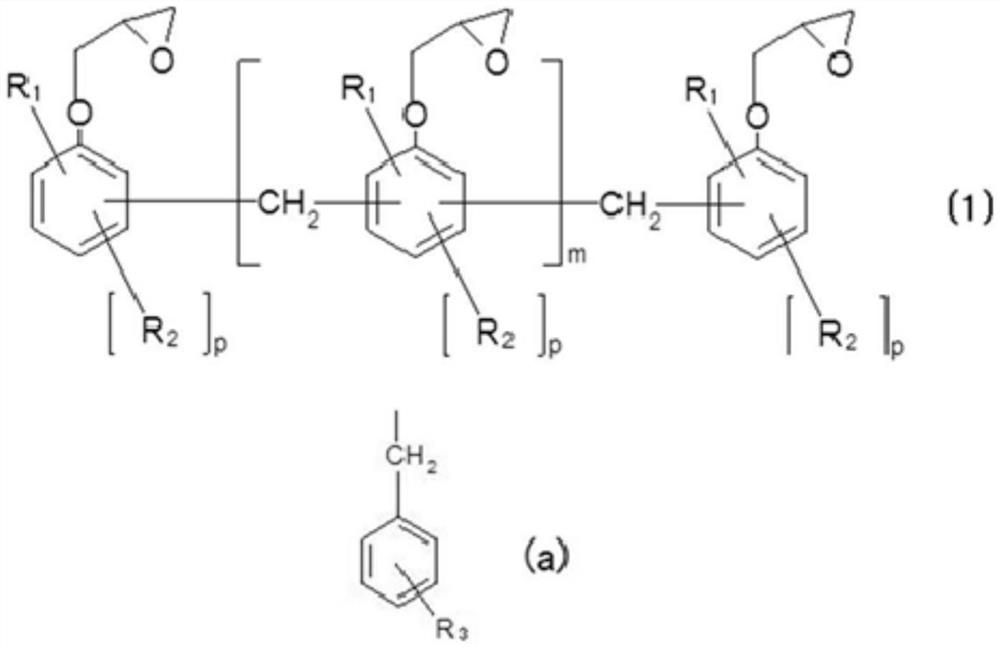

[0209] First, a raw material phenol novolak resin and a raw material benzyl group-containing compound are reacted using p-toluenesulfonic acid as an acid catalyst to obtain a specific phenol novolac resin. At this time, the hydroxyl equivalent is measured in the same manner as the method for measuring the hydroxyl equivalent in the curing agent described above, and the value of p in the general formula (1) is obtained from this value.

[0210] Next, the specific phenol novolak resin obtained above was epoxidized with epichlorohydrin. The epoxy equivalent, softening point, and melt viscosity at 150° C. of the obtained resin are shown in Table 1 below. It should be noted that in the specific epoxy resin obtained, R in the general formula (1) 2 is benzyl (R 3 to a hydrogen atom).

[0211] [Table 1]

[0212]

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com